Eastern Kentucky Opens CNC Educational Center

The East Kentucky Advanced Manufacturing Institute, in partnership with Haas Automation and Advanced Robotics for Manufacturing, hopes to provide advanced job training to Eastern Kentucky residents.

The small town of Paintsville, Kentucky, has partnered with Haas Automation and Advanced Robotics for Manufacturing (ARM) to open the East Kentucky Advanced Manufacturing Institute (EKAMI), a job training and educational facility for teaching the knowledge and skills needed to use CNC machining centers. The February 20th grand opening ceremony, which featured speeches and technology displays, was attended by more than 200 people. The event celebrated the inaugural class, which is already three quarters of the way through its 16-week curriculum.

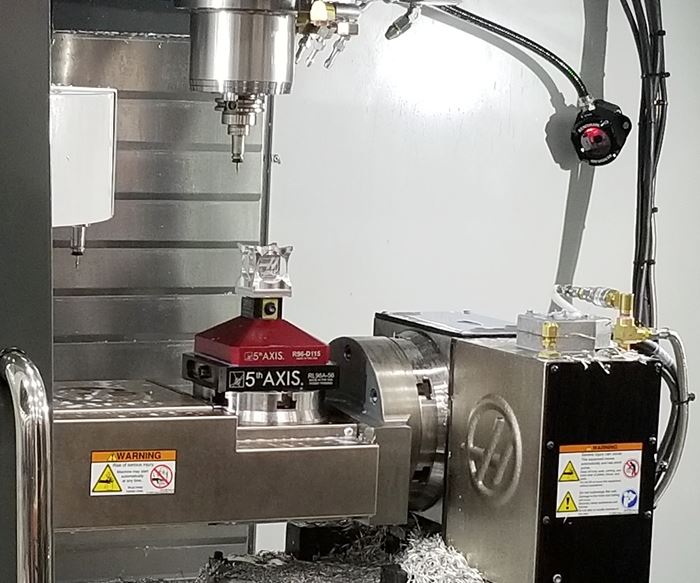

The students had the opportunity to demonstrate what they are learning, such as machining lower-arm parts for racing vehicles. Ranging in age from 18 to 55, the students began their curriculum with classroom instruction. After learning the fundamentals of machining, they receive basic experience on a manual machine center before moving to CNC vertical machine centers (VMCs) and ending with CNC turning centers. The institute exclusively uses Haas machine tools, including both three- and five-axis VMCs.

Speakers at the event included Director Kathy Walker, Judge Tucker Daniel, Governor Matt Bevin and Gene Haas, founder and CEO of Haas Automation. Ms. Walker, who spearheaded the project, spoke of the effort it took to make it happen, from lobbying state and local officials to finding and renovating a building already owned by the state. She envisions the center as a place where former coal miners and their children can learn skills that will make them valuable additions to the manufacturing workforce. “This is about diversifying the region’s economy and finding sustainable answers,” she said. “It’s about taking our hard-working Appalachian workforce and preparing them for the jobs of tomorrow.”

According to the Appalachian Regional Commission, the poverty rate in Appalachia is consistently higher than the national average, a problem exacerbated by the decline in coal mining in the region. In Appalachian Kentucky, the poverty rate is 25.4 percent, and the sparsity of good-paying jobs in the region perpetuates this trend. Ms. Walker and others who have helped get EKAMI off the ground hope to create a strong manufacturing presence in the region, attracting jobs through the availability of skilled workers. Judge Daniel and Governor Bevin both expressed hope regarding Ms. Walker’s goals.

Mr. Haas spoke about the state of North American manufacturing, saying that the United States has to fight hard to maintain its market share. According to him, education and training are key to being competitive, and the EKAMI group is part of that effort. His company has implemented a training and education initiative for CNC manufacturers around the world called Haas Technical Educational Centers (HTEC). Designed to expand the United State’s manufacturing base, the initiative promotes the education of students in high-tech machining and manufacturing at more than 1,800 schools and universities, with at least one in every U.S. state. The company provides its CNC machines and control panels for the learning process.

Related Content

-

Inverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

-

3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.