ERP Makes Social Distancing Possible at Make-to-Order Shops

Sponsored ContentAs we all learn to cope with the realities of the COVID-19 pandemic, the case for cloud-based ERP has never been clearer.

Share

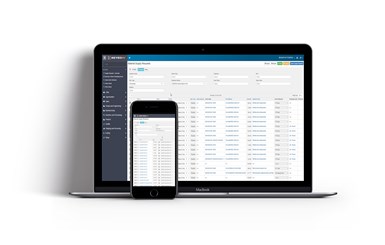

Managers using cloud-based ERP gain a complete view of their shop – from machining capacity to customer invoices – from anywhere.

Enterprise resource planning (ERP) has been around for over thirty years, and many companies have had some experience implementing a version of ERP to simplify data management. But whether you use a legacy network-based ERP system, spreadsheets or other documents, it may be worth looking at another solution. The advent of mobile devices such as tablets and smart phones has led many job shops and other make-to-order manufacturers to turn to cloud-based ERP systems. These systems enable users to update and review data from any device connected to the internet, and any data updated from one device updates information for every device, as the cloud hosts everything online.

The COVID-19 pandemic, however, makes the case for cloud-based ERP even clearer. Disruptions to work schedules, supply lines, and shipping schedules make a flexible ERP system with remote access even more valuable.

Advanced ERP Software Has Many Benefits

“One way to think about ERP,” says Nancy Brehmer, VP of Customer Experience at KeyedIn Manufacturing, “is that it captures the institutional knowledge of a shop and makes it available to all of the employees.” Say, for example, a repeat customer makes a regular order. An advanced ERP captures the CAD files, materials and operations used and can provide both management and shopfloor personnel the relevant information to complete the job, making it easier to generate quotes and convert them to sales orders without having to reenter the data.

"If KeyedIn Manufacturing hadn’t already been implemented at our sites when the pandemic hit, our company would not have been able to continue working. The system gives us 24x7 access to our sales opportunities, estimates, work orders, invoices and more, whether we’re in the office or working from home."

– Troy Schweinberg | Chief Operating Officer

Metro Sign in Oklahoma City

On top of this, advanced ERP software can provide an excellent view of the shop floor. “Managers using our system get a complete view of their shop, including resource utilization, employee availability and production capacity,” says Brehmer. “This means that a manager knows when and where they will have the capacity to handle a job, freeing up time and improving quoting.” On top of this, managers can get a clear view of material and operations, employee hours and efficiency, and accurately track on-time shipments.

The Cloud Makes It Even Better

Cloud-based ERP makes pertinent information available to everyone who needs it, including both office and shopfloor personnel.

Critically, the cloud makes all this information available remotely. “When you open our app,” Brehmer says, “you are opening a command center that provides you with all the information you need to operate, wherever you happen to be.” The ability to log into an ERP system remotely has never been more valuable. Many job shops have had outbreaks occur in-house, and no one wants to have to close down for two weeks as their employees recover. Social distancing can prevent outbreaks, but it can be difficult in cramped shops. With cloud-based ERP software, managers can monitor order progress remotely, making social distancing easier and enabling the shop to run with as few people on site as possible.

Additionally, the precise details advanced ERP systems provide a shop make scheduling jobs and people much easier, even when staggering shifts for social distancing. “In times like these, having as much information as possible is critical when planning strategies and contingencies for keeping people safe,” says Brehmer. “We make this far easier thanks to how complete a picture our system provides, as well as how accessible it is remotely.”

The Time to Upgrade is Now

Implementing changes at a machine shop is almost always difficult, and changing something as fundamental as a shop’s ERP system is bound to cause disruptions. However, the year is 2021, and every make-to-order manufacturer in North America has already been experiencing disruptions to regular business thanks to the pandemic. The disruptions affecting every stop in the supply chain ironically make this the best time to switch to a new system for many shops. “When a shop is running like clockwork, introducing change can make you stumble,” says Brehmer. “When you’ve already stumbled and work has slowed down, it makes sense to make improvements for when times get better.”

Additionally, the simple fact is that the ongoing costs of in-house ERP systems often dwarf the costs of switching to cloud-based systems. “Maintaining in-house servers and IT personnel is expensive and often less reliable than using the cloud,” says Brehmer. “And at a certain point you will be forced to upgrade anyway, because of a server that’s full, software that’s no longer being supported or something else.” Failing to upgrade your underlying business systems when the opportunity is available may mean being forced to do so – but at a much less opportune time in the future.

The security of your customer data is also a factor. Cloud-based systems are much more secure than almost any on-site system can be. “We have had customers whose business ground to a halt after a ransomware attack,” Brehmer says. “This is a major threat that KeyedIn Manufacturing avoids by storing information in the cloud.” The kind of direct cyber attacks that can paralyze on-site systems simply do not affect data saved in the cloud. This, combined with the full-time data security staff ERP vendors keep on-hand, means that a shop’s information is much more secure in a cloud-based ERP system.

COVID-19 has proven that cloud-based ERP software must be the future of the machining world. Even laying aside the improved security and complete access to shop information that ERP systems like KeyedIn Manufacturing provide, the flexibility it offers to job shops through remote access offers both a competitive advantage and an improvement to the health and safety of the people who work in your shop.