CAM Improves Programming of Multitasking Machines

By investing in Esprit CAM software from DP Technology, French manufacturer Lathuille-Hudry was able to take full advantage of programming its multitasking machines to produce complex geometries.

Share

For French manufacturer Lathuille-Hudry, specializing in high-precision machining often involves producing parts with complex geometries on multitasking machines. However, until 10 years ago, the company’s ability to make increasingly complicated parts was limited by traditional, manual programming. By investing in CAM software from DP Technology (Camarillo, California), the company is able to produce more sophisticated parts and increase productivity.

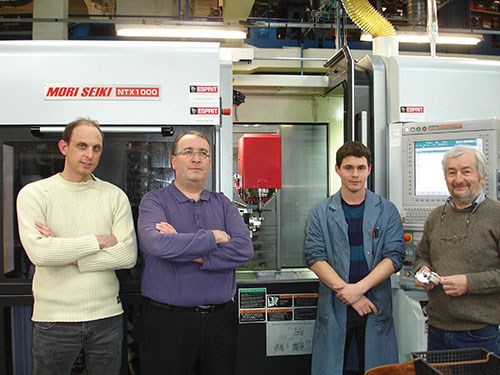

Founded in 1956, Lathuille-Hudry set up its first workshop in the Upper Savoy region of France, bordering Switzerland. Today, 60 employees work in more than 40,000 square feet of space and operate Mori Seiki CNC machines. The company specializes in short and medium runs of parts ranging to 200 and 65 mm in diameter, respectively, in geometries including long, small, round, parallelepiped, and bent, among others. These parts predominantly are made from stainless steel and used in the industrial, aeronautics and medical industries.

Lathuille-Hudry also works with its customers’ design offices to develop prototypes and quickly move toward serial production. Common problems the company faces while developing high-precision parts often include achieving the required surface finish, machining difficult materials and machining complex shapes. These challenges are addressed using all of the company’s machines, including fixed headstock, sliding headstock, three-axis turning centers, five-axis turning centers and multitasking machines.

However, the right machine tools were only half of the equation. The company was limited by the other half—programming the complex parts. While a dozen operators could perform simple programming tasks on machine controls to accommodate approximately 300 orders per month and 250 new files per year, they needed the help of CAM programmers for complex programming issues, such as when parts require the use of a CAD file or the creation of a more complex geometry.

After examining several alternatives, Lathuille-Hudry purchased Esprit from DP Technology because of its ease of use and solid references from other French contract machining companies. Daniel Frossard, CNC programming project manager, was tasked with the CAM software’s integration and optimization. After some training offered by Esprit reseller MHAC Technologies, the team quickly became proficient with the technology and started refining the post processors. “The open post processors offered by Esprit give us full control of our programming,” Mr. Frossard says, adding that Esprit’s CAM solution makes it easy to modify post processors to create the high-quality G code necessary to fully exploit the company’s machine tools.

In 2010, the company purchased two new Mori Seiki NT turn-mills for its short-run department, which were delivered with Esprit CAM software as part of a partnership between the machine tool builder and DP Technology. The new machines joined the department’s two existing NL turning centers. “The integrated licenses have been a bonus because we probably would have been obligated to purchase one or two additional licenses to change from one machine to the other,” Mr. Frossard says. According to the company, the department quickly came up to speed with the new software because it already had good knowledge of Mori Seiki turning centers. “Since we began using Esprit, we have seen substantial productivity gains in short-run production,” Mr. Frossard says.

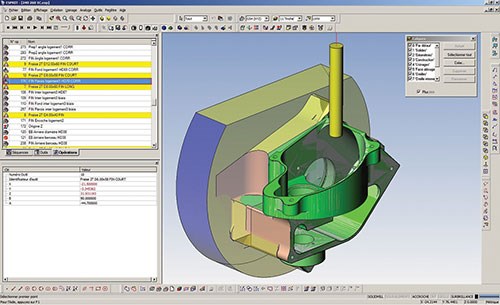

One feature that Lathuille-Hudry finds particularly beneficial is the simulation tool that is integrated into Esprit. The dynamic rendering and verification ensures that CNC programs will work as intended on the machine. “What we see on the screen is what we get on the machine,” Mr. Frossard says.

“Visual rendering is a strong point of Esprit software,” says Fabien Challamel, CNC programming methods manager.

By using Esprit CAM software, the company is able to build parts for applications such as unmanned aerial vehicles (UAVs). Other recent applications have involved producing a very sophisticated cover and a complex aerospace part on an NT model turn-mill. “We never would have been able to program these parts using traditional, manual programming,” Mr. Frossard says.

The company is seeing increasing levels of collaboration between its CAM programmers and operators, whose process expertise plays an increasingly important role in the programming process. With two licenses for C- and Y-axis turning and milling, as well as three Esprit licenses for Mori Seiki integrated into the controller, programmers can react very fast and provide operators with missing items in minimal time. Esprit makes it possible to quickly try out several machining strategies by comparing the cycle time and simulating the part geometry, thereby reducing time needed to create a production-ready program.

To improve its manufacturing and programming capabilities, Lathuille-Hudry is studying the five-axis modules delivered with the licenses, with the help of the machine tool manufacturer and MHAC Technologies. Although its customers do not require mastering these tools yet, management is planning module training to be prepared when the need arises. According to Jean-Louis Collange, MHAC account manager, the team is continually mastering complex challenges.

In fact, one of those challenges is growing its production capabilities. Management is conscious of the fact that certain machines in the workshop are producing parts that are too simple, given their capacity. “Thanks to our growing experiences in complex parts, we know what a machine coupled with a CAM tool can do,” Mr. Frossard says. “We know that we can handle projects involving more complex parts, so we are seeking out new challenges. In the long run, we are expecting complex geometries to make up the vast majority of our work on our CNC machines.”

Lathuille-Hudry is taking advantage of the flexibility offered by Esprit and is adapting it to its own methods and standards. The company has developed a unique balance between manual programming and CAM, with a few people trained on the CAM tool and a team of operators with machining expertise. Further improvements are planned in five-axis machining and machining thin-walled parts, as well as reducing machining costs across the board. According to the company, Esprit software will help them achieve these goals.

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More