There Are Apps For That, Too

These two iPhone apps provide manufacturing professionals and students with quick access to helpful cutting tool information directly from their smart phones.

It was bound to happen, and Jim Rowe is one of the first to do it. The “it” is the development of Apple iPhone applications (or “apps”) to assist machinists, programmers and engineers with the cutting tool calculations they commonly perform.

Mr. Rowe is product developer of Smart Calculations (smartcalculations.com). The two affordable iPhone apps he developed—the Machinist APPrentice and the Machinist Journeyman—are based on his 30-plus years of experience with cutting tool use, selection and instruction. They provide manufacturing professionals and students with quick access to helpful cutting tool information directly from their smart phones.

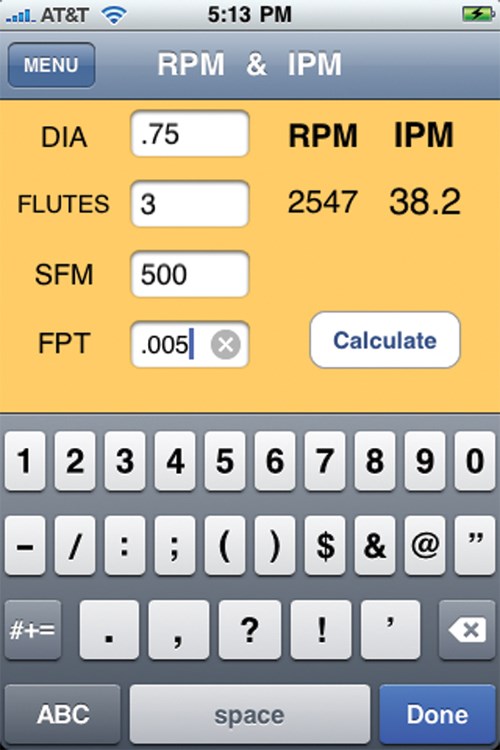

The Machinist APPrentice, the first app Mr. Rowe developed, is available for download from Apple’s Web site for only $2.99. The app, which features a clean, uncluttered layout, offers basic conversion functions and performs cutting tool calculations for a variety of machining operations. Its main menu allows users to choose from four sections: milling, turning, references and math/conversions. The image to the right shows the portion of the milling section for determining cutting speed and feed rate given the tool diameter, number of flutes, surface feet per minute and feed per tooth. The Machinist APPrentice can also calculate threading helix angle, tap feed, tap drill diameter, drill point length and more.

The new Machinist Journeyman app (available for $9.99) offers expanded content in addition to advanced calculations geared toward increasing cutting efficiency. For instance, a variety of chip thinning factors can be calculated for radial width of cut, ballnose depth of cut and 45-degree cutter lead angles. In addition, the Machinist Journeyman app can create line-by-line G code for thread milling operations. Its lathe section focuses heavily on threading and its conversions and reference sections include a selection of trig programs. Mr. Rowe plans to update this app to include toroidial depth of cut calculations, carbide grade information and Geometric Dimensioning and Tolerancing (GD&T) reference materials. He also plans to make both apps available for use with Blackberry and Android phones.

Video: Machining App Examples

This online video shows how chip thinning factors can be calculated for radial width of cut and ballnose depth of cut using The Machinist Journeyman app. The video also demonstrates how the app automatically generates G code for a thread milling application.

Related Content

-

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. Derek Korn, Production Machining’s editor in chief, shares suggestions from a CNC machine shop.

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

.jpg;width=70;height=70;mode=crop)