Digital Tooling Improves Accuracy, Reduces Scrap

By switching to digital boring heads, Impact CNC was able to reduce its scrap rate while increasing precision.

Share

A scrap rate of nearly 4 percent was taking its toll on Impact CNC’s bottom line. But that wasn’t the only problem the manufacturer was experiencing using analog boring heads. Its operators were constantly checking for accuracy in fear of backlash, and it was slowing down production. After switching to digital boring heads from Big Kaiser Precision Tooling Inc. (Hoffman Estates, Illinois), the company immediately noticed a reduction in scrap as well as an improvement in accuracy.

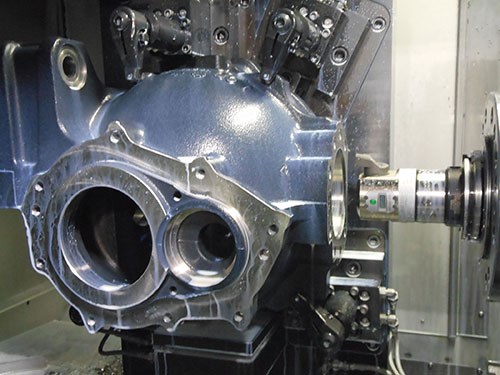

Since its inception in 2012, the Columbia City, Indiana, shop has expanded, opening its Gateway Park facility a year ago. Impact now employs 55 people and is seeking more help to fill its 30,000 square-foot operation. The contract CNC manufacturer says its mission is to meet or exceed customer requirements by providing fast, on-time delivery of specification-conforming components for the automotive, heavy truck, off-highway and oil and gas industries.

Meeting these requirements came at a high price for a 50-part batch boring application that was running at 1,000 surface feet per minute and feeding at 0.006 inch. In that particular application, which used analog boring heads, Impact was experiencing an oversized bore condition that caused a scrap rate of nearly 4 percent. The considerable waste was unacceptable, especially since the company was responsible for buying material. Moreover, the scrap rate translated into tens of thousands of dollars—possibly as much as $30,000, says Aaron Schoon, manufacturing engineer.

Though it was a major pain point for Impact, the high scrap rate was not the only disadvantage of the analog boring heads. According to Mr. Schoon, the operators were getting frustrated with the design flaws and were constantly checking for accuracy in fear of backlash. This was slowing down production.

When input adjustments don’t match the tool carrier output, the tool is exhibiting backlash oftentimes due to wear. In these cases, it’s possible that an operator might rotate the boring head’s turning dial or adjustment mark by several clicks or dial marks and still not witness any diametric movement of the cutting edge on a presetter. This is why they typically must perform time-consuming test cuts with the boring heads and make any necessary adjustments to ensure the hole is machined to its proper size rather than relying solely on an initial measurement on a presetter.

What made the process more frustrating for Impact’s operators was that although the boring heads were analog, they were anything but old. These weren’t heavily used or worn heads, rather brand new tools creating the unacceptable 4 percent scrap rate.

“We knew it was time for a change, and we moved up the brand food chain to the top in terms of reputation for quality. That’s also when we moved toward digital heads,” Mr. Schoon says. “We tested quite a few boring heads offered on the market—all digital. That seemed to be the direction the industry was moving in, so it just made sense to go digital. Operators speak digital these days.”

Mr. Schoon contacted his distributor, who in turn contacted Kelly McGaffick, Big Kaiser regional manager. Mr. Schoon had actually tested the Kaiser boring heads with Mr. McGaffick not long prior, but had opted for a different brand. However, the disappointing scrap experience with the other brand made the company reconsider, and Kaiser was invited back to perform two tests on two different digital heads.

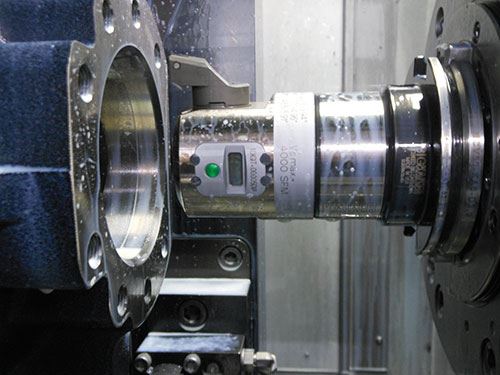

Among the higher-end models tested, Kaiser boring heads from Big Kaiser displayed the most accuracy. While the leap to digital was a perk as well as a long-term investment into forward-looking tooling, Impact’s main criteria was to find heads that had the accuracy to meet required tolerances. In addition to being digital, Mr. Schoon says the Kaiser tools had an overall better design. The direct-drive screw versus the worm gear eliminated backlash, making the product last longer, he says.

Impact employees noticed an immediate reduction in scrap with the new Kaiser boring heads. For instance, the company says that analog systems are inherently prone to human error, an effect that becomes more pronounced as dial divisions get increasingly fine. Consider an operator parsing a 0.0001-inch diameter on an analog head while splitting Vernier markings to achieve extremely precise specs. That operator is forced to juggle two separate readings in his or her mind, which can lead to a misreading, the company says.

With digital readouts, however, precision is much easier to achieve. Numerical readings are objective, not subject to interpretation.

“There was virtually no training with the new digital boring heads,” Mr. Schoon says. “They are incredibly easy to adjust. When an operator measures a bore that’s undersize, he can easily zero the boring head readout and ad-just the diameter until the digital display reads the correct diameter adjustment.”

Adjustments on a digital boring head are faster, too. Trying to make precise adjustments on diameter when counting minute dial divisions on a head takes more effort than simply glancing at a digital display—it’s an all-around simpler process.

The return on investment from digital boring comes from the time saved making adjustments on the spindle, as well as the increased adjustment accuracy, which prevents scrap and keeps the cost per part as low as possible.

Along with switching to digital boring heads, Impact also switched to Big-Plus CAT 50 holder and extensions. The new tool holders increased rigidity, helping the boring heads achieve the necessary accuracy.

Impact is still running at the same speed and feed as it did with the analog heads, only now the scrap rate on the boring operation is less than 0.5 percent, Mr. Schoon says.

“This puts us more in line with our original quotes, as we certainly don’t spec to run a 4 percent scrap rate,” he says. “If we did, we wouldn’t get any work. Between the superior design and the added suite of capabilities that the new design offers, the Kaiser digital boring heads are proving to be a huge asset to our business. We’ve seen a significant improvement to our bottom line.”

Big Kaiser’s digital boring tools are otherwise identical to their analog predecessors. With the same boring ranges, cutting parameters and through-coolant capabilities, an operator can swap an analog for a digital model with little to no reprogramming. The digital boring heads use the same accessories, such as boring bars and insert holders, as their non-digital Kaiser counterparts.

“It’s really quite simple; digital boring heads are easier to work with than analog heads,” Mr. Schoon says. “When you’re machining to tight tolerances, adjustments can be made much faster and easier than with analog heads. It’s hard to believe we haven’t been using these all along.”

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreChoosing the Right Drill Type

Specifying the right option for your application can save time and tools.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More