Providing Consistent Tool Engagement in Five Axes

BobCAD-CAM says it is the first to provide a consistent tool-engagement-angle toolpath strategy for two through five-axis operations.

Share

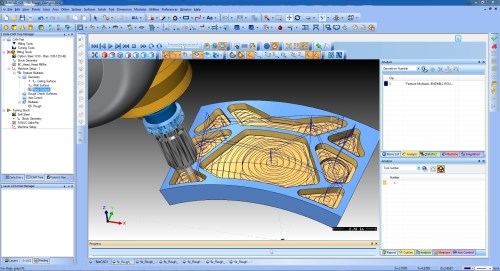

The Adaptive Roughing consistent-tool-engagement-angle tool path is well-suited for features such as this pocket that follows the contour of a cylinder.

BobCAD-CAM is a software developer that has offered affordable, intuitive CAM packages for two- and three-axis machining applications for nearly 30 years. The company recently released its new Version 25 four- and five-axis mill software packages that enable it to offer a single programming platform for an increasing base of customers that are integrating higher-end equipment.

One way users can benefit from these packages is the ability to perform four- and five-axis simultaneous roughing operations. In fact, a new multi-axis tool path available in the company’s four-and five-axis packages makes such simultaneous, multi-axis roughing routines even more efficient. Adaptive Roughing applies the concept of consistent tool engagement angle that previously has been available only for two- and three-axis operations to four- and five-axis simultaneous movements. The company says it is the first to provide a consistent tool-engagement-angle toolpath strategy for two through five-axis operations.

Related Content

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

Legacy After Loss: Writing the Next Chapter of a Family-Owned Machine Shop

When a beloved machinist’s passing left his shop in his children’s hands, the three siblings stepped up, transforming the business to honor his legacy and build a new future.

-

Shop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.