Five-Axis Front and Center at Hurco's 50th-Anniversary Event

Machine tool builder Hurco had its five-axis technology on display, and provided attendees with a sneak peek at two other machining center models that will be introduced at this year's International Manufacturing Technology Show.

Putting five-axis machines front and center, machine tool builder Hurco opened the doors of its Indianapolis, Indiana, headquarters last month to celebrate the company’s 50-year anniversary. Hurco marked this event by giving tours of its facility and demonstrating the capabilities of its machine tools, including sneak peeks at two new models that will be introduced at the International Manufacturing Technology Show (IMTS). The open house event also featured music, a speech by Indianapolis Mayor Joe Hogsett, an appearance by National Hot Rod Association racer John Force, and a presentation about five-axis machining strategies by Hurco Product Technical Specialist and author Mike Cope.

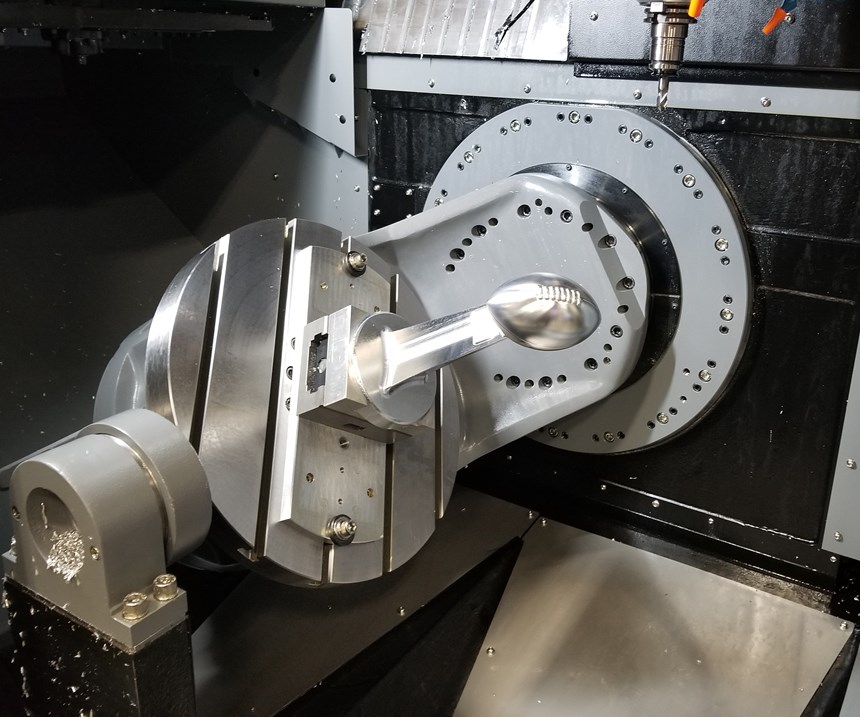

Hurco prominently displayed five-axis vertical machining centers (VMCs) during the event, including the VC500i, a trunnion-style machining center capable of full-five-axis machining. The machine can handle workpieces as heavy as 550 pounds with a work area of 520 by 450 by 400 mm. It has a solid iron frame for increased stability, and the table rotates in the B axis 110 degrees in either direction for machining hard-to-reach areas. With a 30-tool automatic tool changer magazine, the VC500i can perform numerous complex operations in a single setup. On display was a smooth, aluminum replica of the Lombardi trophy milled on that very machine.

Hurco has a reputation for emphasizing the advantages of five-axis machining be it 3 + 2 positioning or full-five-axis contouring. In addition to offering training sessions for five-axis machining, it maintains a website with information about five-axis machining that features articles and training videos. The company’s own Mike Cope, author of The Power of Five: The Definitive Guide to 5-Axis Machining, gave a presentation on five-axis machining, which he believes will be the future of the industry thanks to its versatility and time savings.

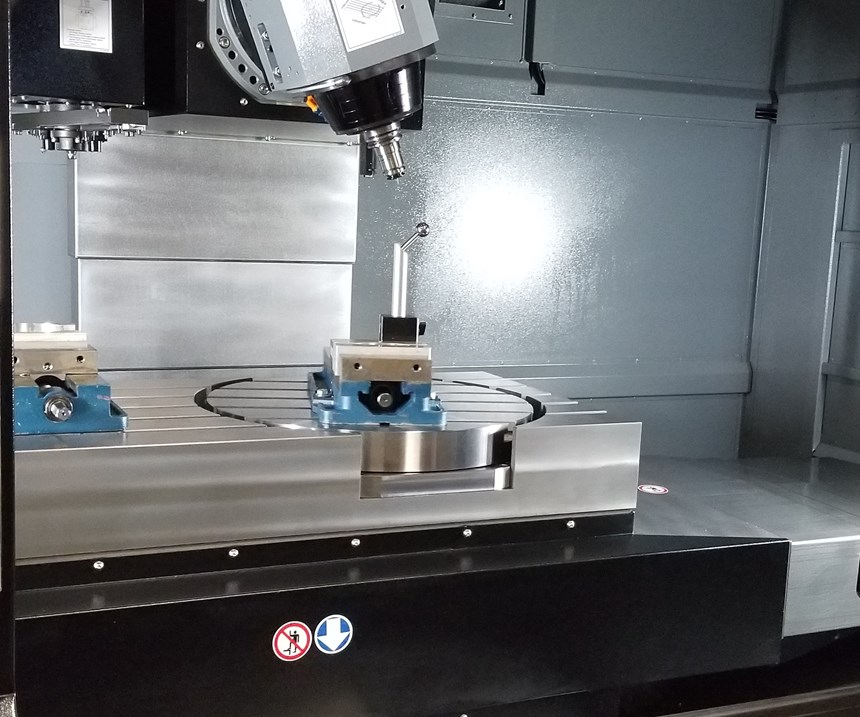

Another five-axis machine, the VMX42SRTi, offered flexibility as its chief draw. The machine includes a C-axis rotary table mounted inside of and flush with the larger rectangular table that moves in the X and Y axes. The swivel-head spindle rotates in the B axis in addition to moving along the Z axis. Users can clamp a workpiece into a vise on the rotary table for five-axis machining, then flip the part to finish the sixth side in a vise on the other side of the table. Furthermore, users can remove all vises to machine larger parts in three axes or perform both three-axis and five-axis runs on two separate parts fixtured on the machine.

The company also displayed machining centers outside its five-axis offerings, including two new models that will be introduced at IMTS. These included the HTL series turning center, a machine that can be programmed via CNC or operated manually. It is designed for toolroom work, but also functions as a stepping-stone into CNC machining. The Bx50i is a dual-column, bridge-type VMC designed with mold making in mind. It has a large workzone, and its size and rigidity enable it to perform effectively at high speeds. Having a maximum spindle speed of 18,000 rpm, the machine is capable of attaining tight tolerances and quality surface finishes on large workpieces such as mold cores and cavities.

In addition to the machining technology on display, Hurco also took attendees through its training center, which it offers to help customers learn about its machines, as well as to teach techniques and concepts to machinists. The educational center has classroom space and a suite of CNC simulators. A class on five-axis machining presented by Mr. Cope was underway as my tour group passed by. The company says it is dedicated to exploring teaching opportunities to familiarize both current and would-be manufacturers with the technology that drives the industry.

With 50 years of manufacturing capital equipment under its belt, Hurco had plenty of cause to celebrate. As long as it continues to produce quality machine tools and support future manufacturers, it should look forward to decades of success in its future, too.

Related Content

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Read MoreModern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

Read MoreQuick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)