Verisurf, Open X Partnership Furthers Metrology Education

Verisurf Software has partnered with the Open X education platform to provide online courses on dimensional metrology for workforce development.

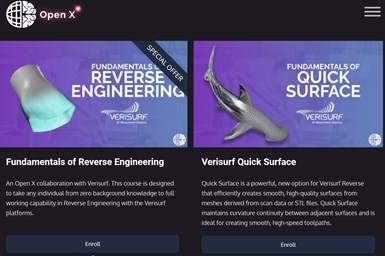

Verisurf Software has partnered with Open X, an interactive learning platform, to provide comprehensive courses on dimensional metrology and specific application areas. Current courses include reverse engineering (which includes fast 3D scanning to 3D printing workflows) and powerful 3D surface modeling. Future courses will include portable inspection and programmable CMM inspection.

“Technology continues to grow exponentially in today’s manufacturing environment,” says Cody James, CEO at Open X. “Skilled workforce development struggles to keep up, with many considering access to advanced training inaccessible, which can cause confusion for some about the viability of their career paths or career trajectory.”

Verisurf Software has long developed and supported metrology software solutions rooted in model-based definition (MBD). At the heart of the MBD is the absolute authority to define a part or entire product provided a defined 3D data set, including all necessary GD&T annotations for inspection, measurement, analysis, tool building and reverse engineering.

MBD has helped define the need for experts in dimensional metrology, the measurement science of length, size and dimension measurement in 2D and 3D real world and digital space. This science compares, analyzes and verifies the physical real part to its CAD model. Over the last two decades, dimensional metrology technicians have been in high demand, especially within tier one aerospace entities and their supply chains.

“At Verisurf we have always maintained a philosophy of developing practical metrology solutions. Our software is one of the easiest to learn and use…supporting all CAD file formats and virtually any new or legacy coordinate measuring machine,” says Ernie Husted, president and CEO of Verisurf Software. “We feel it is our responsibility to support our customers and manufacturing employees at large with high-quality training and support. This is the driving force behind our partnership with Open X.”

Related Content

-

Understanding Errors In Hand-Held Measuring Instruments

Different instruments (and different operators) are prone to different errors.

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

-

Determining Out-of-Roundness at the Point of Manufacture

George Schuetz, Mahr Inc.’s Director of Precision Gages, offers these techniques for measuring roundness on the shop floor.

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)