How to Accelerate Robotic Deburring & Automated Material Removal

Sponsored ContentPairing automation with air-driven motors that push cutting tool speeds up to 65,000 RPM with no duty cycle can dramatically improve throughput and improve finishing.

Share

As productivity and reshoring initiatives increase the demand on machine shops, automation has become necessary to patch over the holes left by the skills gap. However, meeting the production demands of a given job means more than simply attaching a robot arm to a machining cell. Automating material removal and finishing processes while achieving appropriate feeds and speeds can be daunting. It might seem like investing in a large machine tool is the only way to get the results you need.

Enter Air Turbine Tools®, whose patented high-speed pneumatic motors maintain spindle speeds of 25,000-65,000 RPM, empowering manufactures to improve their material removal processes in automated cells.

Automate Using Air-Powered Motors

Air Turbine Motors® and grinders are robust rotary tools for automated and robotic deburring, milling, drilling and grinding applications. They can operate 24/7 at constant speeds of 25,000 – 65,000 RPM and up to 1.40 horsepower (1.04 kilowatts) with no duty cycle. The company’s patented governor maintains consistent high speed and torque on the tool path at higher RPMs. This makes the motor mount series perfect for robotic milling or drilling in materials such as metals, plastics, ceramics and composites, both roughing and finishing. Negligible vibration and low weight also make this motor mount series ideal for end of arm robot mounting and automation.

In addition to maintaining these high speeds, Air Turbine Motors’ low friction turbine drives have just two moving parts:

- Proprietary governed turbines

- Air-cooled steel bearings

As a result, this motor generates no heat and experiences no thermal expansion, as proven in third-party testing. With only two moving parts, there is less wear, making them highly durable. Contrast with electric, vane and geared motors, which all generate friction and heat. Additionally, the Air Turbine Motors require no maintenance, no oil or other lubrication. These factors combine to make them perfect for automated machining.

In heavily automated machining cells, one of the most important factors is consistency, which these motors provide. With air motors generating so little heat, they make excellent components of automated cells, as they operate with no duty cycle and almost no thermal growth.

This reliability combines well with constant high spindle speed maintained in cut to dramatically accelerate production while reducing costs. Additionally, the high peripheral speed results in improved cutting action, cleaner finish and longer cutting tool life.

These motors are perfect for automated and robotic deburring, contouring, profiling, drilling, polishing, engraving, de-flashing, routing and milling in hard and soft materials such as metals, plastics, wood, ceramics and composites.

Easy Set up and Mounting

Air Turbine Motors mounted series incorporates heavy-duty bearings within a rigid stainless-steel housing that is easily mounted. The low vibration production and low weight make them ideal for mounting on a robotic end effector or in a fixture. The lack of electrical components make them easy to install. Just connect 90 psi (6.2 bar) air line of dry clean air and you are ready for 24/7 production.

450XHD Motor Case Study

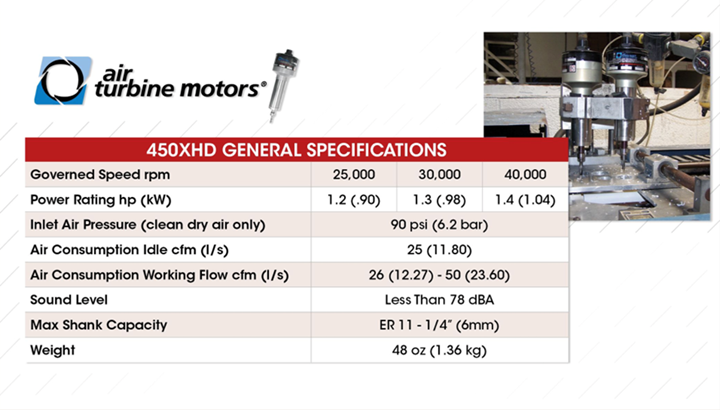

See below for a video case study of Air Turbine Tools® 450XHD motor and specification sheet.

The powerful 450XHD’s double front ceramic bearings assure durability in 24-hour operations. The 450XHD’s sealed front-end prevents wet or dust contamination from getting inside the motor. This patented double turbine motor operates at governed speeds of 25,000, 30,000, or 40,000 RPM, with power to 1.4 HP (1.04 kW). Ideal for routing composites, plastics or wood and deburring, finishing or drilling metal at constant high speed. The rigid 41 mm O.D. steel barrel is easily fixtured for automation or combined with a robot end effector.

450XHD Air Turbine Motor® Specification Sheet

The 450XHD is one of many Air Turbine Motors. A wide variety of diameters, speeds and power ratings are available for integration. Please visit Air Turbine Tools to learn more about the wide range of economical High Speed Air Turbine Motors® available.