Fixturing Device Simplifies Squaring

Peter Schmidt of the Hermann Schmidt Company developed a intuitive fixture for squaring blocks for the die and mold industry. The system interfaces well with components from the System 3R catalog and is capable of making a block square within millionths of an inch.

Share

For years, machinists have squared blocks with a solid square, a vise and a knee mill. After heat treatment, block squaring is often completed on a grinder using a trusted angle square and a C clamp. Unfortunately, shops face challenges with increased offshore competition and a lack of skilled machinists capable of accurately performing this type of work. That’s why they’ve tried to develop fixtures that make the squaring process simpler and more accurate. The problem with most of these fixturing solutions is that they are complicated and don’t yield the needed accuracies.

Peter Schmidt of Hermann Schmidt Co. has developed a solution designed to overcome these challenges and take the guesswork out of block squaring. Mr. Schmidt says the solution is easy to operate and yields accurate results using machines found in the average shop. The device, called SquareTech, is produced and sold by System 3R USA Inc. (Elk Grove Village, Illinois).

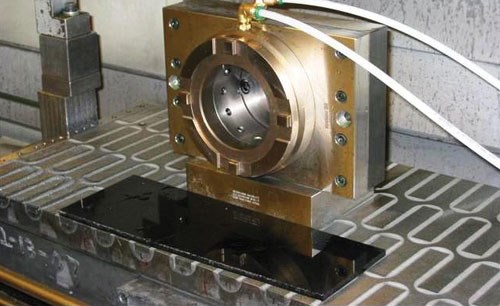

SquareTech has two primary components: a base and an indexing fixture. The base can be bolted to a mill’s T-slot table or to a flat plate for attachment to a magnetic grinding chuck. The indexing fixture has a circular profile that slides into the base. It is located and locked into the base with a precision ring around its periphery. That ring engages another ring of ball bearings located inside the base to lock precisely and rigidly regardless of the fixture’s rotation angle. The ball-bearing ring is constantly engaged via spring pressure regardless of whether the indexing fixture is present in the base or not. The indexing fixture can be removed from the base by using shop air. Air pressure applied through a control valve in the base overcomes the spring pressure. The ball bearings then recede into the base to allow the indexing fixture to spin freely.

The indexing fixture is compatible with many workpiece interfaces using components from System 3R.The SquareTech system accurately indexes parts as heavy as 200 pounds every 90 degrees. A test was recently performed at a customer site using the SquareTech system to grind a block made of D-2 tool steel. The flat grinding machine used for the test was in good condition and was located in a facility with an ambient temperature of 71° F. The part was checked with certified gages on a recently certified grade-A surface plate. In preparation for the test, the top and bottom surfaces of the block were ground parallel. The block was then attached to the indexing fixture with a standard electromagnet to provide access to the remaining four sides. Each side was ground in succession until the block had made five revolutions, with each side being ground five times. This test yielded a cube with total squareness error of less than 0.000060 inch.

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreRead Next

In It For The Long Haul

Curt Reed uses advanced grinding techniques in the pursuit of short-run, sub-micron work that other shops can’t perform or won’t attempt. His shop’s commitment to its customers is reflected in the high level of equipment sophistication and applied grinding acumen.

Read MoreOEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More