The Right Mix Of Tooling And Machines Streamlines Process

When people talk about car performance, they often neglect to consider the influence of tires. Yet tires can impact fuel efficiency by as much as 10 percent. As manufacturers strive to improve tire performance, tread patterns tend to become more complicated.

Share

When people talk about car performance, they often neglect to consider the influence of tires. Yet tires can impact fuel efficiency by as much as 10 percent. As manufacturers strive to improve tire performance, tread patterns tend to become more complicated. In addition to the increasing complexity of tire-mold manufacturing, the industry’s current trend of outsourcing work can make it difficult for companies to remain competitive. Like others in the industry, Chris Sipe, president of Northeast Tire Mold, believes that investing in technology is the best way to deal with these challenges.

Northeast Tire Mold is a supplier to a number of OEM tire manufacturers. In 1976, Mr. Sipe’s father founded the Akron, Ohio shop with only an air compressor and a few small tools. Today, the company has 12 CNC machines devoted solely to tire-mold production. During a typical year, Northeast produces about 500 different molds for passenger cars, motorcycles, trucks, race cars and aircraft.

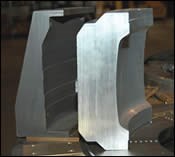

A couple of years ago, Mr. Sipe decided to invest in equipment that would enable the shop to move away from the typical casting process and machine treads directly into the molds. Machined molds are more precise than cast molds, which require clean-up and deburring, the company says. In addition, the machined molds are made in segments, each with eight to 12 treads and separate sidewalls. This type of design enables the company to re-machine problem components individually instead of recasting the entire mold. All in all, the new technique enables the company to get products to market faster than the casting process.

The company realized that it would need to invest in new equipment to make the move to direct machining. While attending EMO in Hanover, Germany, Mr. Snipe was intrigued by Alzmetall machines, which he felt were appropriate for the company’s applications. Before making an investment, however, he assembled a team consisting of Northeast employees and outside suppliers. The goal was to find ways to maximize the machine’s performance to address the shop’s needs.

One member of this team was Dave Ivory, technical specialist at Seco Tools Inc. “We showed Mr. Ivory the parts that we wanted to make so he could then analyze the machine—the horsepower, the spindle speed, the coolant pressure, and so on” Mr. Sipe explains. “This meant that we could put together a tooling package that would optimize the machine’s capabilities.”

Northeast says its faith in Seco was based on a long-standing 12-year relationship. “We started working with Seco when we added our first turning center,” says Mike Christie, Northeast vice president. “We continued to do business with the company because it offers great service. Seco stays by our side until the tool is up and running right. Consequently, it's the only carbide supplier we use for turning, milling or drilling.”

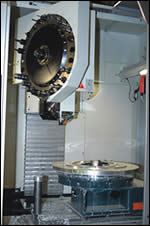

After the team completed its analysis, Northeast purchased a five-axis Alzmetall machine for cutting the treads. Later, the company invested in a four-axis Alzmetall machine to manufacture special containers that hold the mold pieces together for the curing process. Northeast says Seco’s custom tooling package helped achieve substantial productivity gains once the container work moved to the four-axis machine.

Each container is machined from a flame-cut sheet of 1020 steel that resembles a giant flat donut or washer. The containers are built to various sizes, some with ODs as large as 60 inches. First, the giant washers are roughed on a Defum three-axis turning center with an indexable Seco turning insert. “The flame-cut area leaves a jagged edge, so we have to turn the OD to a specific diameter,” Mr. Christie says. “Although this is tough on the tool, we machine to within 0.001 inch of finish dimensions.”

Next, the containers go to the Alzmetall four-axis for hole machining. A typical container top has so many holes and notches that it resembles “a piece of Swiss cheese,” Mr. Ivory says. The most time consuming part of the container-machining process is the creation of nine 3-inch-wide, 2-inch-deep pockets around the diameter of the workpiece. The previous machine took six hours to machine the holes with a 2-inch plunge mill. However, with its higher horsepower and Seco R217.20 high-feed milling tool, the new machine cut plunging time to 34 minutes. Within an hour, the company was running the tool at 42 hp and 7,200 rpm—its maximum capability.

According to Mr. Sipe, the research team’s advance planning played an important role in the company’s ability to get the new process up and running so quickly. “What amazes me is that many immediately recognize the value in investing in a new piece of equipment; however, they may fail to realize the significance of investing in quality tooling,” Mr. Sipe says. “Labor hours on the machine represent the biggest expense, so the actual tooling costs are not as crucial dollar-wise. Taking the labor hours out of the process is what counts.”

After the plunging process, the container undergoes a variety of drilling operations. First, the company runs Seco’s feedMax solid carbide drill at 7,500 rpm and 53 ipm to machine 72 holes to the required depth. Then, each 0.257-inch-diameter hole is thread-milled with Seco’s solid carbide Threadmaster.

Next, CrownLoc drills machine 46 holes ranging in size from 1/2 inch to 7/8 inch. The exchangeable crowns on the drill allow feeds as high as 21 ipm, thereby reducing machining costs. This process creates holes that are precise enough to finish with thread milling, the company says. Finally, four large holes are machined with indexable Perfomax drills, which can handle heavy metal removal.

“A critical issue in drilling that is often ignored by people is that you must have both sufficient coolant pressure and volume, and this is dependant upon the through-coolant holes in the drills,” Mr. Christie says. “As the holes get larger, the pressure needn’t be that high, but you still need the volume. We’re running at 800 psi and 12 gallons per minute, but this increases as the size of the hole in the drill gets smaller.”

The company says it can now produce four parts per day, compared with only one part using the old method. The biggest time savings involved the plunging operation, which Northeast says is 19 times faster. Mr. Sipe says the company emphasizes quality over quantity and aspires to machine difficult, extremely technical molds.

“Our investment in technology is key,” Mr. Sipe says. “We want the best machine tool and everything that goes with it—the foundation, the holders and the collets. We consider Seco a critical part of this technology team.”

Related Content

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More