Columns

IMTS 2022 Review: Attention to Automation Extends Beyond the Robot and the Machine

The advance toward increasingly automated machining can be seen in the ways tooling, workholding, gaging and integration all support unattended production. This is the area of innovation I found most compelling at the recent International Manufacturing Technology Show.

Read MoreExamining Productivity Gains Set to Transform Additive Manufacturing

Additive manufacturing is in its second hype cycle, with companies weighing its endless design capabilities against cost and production output.

Read MoreBuilding a Better Business: Lessons for Machine Shops From an Unexpected Source

Learning how to be a great manufacturer by listening to the insights of a different industry, homebuilding (which perhaps is not so different after all).

Read MoreSecuring Processes for Automation

Securing a process for reliable automation takes much consideration, but many modern machines have features that can help.

Read MoreHow Additive Manufacturing Could Reach its Next 'Plateau of Productivity'

Integrated digital production set to transform additive manufacturing.

Read MoreHow Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

Read More5 Tips for Getting the Most From the Historic Return of North America’s Biggest Manufacturing Event

Plan. Explore. Think of the future. And oh yeah, the shoes. Here is how to get the most from the major manufacturing event that none of us have experienced in four years, and that many will be experiencing for the first time.

Read MoreSensitive and Strong: Advanced Digital Comparators

Borrowing from cell phone touchscreen technology, user interfaces on industrial gages are increasingly sensitive — and strong.

Read MoreSolving Holemaking Issues: Boring or Reaming?

Single-point boring and reaming are both excellent ways to meet high tolerances and finish requirements for hole making, but each has distinct specialties.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

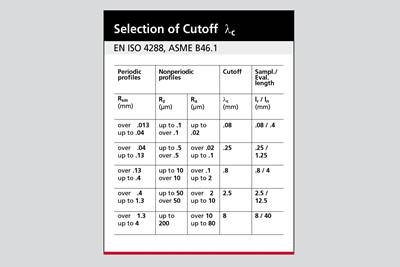

Read MoreHow to Choose the Right Cut Off When Measuring Roughness

Measurement results for surface finishing parameters can vary depending on the filter parameter (Lc), also known as the cutoff.

Read MoreHow Manufacturing Data Can Save the World

Digital spaces rooted in real-world sensor data help scale big ideas and move humanity toward a more sustainable, autonomous future.

Read More

.png;maxWidth=300;quality=90)