Tooling Up for Vertical Turning

Before adding its first CNC vertical turning lathe, this manufacturer researched cutting tools to determine which would complement the process and also be most effective on the parts and materials to be machined.

Share

Depending on the size and shape of the part being machined—larger, cylindrical pieces in particular—CNC vertical turning lathes (VTL) offer certain advantages over horizontal turning centers. With a VTL, gravity pulling down on the part means less clamping is required to hold the workpiece in place, resulting in faster, easier setups. Plus, cutting forces are directed straight down into the machine base, which helps the tool cut more aggressively, achieving increased material removal. To get the most use out of a VTL, however, it is important to choose the right cutting tool for the part and material it will machine.

That’s the lesson West Point Industries learned when it decided to incorporate vertical turning into its production line in 2013 to accommodate larger workpieces. Although the company had years of experience with horizontal turning, it realized that the larger pieces the VTL would enable it to machine would require the tool to remain in the cut much longer than it does on the smaller parts traditionally turned on horizontal lathes, and so different tooling would probably be required.

“We’d been thinking about buying a VTL for quite some time,” says Pate Huguley, president, “so when a contract that justified it came along, we decided to go ahead and make the investment. But we did a lot of research on the best machine for our application before the order was placed, and as we got ramped up we also worked with our suppliers to learn about the right cutting tools to use. We wanted to make sure that the machine and the tools matched so that we’d get the best performance out of both and the best results in terms of the finished part as well.”

Strategic Decisions

Founded in West Point, Georgia, in 1868, the company was primarily associated with the textile industry for more than 100 years. When that work began disappearing in the late 1990s due to offshoring, it was a serious blow, and one that required a fundamental restructuring of the company’s profile moving forward. The primary lesson learned had to do with market diversification, and with so many textile jobs being sent overseas, it became important for the company to both seek out new markets and distribute jobs more evenly among customers. With the company’s activities grouped into four operating units—Defense Systems, Industrial Division, Contract Services and Industrial Supply—it began a careful evaluation of its equipment and capabilities.

Basically a job shop, West Point’s Industrial Division provides services such as turning, milling, drilling and boring. It is fed by the company’s on-site green sand cast and ductile iron foundry, which produces some 100,000 pounds of iron each week for internal use and also ships castings to customers that choose to handle their own machining. As streamlining progressed, the company began selling off older machines in order to make way for newer technologies that would make it a more attractive partner to its customers.

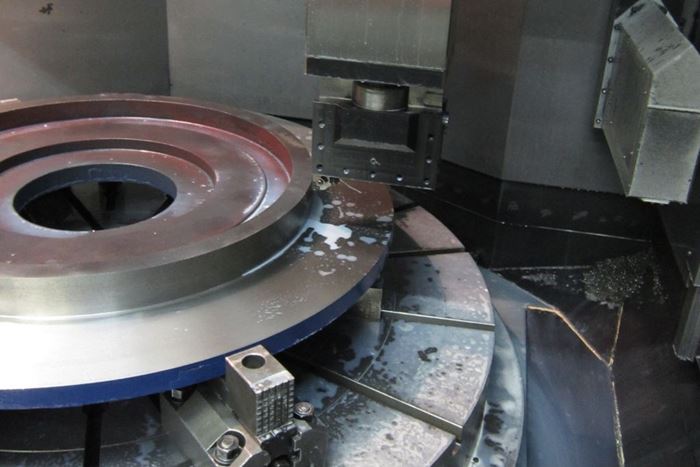

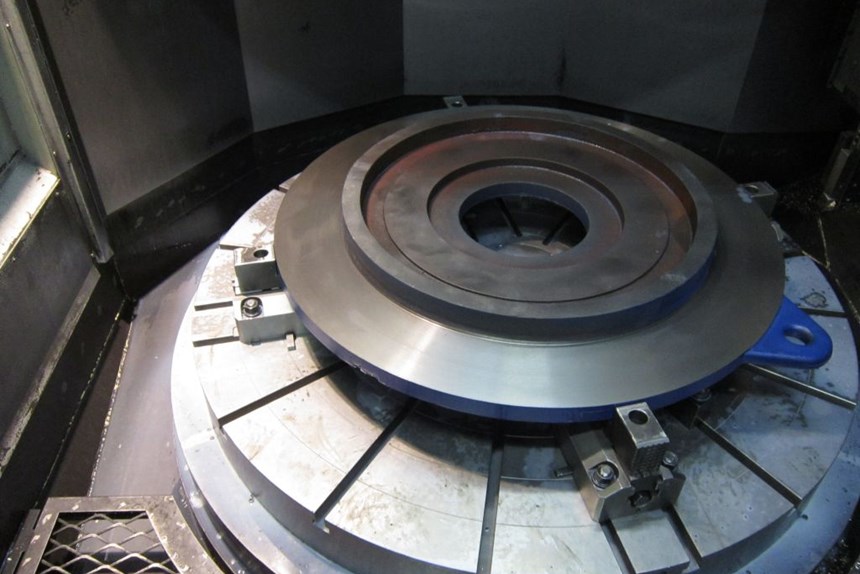

Approximately two years ago, a new contract provided the opportunity the company had been waiting for. Since it involved machining a much larger part than West Point was accustomed to working with, the manufacturer knew it was time to move up to vertical turning. General Manager Gary Jones called his long-time supplier Rick Coleman of C&S Machine Tools in Atlanta, who encouraged him to take a look at the Yama Seiki GV-1600 VTL. After identifying end users in Texas and Iowa who had purchased the same model, Jones made site visits to discuss their experience firsthand. What he learned convinced him that the Yama Seiki machine would meet his company’s current needs, and then some.

“Having such a large VTL that could accommodate castings weighing as much as 17,600 pounds and parts as big as 70.8 inches in diameter fit in perfectly with our strategic plans,” Mr. Huguley says. “And with new capabilities to offer, we’d be able to go after business that we couldn’t have before.”

Testing the Tooling

Mr. Jones recalls obtaining valuable information during the two site visits he made, and believes that any company considering introducing a new machining process into its production line should first see the machines in action and speak with their operators. For instance, one of the companies he visited suggested choosing gear-driven rather than belt-driven designs, convinced they’re more reliable. The other actually provided West Point with postprocessors for MasterCAM software to output NC code to the GV-1600. Some of the most important lessons Mr. Jones learned, however, occurred right on West Point’s shop floor.

The parts to be cut for the new contracts that spurred the addition of the VTL were made of different materials, one being white iron provided by the customer and the other gray iron poured in West Point’s foundry. Mr. Jones knew these two operations would require separate tooling, so he began researching what was available through his primary tooling vendor, John Marth of MSC Direct in Atlanta.

“We determined that they’d need a specialized insert for the white-iron job, since that material is so hard and brittle,” Mr. Marth says. “Not only does white iron push 60 HRc, it’s also very abrasive. It even has a bit of scale because it was sand cast, so the initial pass acted like an interrupted cut. We tried standard carbide grades to begin with, but even top-grade carbides weren’t holding up well, so we decided to go with a Kitzel RNG-43 CBN indexable insert. Even though it’s more costly, it works well with this material and provides a lot of cutting edge.

“For the gray-iron job, which was a much larger part, we wanted to find an insert that wasn’t too specialized so that it could be used on different projects,” he says. “It also needed to be able to handle the 50 horsepower the Yama Seiki delivers along with its low rpm, which allows you to make deeper cuts.”

In this case, Mr. Marth reached out to Bryan Stusak, application engineer for the Southeastern U.S. region with Seco Tools, who made a site visit to observe West Point’s specific application and advise the company on the proper tool choice. “We tested our CNMG 543-M6 TP0500 turning insert on their shop floor,” Mr. Stusak says, “and the combination of its grade and chip breaker really worked well for them.”

According to Mr. Stusak, TP0500 is a good choice for larger parts such as the one West Point wanted to turn because it features Seco’s Duratomic coating technology, which is designed to provide increased tool life, speed capability and edge toughness. “This grade is for long in-cut times or where large amounts of metal need to be removed, and it is ideal for harder ISO P steels in the 33 to 40 HRc range, where general-purpose grades deform,” he says. “It’s also great for P05 and P10 application areas and for use in ISO K materials such as ductile iron, even when the cut is slightly to moderately interrupted. Due to TP0500’s coating thickness and substrate composition, it will hold tight tolerances with fewer offsets.”

As for the insert’s M6 chip breaker, introduced in 2013, “It has a wide working window in the ISO P materials group, featuring a strong positive land and rake design that helps curl and break the chip efficiently,” Mr. Stusak says. “The relatively low cutting forces of this design contribute to less power consumption, a reduction in cutting forces and extended tool wear. This chip breaker design enables higher feed rates, which ultimately produces higher output for the end user.”

Throughout this search for the appropriate tooling for this particular job, Mr. Jones and Shon Wingo, West Point’s CAM programmer, were basically looking for an insert that provided a combination of wear resistance—bigger parts mean longer cuts and extended contact between the insert and the workpiece—and the ability to perform the interrupted cuts commonly found with some castings. Once that decision had been made, and with the machines installed and the proper tooling in place, it was time for West Point to begin exploring its new capabilities.

Powerful Results

While uniformly positive, the experience of each person who comes into contact with West Point’s Yama Seiki GV-1600 VTL differs slightly, depending on his perspective. As general manager, Mr. Jones is happy to have found tooling that enables the company to get everything it can out of its new machine. “You can buy a powerful machining center,” he says, “but if it’s not equipped with the right cutting tools then it’s not going to live up to your expectations.”

Mr. Wingo was initially concerned about the learning curve associated with shifting from programming a horizontal to a vertical lathe. As it turns out, he hasn’t experienced any problems with making the change. “All you’re doing is taking a horizontal workpiece and standing it on its end,” he says. “So once you’ve gotten that straight in your mind, there’s really nothing hard about it if you’re already an experienced programmer.”

Anthony Taylor, the machine’s operator, is probably the West Point employee most impressed with the VTL, since he’s in a position to witness the increased rigidity and resulting rise in material removal firsthand. He has also found that what he’s learned turning large-diameter parts on the VTL has already led to streamlined setups in other operations, including horizontal machining. “Since the weight of a vertical workpiece helps hold it in place, you can look at your workholding differently and use less of it,” he says. “It’s also pretty amazing how much this machine has reduced cycle times.”

And Mr. Huguley has enjoyed planning a future for the company that is bolstered by a machine that few job shops in his area possess. “Whether we’re approaching a new or an existing customer, you can tell they understand that having a VTL this powerful is a real game-changer,” he says. “I really think that Gary and Shon approached it the right way, by doing the research to make sure we were making the right decision every step along the way. The fact that we’re getting such a good return on our investment is proof that they helped us to do that.”

Lessons Learned

Asked if he would approach this project any differently in retrospect, Mr. Jones has a few suggestions for others who might find themselves in the same position. “First of all, go visit somebody who’s already using the machine you’re thinking about buying, and make a point of talking to the guy who’s actually running it, because nobody knows more about it than he does,” he says.

“Secondly, when your cutting tool supplier asks you to try a new insert, try it. It’s tough to stay on top of all the new tool designs, so it’s great to have an expert you can call to help you with tool selection,” he says. He also suggests that companies allow the tooling supplier to demonstrate how the insert works, not just describe it.

Finally, he reminds companies to take into account that there are many different factors that must be considered when matching up a machining process with a cutting tool, such as speeds and feeds, workpiece shape and material, how much power the equipment delivers, and the very characteristics that the machine’s design provides. “When it comes to results, vertical turning really does outperform horizontal turning for the right workpiece,” Mr. Jones says, adding that the experience has been so positive they’re considering a smaller VTL with live tooling to enable turning, milling and drilling on the same machine.

“If you’ll do your best to make sure that your machine is outfitted with the proper tooling before you make that first cut,” he says, “you’ll find that it definitely pays off in the long run

West Point Industries, call 706-643-2483 or visit westpoint.com. Yama Seiki, call 909-628-5568 or visit yamaseiki.com. Seco Tools, call 248-528-5200 or visit secotools.com. MSC Direct, call 800-645-7270 or visit mscdirect.com.

Read Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More