Star Cutter Receives Grant for Employee Training

The Going Pro funds assist employers in training, developing and retaining current and recently hired employees.

Share

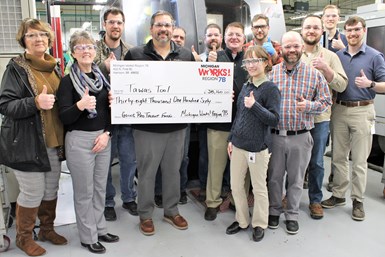

Star Cutter announces that its Tawas Tool, Ossineke Industries and H.B. Carbide facilities have received 2023 Going Pro Talent Funds from the Department of Labor and Economic Opportunity-Workforce Development (LEO-WD) through the Michigan Works! agency. The Going Pro funding source assists employers in training, developing and retaining current and newly hired employees. Past statistics from employees trained through the program indicate a retention rate of over 80%.

“The Going Pro grant funding is an excellent opportunity for Star Cutter to invest in training for our most important assets, our employees,” says Lindsey Bielby, human resources manager. “The funds provided cover a wide range of our training needs as we continue to develop our employees’ skill sets and career paths.”

Tawas Tool Company, a designer and manufacturer of gear tools, is using the funds to provide education through 18 different online courses at the Michigan Manufacturing Technology Center (MMTC), where it will become certified in everything from ISO 9001 Auditing to Blue Print Reading to Introduction to Collaborative Robotics. Additionally, selected employees will attend classes in electrical studies and industrial safety at Alpena Community College.

At Ossineke Industries, Star Cutter’s deep hole drills manufacturing location, funds will be used to provide Solidworks CAD Program training to two employees, as well as sending four employees to classes at the MMTC in ISO 9001: 2015 Internal Auditor, 8-D Problem Solving and Core Tools training. Additionally, Ossineke plans to hire two new team members, and these funds will enable them to receive six weeks of cross-training on different plant responsibilities

At the H.B. Carbide facility, where the company manufactures tungsten carbide blanks and preforms, the funding is being used to provide training to two new team leaders in the areas of Lean Office Practitioner, Lean Manufacturing Practitioner and Lean Single Method Exchange of Die, SMED.

In addition to the training being provided through the Going Pro funding, Star Cutter runs apprentice programs and ongoing training for its employees.

Related Content

-

How I Made It: Matt Erbach

One of only 10 teachers statewide to receive the 2025 Golden Apple Award, Matt Erbach earned the honor for his exceptional work teaching CNC machining and welding — a rare recognition for a career and technical educator. In this interview, Erbach shares how he transformed a neglected shop class into a cutting-edge manufacturing lab.

-

Shop Tour Video: You've Never Seen a Manufacturing Facility Like This

Explore Marathon Precision’s multi-process approach to manufacturing, where blacksmiths and hand-forged dies meet state-of-the-art CNC machining. Discover how restoring classic muscle cars and building custom art projects creates a dynamic shop culture — and draws top talent to this unique and innovative metalworking facility.

-

Lessons That Matter for the Future of Automated Job Shops

The Automated Shop Conference (TASC, August 12–13) is designed for job shop leaders looking to implement automation in practical, high-impact ways — from lights-out machining to AI-driven programming and front-office integration. Here are 10 standout sessions led by shop owners, engineers and innovators who are pushing automation forward without massive budgets or unrealistic expectations.