Share

On one hand, Alexandria Industries’ first attempt at machine-tending robotics was Rosie. On the other, it was not so rosy.

“Rosie” is the name the aluminum extruder, machining and fabricating company picked for its first machine-tending robot. Installed in one of its Alexandria, Minnesota facilities in 2001, the cell this robot was to anchor was designed for a family of parts for the telecommunications industry. The cell included two CNC machine tools; two conveyors that would feed Rosie fresh workpieces to load into the machines; a camera to enable her to locate workpieces on the conveyors to pick, eliminating the need and cost for hard fixturing; and an area where she would deliver completed parts to awaiting pallets.

However, a downturn in the telecommunications industry caused the company to lose the work for which the machining cell was created before production ensued. As a result, there was a significant need to redeploy the cell, one that was no small investment.

Eventually, the company came up with a strategy it hoped would help the cell investment return: It identified an existing repeating job—extruded aluminum housings for oxygen delivery systems—that also featured a family of like parts. The idea was to dedicate that job to one of the cell’s conveyors and machines, and then work in other jobs to keep the remaining conveyor and machine (and Rosie) busy.

Capacity and CNC Robotics Manager Todd Carlson admits that this strategy did not work so well. When one machine was down for a new-job setup, maintenance or other reasons, the robot and second machine also had to be shut down because shopfloor employees needed to enter the cell to safely perform their tasks. With this configuration, the cell never delivered the production efficiencies the company hoped for.

“We thought we’d never try our hand at robotic automation for CNC machining again,” Mr. Carlson says.

After struggling with it for a couple of years, Alexandria Industries decided to simplify the cell. It removed one of the machines and dedicated the cell to the family of oxygen-delivery-system housings. In making this change, spindle uptime and production output for the cell’s sole machine increased by more than 30 percent. Mr. Carlson says it was at that point that the company realized simplifying and standardizing its approach to automation could help it realize more of unattended machining’s potential benefits.

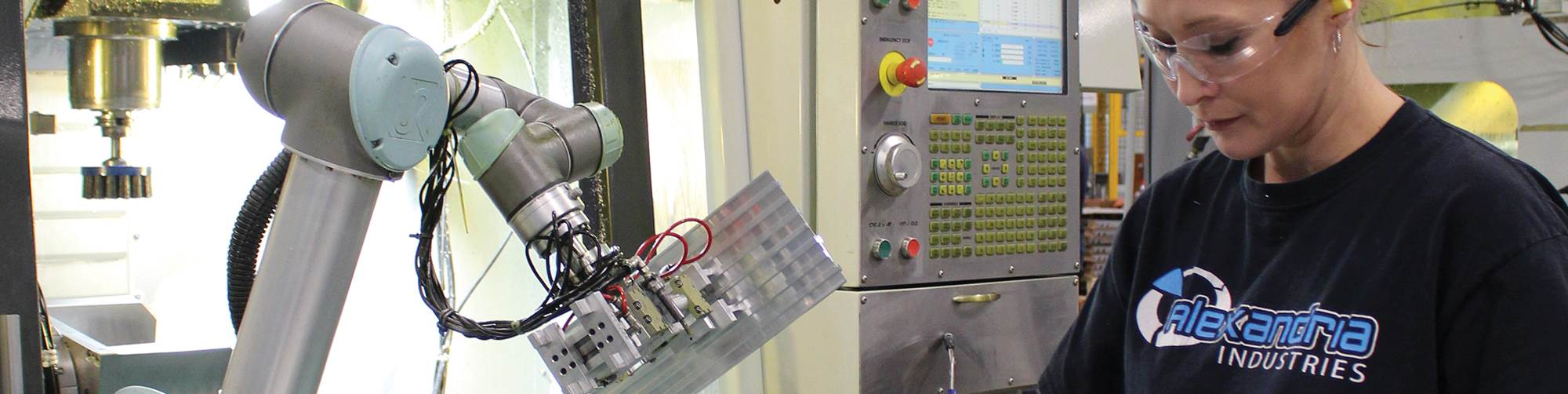

Alexandria Industries has since applied that thinking to the design of various robot-tended machining cells. In fact, the company now has more than 20 robots in this facility, some of which are collaborative models (aka “cobots”) that feature force-sensing technology so that employees can safely work alongside them to measure, deburr or package components. (For example, if a cobot unexpectedly contacted a person or object, it would recognize that and stop moving before injury or damage occurred.)

All its robot-tended machining cells are designed to accommodate numerous jobs, as many as 50 in some cases. When designing these cells, concessions had to be made in terms of production speed and flexibility. Still, traditional job shops thinking about adding machine-tending robots are well-served to consider Alexandria Industries’ strategy of setting up cells to succeed in a high-mix/low-volume part-machining environment.

Keep it Simple, Standardize

Alexandria Industries was founded as Alexandria Extrusion Company in 1966. Its 188,000-square-foot facility located in the city that shares its name features a range of manufacturing capabilities. There, it extrudes and machines 30 million pounds of 6000-series aluminum alloys per year, much of which undergoes additional machining, fabrication and other value-adding operations. (The company has another location in Alexandria as well as facilities in Wheaton, Minnesota; Indianapolis, Indiana; and Carrolton, Texas.)

The raw material used at this facility is delivered in 20-foot-long bars—either 3.5 or 7 inches in diameter—that the company refers to as “logs”. This facility has two 7-inch extrusion presses and one 3.5-inch press. (The Indianapolis facility has a 10-inch press.) Prior to extrusion, the logs are sawn into 18 to 28-inch billets. Each section is then brushed to remove any oxide coating from its surface and delivered to an induction heater that heats it to as much as 850° F in a mere 75 seconds. The extrusion press pushes the soft, heated aluminum through a die to create the desired profile. This Alexandria facility extrudes approximately 3,500 components and has approximately 5,500 dies (some of which are copies). After cooling, the extrusions are sawn to length, and many require some machining work.

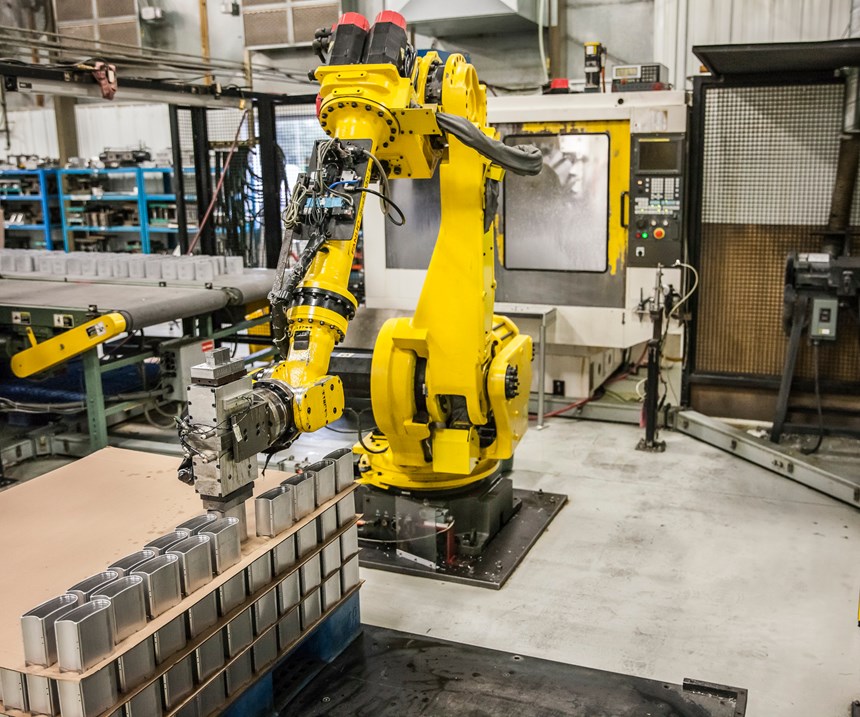

After dialing in its first robot-tended machining cell, the company decided to give automation another go by standardizing the process. In 2005, it installed two cells with infeed and outfeed parts conveyors, FANUC LR Mate robots and Haas VF2 vertical machining centers (VMCs) with fourth-axis rotary indexers. These were integrated by the company’s machine tool distributor, Productivity Inc. Like Rosie, the robots in these cells also used cameras to locate parts to be picked from the infeed conveyor.

Alexandria Industries’ goal with these cells was to run a mix of parts with maximum lengths of 8 inches. “We looked for repeating jobs in which parts were similar in size and shape, and required somewhat straightforward machining work,” Mr. Carlson explains. “We wanted to establish a family of like parts for each cell instead of trying to accommodate any and all jobs. We didn’t want to run complex parts unattended in the cells. Those jobs we’d rather run on standalone machines with an operator standing by to perform part inspection, monitor tool wear and, in general, keep an eye on the process.”

Within six months of installation, the two cells were running 24/7 at full capacity, machining as many as 30 different jobs. The company added two more identical cells, and those were soon running at full capacity, too. Today, it has six VF2 cells, and one operator can tend three cells at a time. Standardizing on equipment and process makes it easy for operators to comfortably tend any of those cells, Mr. Carlson notes.

Alexandria Industries also standardized its workholding strategy for the robot-tended machining cells. Initially thinking it would use the fourth-axis indexers only for parts that required machining on multiple sides, the company removed the indexers from the machines when they were not needed and replaced them with hydraulically actuated vises. However, the company discovered that it made more sense keeping indexers mounted in the machines and making fixtures for the indexers for parts that required machining on only one side. By maintaining that same indexer location, the company would not have to tweak robot programs because the indexer was not re-installed at precisely the same position as before. It justified the added cost for indexer fixturing because this strategy sped and simplified change-overs. Mr. Carlson says it could take two hours to reinstall an indexer and modify the robot program.

That said, the reason the company limited the cells to parts no longer than 8 inches is because of how the parts were loaded into the machines. In order to enable operators to access a machine’s CNC and door, a side window was installed through which the robot would load and unload parts. As a result, the robot could not extend a part longer than 8 inches through the window and maneuver it to the fixture.

Despite these limitations, the company wanted to automate the machining of longer parts. It initially created a cell with infeed and outfeed conveyors around a bigger Haas VF6 VMC with five-axis trunnion table that could accommodate parts as long as 24 inches. Eventually, it replaced that with a Haas UMC 750 five-axis machine. It now has three UMC 750s in identical cells with safety fencing that enables operators to access the machines’ CNCs.

Looking to automate the machining of parts as long as 50 inches, Alexandria Industries created six similar cells around Haas VF6 VMCs with fourth-axis rotary indexers. At first, an operator could tend only one cell at a time largely because of the size of the parts and the manual deburring and washing operations they required.

With the VF2 cells, operators could grab a number of parts and place them in a vibratory tumbler to deburr them, and then wash them prior to packaging. That is why one operator could tend multiple machines. Given the longer parts that run through the VF6 cells, operators could manually deburr and wash only one part at a time, meaning they could only keep up with one cell at a time. As a result, robotic deburring and part-washing capabilities were added to each VF6 cell, enabling one operator to tend two cells.

Alexandria Industries has since turned to collaborative robot technology to enable VF2 VMCs to machine parts ranging in length from 8 to 24 inches. Because of the collaborative nature of these robots and appropriate risk assessment and mitigation, the cobots can be positioned in front of the machines to load parts through the machines’ doors (instead of a smaller side window) while operators perform other duties in the same vicinity.

Robots and People Getting Along

The company purchased its first cobot, a UR5 model from Universal Robots, four years ago. These robots use sensors to detect when they unexpectedly contact something (or someone) as they move through their programmed path. Alexandria Industries now has four VF2 cobot cells that one person can tend while performing duties such as in-process inspection and packaging.

Mr. Carlson says this robot technology is a good example of the trade-offs a machine shop might have to consider when deciding which configuration of robotic cell makes the most sense for their business. For instance, the UR5 models have a maximum payload capacity (including end effector) of 11 pounds. Conventional industrial robots have higher payload capacities, but this is not an issue because the cobots at Alexandria Industries are handling relatively light, aluminum workpieces. The cobots also move at a slower speed than industrial robots for safety purposes because they are not operating alone in a secure work area that people cannot access during operation.

However, a low price point makes cobots attractive. Company manufacturing engineers integrated the cobots themselves, eliminating the cost of an outside integrator. Operators have found that programming the cobots from the touchscreen control pendant is intuitive and relatively easy.

Cobots can also be redeployed to tend other machines or perform other duties. In fact, the base designed for the cobots includes forklift pockets that would enable them to be easily moved throughout the shop. That said, each time the company added a cobot cell, that cell would quickly reach maximum capacity, so it did not make sense to redeploy the cobots. However, its most recently purchased cobot is currently not assigned to any machining cell. The base for that cobot also includes forklift pockets as well as wheels to enable it to be moved through the shop. The company is currently working to identify non-machine-tending applications for it, such as deburring, riveting, assembly and simple tapping.

Automation’s Affect

Mr. Carlson says production employees were initially leery of the robots, thinking they might eventually take away jobs. However, automating the repetitive, monotonous task of loading and unloading machines has enabled the employees to grow their technical skills and focus more on problem solving. He believes that it also has helped the company retain some of its best talent. In fact, robotic automation makes the company more enticing to potential new hires who see they won’t be performing basic manual labor all day long.

“The robots have really helped grow the company’s sales,” Mr. Carlson says. “We’ve actually had to add employees since we started adding robots due to that growth.”

And while Rosie has officially retired, her robotic successors look forward to long lives working next to the company’s 625 employees.

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAddressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More