July 2018 Product Spotlight: Grinding

This month’s Modern Equipment Review Spotlight focuses on various grinding machines and equipment for all sorts of applications.

Share

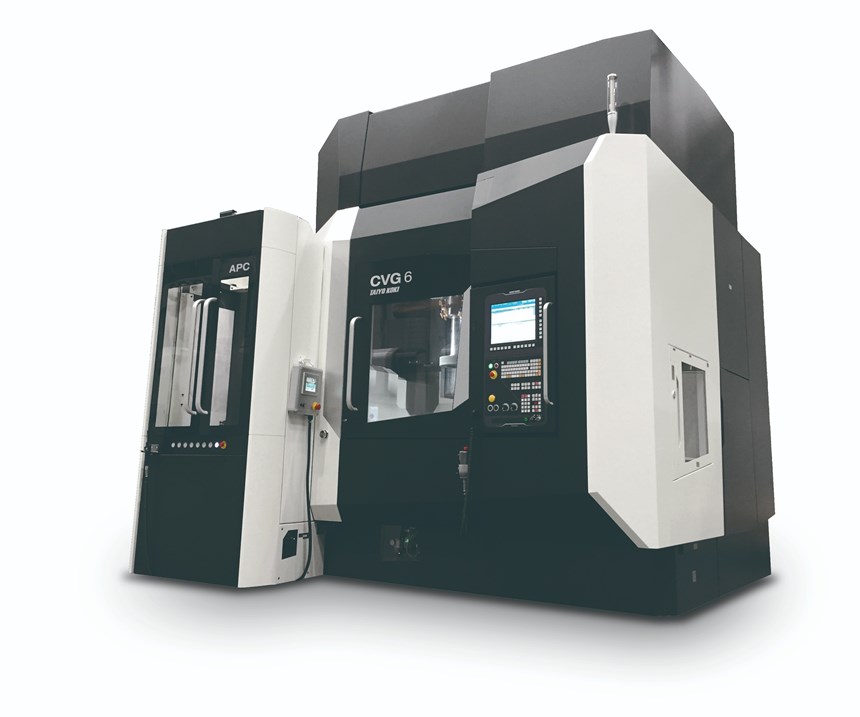

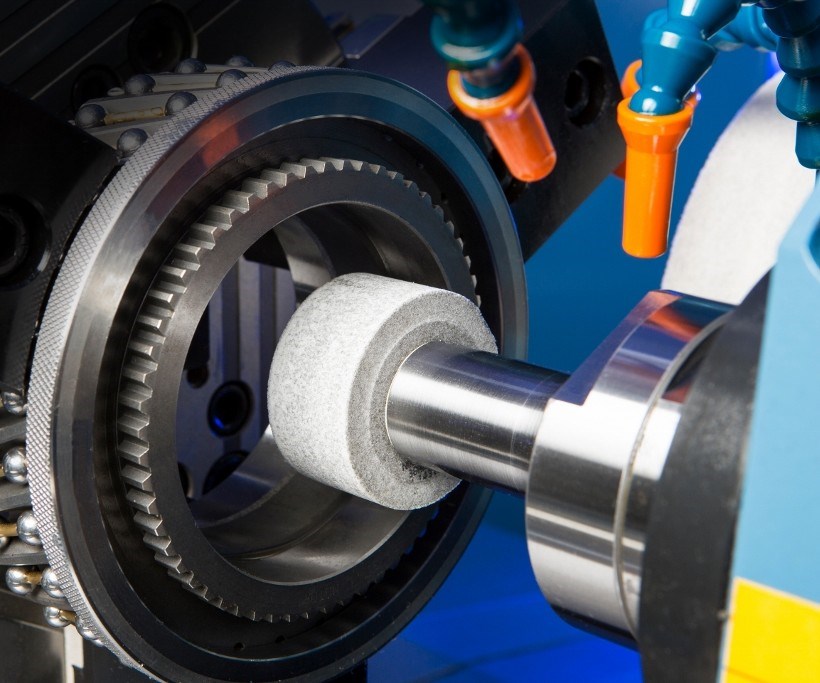

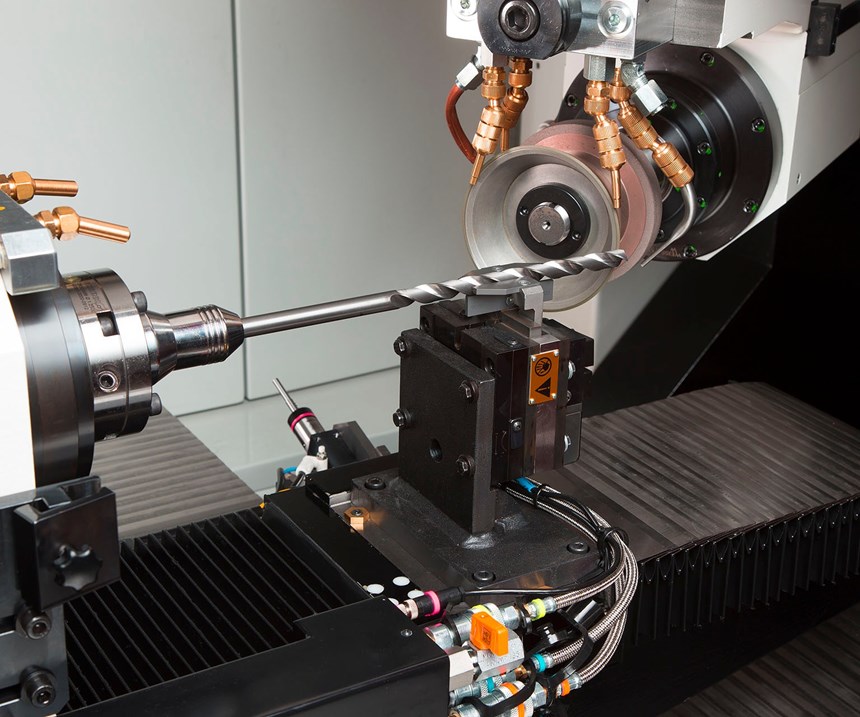

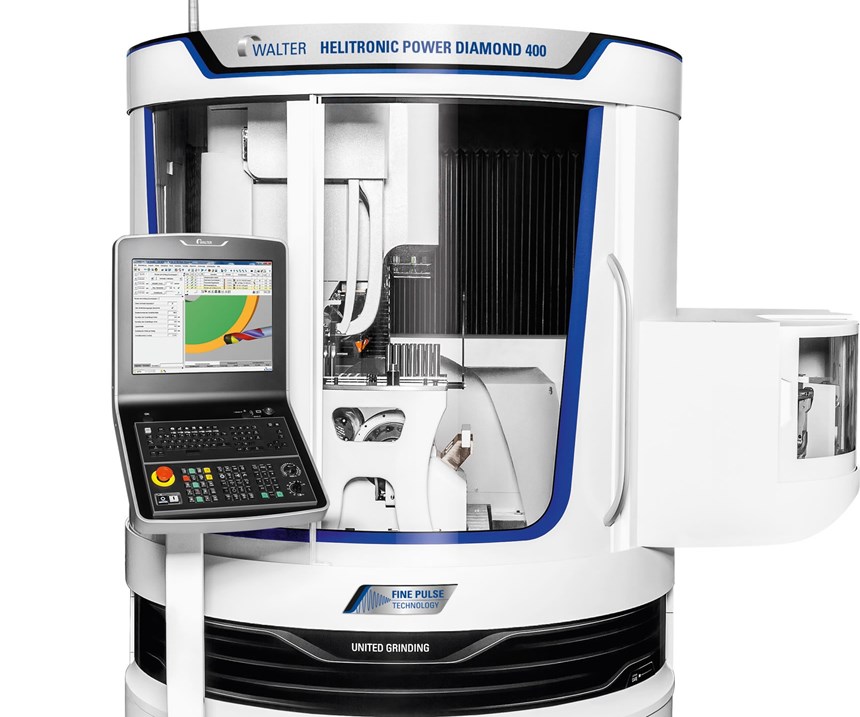

The image gallery above, based on Modern Machine Shop magazine’s Modern Equipment Review Spotlight, features a variety of grinding machines and related equipment from DMG MORI (Taiyo Koki), Holroyd Precision, Innovative Products of America, Erwin Junker, Lach Diamond, Star Cutter and United Grinding.

Swipe through the gallery for details, and follow the caption links for more information about each item.

Related Content

-

Automation is for Everyone

Not just for large shops, automation can help even the smallest shops solve labor challenges and become more profitable and efficient.

-

Additive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.