CAMWorks 2020 Provides SolidWorks Support

HCL Technologies has developed CAMWorks 2020 with enhancements designed to assist machine shops in advancing their Smart Manufacturing practices.

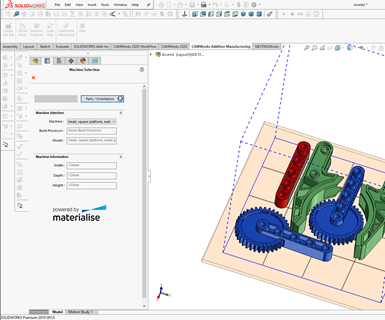

HCL Technologies’ CAMWorks 2020 includes support for 3D printing of SolidWorks assemblies, the CAMWorks ShopFloor product, intelligent probing functionality and automatic tab machining.

The CAMWorks Additive Manufacturing module, powered by Materialise, has extended 3D printing functionality to SolidWorks Assemblies. Multiple parts from the same assembly or different assemblies can be nested onto the build platform, and CAMWorks automatically generates the build supports.

CAMWorks ShopFloor enables machinists to view solid models, viewfull simulations of CNC programs and edit machining data on the shop floor without a CAD/CAM system, the company says. All of the CAM data from the 3D digital models is captured and placed in a digital container, helping to eliminate instances when parts are cut without the most recent edits. CAMWorks ShopFloor also supports 3D models with MBD (model-based definition) and PMI (product and manufacturing information) data to avoid errors that often occur when part data is transferred from 2D drawings or other formats.

Touch probe support is said to save time and eliminate errors that can occur with manual part setting and inspection. CAMWorks automatically selects the probing cycle based on the face/feature selection. A full set of touch probe tools has been added to the standard tool set with new parameters for probe shank and stylus.

Automatic tab machining is designed to provide support for parts requiring additional workholding, eliminating the need to machine soft jaws or design special workholding fixtures for subsequent machining operations. Programmers input the desired number of tabs, width and thickness, and CAMWorks automatically generates the tab machining details. Tabs can be equally spaced or precisely located using distance and/or offsets. Users can specify minimum segment and arc radius and are given multiple options for lead-in and lead-out.

Related Content

-

Improve Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

-

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

-

Finally, A Comprehensive Software Solution Designed for Small Job Shops

Zel X from Siemens is an integrated software application that consolidates collaboration, design, manufacturing, and operations into a comprehensive, easy-to-use solution. From RFQ to delivery, it’s a more efficient way to handle quotes, manage jobs, make parts, and collaborate with teams of all sizes.

.png;maxWidth=300;quality=90)