How Do You Equip a Startup Micromachining Shop?

A response to a reader’s question includes a checklist for launching a small shop focused on micromachining.

Share

A reader recently used the “Ask an Expert” feature of our Micromachining Zone to ask the following question.

Question

I am interested in getting a small machine and beginning a small business part-time from my home. With the space, power and noise restrictions in a residential area, I was wondering if micromachining would be a good option. Any thoughts and advice? What machinery would you recommend? Also, how do you pick up secondary setups on such small parts, and clamp without deformation?

Response from John Bradford, micromachining R&D team leader for Makino

Nice to receive this message. Generally speaking, from a support equipment and supplies standpoint, you will need to have the following items before you even consider the machine tool:

1. Inspection devices

Normally, there is not one specific instrument that will cover all of your measurement needs. Consider the following pieces as a necessity to get started: (1) toolmaker’s microscope or profile comparator for dimensional measurements, with magnification range 10x to 50x, and (2) stereo microscope, for part assembly and visual verification, with magnification range 5x to 25x.

2. Software

You will need a solid CAD system to perform basic design (Solidworks is great), and of course a flexible and intuitive CAM system (Mastercam is a good all-around system for 2D and some 3D work).

3. Quality tooling

This is an important point. Don't skimp on toolholders, as this provides the interface between the machine spindle and your cutting tools. If you go cheap here, you will have problems with tool wear, breakage and poor surface finish. Tooling to hold parts to the machine table is also important. We tend to recommend an integrated tooling system such as Erowa or System 3R for simple chucking and unchucking, without the need for re-setup for alignment and location.

4. Basic support equipment

Having a bandsaw and a Bridgeport-style mill are primary necessities, as you will find an ever-increasing need to produce basic fixtures, jigs and other accessories. The mill also doubles nicely as a drill press.

5. Toolmaker's tools

The pride of every toolmaker—dial indicator, micrometers, calipers, scale, sine plate and parallels are among the basics.

6. Machine tool

If you are starting off with a minimal investment, a Makino machine is overkill. Look at the Haas Office Mill. Look also at Microlution and Atometric machines, which are very small, quite flexible and will generally provide machining accuracies of 0.005 mm pretty consistently.

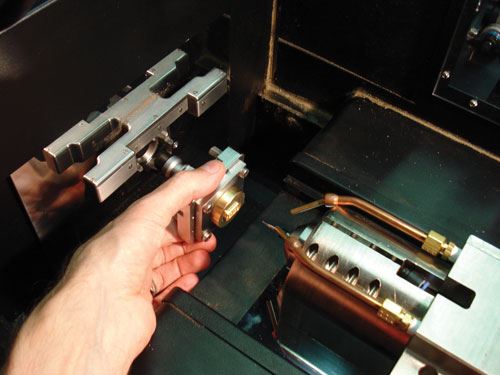

7. Part holding

My answer to your question will sound evasive, but your fixturing solution will vary as widely as the different parts you will be machining. Solutions may include Superglue, double-sided tape, epoxy, form machined flexure vises or a conventional toolmaker’s vise. This is where your experience and creativity will come in to play. There are no cookie-cutter answers to the question of holding small parts.

8. Web presence

How do you want to let the marketplace know about you? It would be wise to prepare a budget for creating an effective web site for promotion, as well as a means for your customer to contact you

9. Business plan

Take a few weeks and thoughtfully rough this out. The exercise will bring you face-to-face with the reality of what you will be entering into. (And your financier will need to have this if you wish to ask for capital!)

I hope this gives you a little more to think about. There are many things to consider: what markets to serve, how to promote yourself and what your limitations are (including time, tolerances, delivery and quantities of parts you would accept or not accept).

I wish you the best of luck to you in your potential new endeavor!

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Read MoreMC Machinery Technology Summit Showcases Manufacturing Innovations

MC Machinery Systems Inc. hosts the 2025 Technology Summit in Elk Grove Village, Illinois, featuring EDM, milling, automation and workforce strategies.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More