Video: HEM Versus Conventional Machining

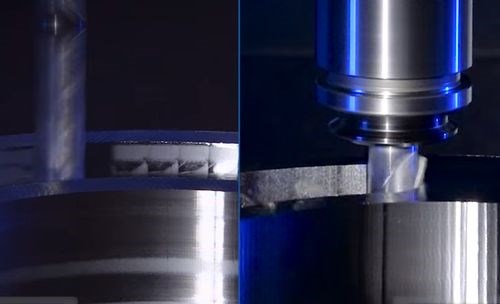

A short video illustrates the differences between conventional machining with multiple shallow passes versus high-efficiency machining with a tool designed for deeper cuts.

Share

High-efficiency machining (as opposed to say, high-speed machining) aims to reduce overall cycle time with a more efficient cutting process. This means taking fewer cuts at higher torque and deeper depths—often the full length of the flute—to clear material as efficiently as possible. To compensate for the larger axial depth of cut and avoid overloading the machine or tool, HEM relies on strategies such as a smaller radial depth of cut and different cutting patterns than conventional machining.

The right cutting tool can help, too. At EMO this year, IMCO Carbide introduced two series of tools designed specifically for high-efficiency machining. The Pow-R-Path IPT and IPC series have a larger diameter core to help avoid breakage in continuous cuts as deep as 4.5×D. Both 7- and 9-flute tools are offered. To aid in chip removal, the cutting tools are available with IMCO’s Chip Management System (CMS), which leverages a series of small notches on the cutting edges to break chips into shorter pieces that are easier to remove from the cutting area with coolant or an air blast. When paired with HEM tool paths, the series tools can run at higher feed rates and reduce overall cycle times.

The video above demonstrates how this works, showing a 1/2" IPT7 mill using a HEM strategy compared to a 1/2" four-flute mill using a more conventional method with multiple cutting passes.

Related Content

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Shop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

- B.jpg;maxWidth=970;quality=90)