Preventive Maintenance Via iPad

GTI Spindle Technology’s VibePro system enables users to monitor vibrations, temperature, velocity and other critical machine information.

Share

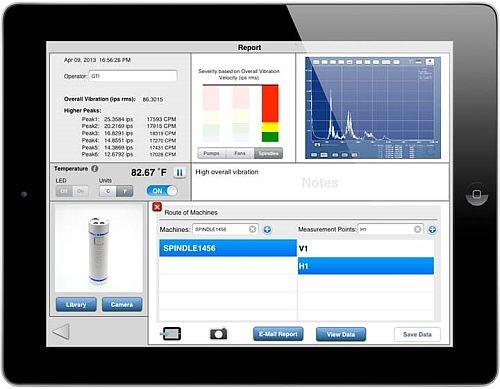

Users of GTI’s VibePro system can monitor, record and analyze data directly on iPad devices.

Headquartered in Manchester, New Hampshire, GTI Spindle Technology provides spindle products, repairs and services for a range of industries including aerospace, defense, medical and more. The company, however, doesn’t just fix broken spindles or sell new ones—it hopes to help shops avoid broken equipment altogether with its VibePro preventive maintenance system that operates through the iPad and iPad Mini. VibePro 6, the most recent iteration, was released in November and is optimized for use with iOS 7 and Apple’s new iPad Air.

The system combines iPad hardware with GTI’s software and various accessories to monitor and analyze indicators including vibrations, balance and more. For example, the Bluetooth-enabled Node Therma sensor records temperatures ranging from -94°F to +716°F within its 15-foot measuring zone, and sends the data wirelessly to the iPad for analysis. Users can view machine data on the iPad itself, or access the information in the cloud via a free web app.

Visit GTI’s website or check out the VibePro 6 Overview video on YouTube for more on this system.

Related Content

-

Five-Axis Machines Speed NASCAR Engine Production

Moving from an aging set of five-axis mills to more advanced machines enabled Hendrick Motorsports to dramatically improve its engine production.

-

Milltronics Five-Axis Machining Center, Control Enhance Productivity

Milltronics USA Inc. introduces its first five-axis machining center, the VM250IL-5X, as well as its machine control, the Inspire+.

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

.jpg;width=70;height=70;mode=crop)

(1).png;maxWidth=300;quality=90)