Esprit CAM Software Integrates with Mazak's Smooth AI CNC

This development is an outgrowth of a collaborative partnership between DP Technology and Mazak Japan.

Share

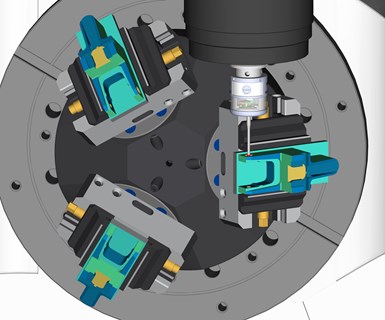

Esprit by DP Technology has announced extended support for Mazak’s Smooth AI CNC. Esprit produces optimized G-code programs, performs program optimization and provides machine simulation for Mazak’s entire line of machine tools. This extended support for Mazak’s Smooth AI CNCs now includes the ability to use Esprit’s digital twin capabilities from within the CNC. This development is an outgrowth of a collaborative partnership between DP Technology and Mazak Japan.

With this extended support, Esprit project data is thus synchronized with the Smooth AI CNC. The synchronized project data includes the part and stock models, workholding, tooling, work offsets, tool offsets and G-code program. With the synchronization between ESPRIT CAM and Mazak Smooth Ai, users can now preview the entire machining process virtually on the CNC — using the ESPRIT digital twin — before executing the program on the machine. As a result, manual data input is eliminated, and the machine operator is offered greater assurance of the machining process, the company says.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

-

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.