New Band Saw Cuts Production Time

By upgrading its equipment to Danobat band saws from Pat Mooney, Masterform Tool Co. was able to increase production, decrease vibration and save money.

Share

Common advice says that you shouldn’t fix something that isn’t broken, yet Masterform Tool Co. (Franklin Park, Ill.) knew that if it wanted to improve productivity, it needed to upgrade its band saws. By installing a new band saw on the shop floor, the company was able to eliminate its older machines and maximize efficiency.

Founded more than a century ago as a tool and die company, today Masterform specializes in the manufacture of end caps and heads for the air and hydraulic industry. After 20 years of relying on the same brand of saws to cut stainless steel, aluminum and 1117 bars, the company decided it was time to update. At first, Masterform considered replacing its existing saws with newer versions from the same builder; however, the saw technology had not improved much in two decades. Masterform was also displeased with the fact that the saws were manufactured overseas.

In search of a better solution, owner Richard Perales visited the International Manufacturing Technology Show (IMTS) in Chicago, Ill. in 2012. At the booth of Addison, Ill.-based Pat Mooney, he discovered Danobat high-production band saws and decided to incorporate the new technology on Masterform’s shop floor. The saw and its system were installed in half a day, and the Danobat was making parts the same afternoon. In fact, Pat Mooney needed only 10 minutes to show the company how to use the new band saw.

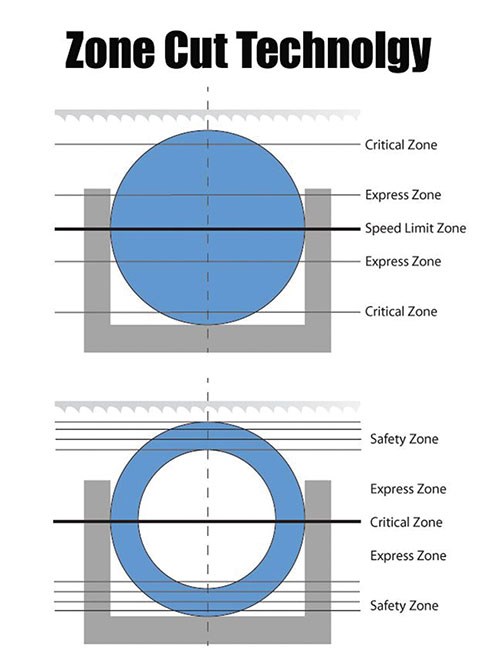

The saws are equipped with a Zone Cutting System to maximize productivity. This system brings CNC control to cutting operations and increases the number of parts that can be produced per shift. The technology works through automatic selection of speed and feed based on material. One of the benefits of the new band saw was that Masterform employees no longer needed to direct blade movement by hand.

The Danobat DS 3A horizontal fully automatic band saw machine, which Masterform runs 18 hours a day, and the Pat Mooney Nishijimax CNC carbide cutoff system have replaced all five of Masterform’s former band saws.

“The Danobat is very technically advanced, but so easy to operate,” Mr. Parales says. The operator presses a button to change from stainless steel to steel or stainless steel with aluminum. “Just clean out the chips and go,” he says. Danobat’s automatic operation has also resulted in less vibration and noise, he says.

Masterform’s productivity has significantly increased with the installation of the Danobat saw. “The Danobat can literally handle twice what the old saws were doing, and get it out in half the time, Mr. Perales says. In the end, Masterform is getting a better-cut part, more productivity and more profitability at the end of the day, he says.

For a cylinder customer, Masterform regularly cuts 80 bars made of 316 stainless steel measuring 2 by 10 5/8-inches. In the past, the company could saw one bar at a time at most and process it in 4 to 5 days. Today, the manufacturer cuts two of the same bars, and if there are four or five bars in that project, they complete processing within a day and a half.

While Masterform expected to increase production using the Danobat saw, it did not foresee the savings in saw blade costs. Using the original five saws, Masterform was spending $500 per month in saw blades. In four or five months, the company has maybe spent $1,000 on blades with the Danobat, and it has three or four blades on the shelf right now, Mr. Perales says. Because the Zone Cutting System enables standardization of the cutting process, it achieves maximum blade life.

Masterform was also interested in improving tolerances. The DS 3A is accurate as it is efficient. To ensure a precision cut part, the DS 3A includes a movable arm that is automatically adjusted to the width of the material and is in the optimum position in relation to the moving vice. This ensures that the band saw blade is supported as near as possible to the material on both sides of the cut. The main round column and the secondary prismatic column are designed to accept high blade tensions. The material is clamped on both sides of the blade, thereby reducing burrs on the cut component.

Using the Danobat, Masterform overcame further limitations of its old saw. According to Mr. Perales, the indexer wouldn’t index 22 inches long; however, the company can now stock from 3/8 by 2 inches to 14 7/8 inches in multiples of 22-inches long.

.png;maxWidth=300;quality=90)