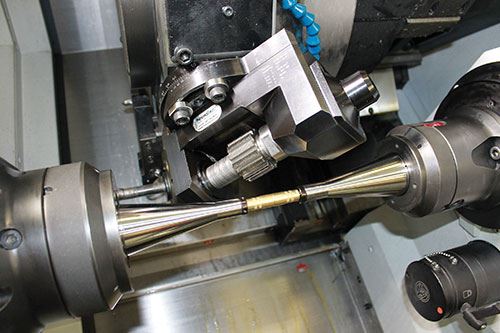

Custom Hobbing Tool Enables 45-Degree Angles

To machine helical gears at 45-degree angles, Gurecky installed a customized multifunctional machine from DMG Mori Ellison Technologies with a hobbing tool from Heimatec.

Share

As the competitive nature within a market increases, so does the need for increased productivity and throughput by handling the parts less. One way to meet this need is to accomplish more operations in one setup. Gurecky Manufacturing Services Inc. of Rosenberg, Texas, decided to enhance its manufacturing operations by purchasing a machine that could act as a regular CNC lathe and machine helical gears at the same time. However, a custom hobbing tool from Heimatec Inc. (Prospect Heights, Ill.) was necessary to achieve a desired 45-degree helix angle.

Gurecky was founded in 1983. Today, the company operates out of a 43,000-square-foot facility, serving the oil, gas and energy industries. The company produces multifaceted precision parts ranging from prototypes to mass production. To remain competitive, Gurecky constantly invests in advanced manufacturing equipment. For example, since buying its first DMU 50 ecoline from DMG Mori (Hoffman Estates, Ill.), the company has moved production from traditional vertical machining centers (VMCs) to the more versatile five-axis DMG Mori machines.

In late 2012, Gurecky President John Dorman decided it was time to purchase a CNC machine specifically for gear hobbing. The company approached DMG Mori Ellison Technologies and decided to install its customized multifunctional NLX 2500SY/700 with the ability to hob gears. What made this particular application challenging was the fact that Gurecky needed to machine helical gears at a 45-degree angle. This was a problem because standard hobbing units only allow ±30 degrees of helix angle adjustment due to loss of rigidity.

Undaunted by the task, Heimatec said it could design a custom hobbing tool with ±45 degrees of adjustment to use in conjunction with the new machine. According to Preben Hansen, president of Heimatec, lathes and their coordinating controls are more sophisticated these days, so a dedicated hobbing machine isn’t always necessary. “As long as the machines can handle it, we can build a tool to do it.”

After a few months of testing, the tool was complete and ready to be put to work. Rigidity is the key to tackling this difficult machining operation, he says. “It’s a pretty difficult operation, and when you’re twisting that tool, there’s a lot of leverage. You have to be concerned with the rigidity of the tool. When you’re turning at 45 degrees and milling at the same time, you tend to lose rigidity,” he says.

To combat this loss, Mr. Hansen says Heimatec’s hobbing units are designed with a strong bearing structure. In turn, this structure provides the rigidity necessary to reduce backlash and increase tool life. It also increases the performance of the hobs that do the cutting, he says.

The hobbing unit can run at 3,000 rpm and provide 63 Nm of torque. “One of the things we do to help is increase the torque through a gear reduction,” Mr. Hansen says. “Many times, it’s a 1:1 ratio, and we go 2:1. So if its 3,000 rpm into the tool, the tool only rotates at 1,500 rpm. So we increase the torque output by gearing down the tool.”

Heimatec and DMG Mori Ellison Technologies set up the hobbing attachment, wrote the program code and started cutting the 45-degree helical gears in a quarter of the time that it took in the past. Completing more operations in one setup has been a major time saver for Gurecky. Previously, the part would be turned on the lathe, then taken off and set up for a secondary hobbing operation. The hobbing operation alone took one to two hours. Now, the company can machine precision parts on the CNC lathe using the custom hobbing unit in 8 to 10 minutes, start to finish. Another benefit of the single setup is that scrap has been reduced from about 10 percent to 1.6 percent, greatly improving overall efficiency and the company’s bottom line.

Along with the increased adjustment angle, Heimatec designed the custom hobbing tool to be interchangeable, which enables Gurecky to use different arbor sizes. The company can put a different kind of hob in the unit and switch to a different part fairly simply. According to the company, this feature has saved more than $200,000.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More