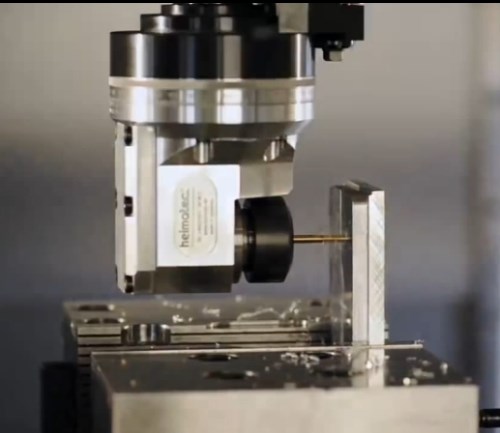

Video: Installing a Right Angle Head on a Toolchanger

This video steps you through the process for installing a standard right-angle head on a machine’s tool changer.

Share

Angle heads enable machine tools to perform milling, drilling and tapping operations in areas where a machine’s standard spindle can’t access. But how do you set up an angle head to work with a machine’s automatic toolchanger? Heimatec, manufacturer of live tools, angle heads and multi-spindle drill heads, takes you through the process for a standard right angle head in the video above.

Related Content

-

Choosing the Right Drill Type

Specifying the right option for your application can save time and tools.

-

Eight Articles to Understand Live Tooling

A roundup of the most read articles about live tooling on Modern Machine Shop.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

.png;maxWidth=728;quality=90)

.jpg;maxWidth=300;quality=90)