Hexagon's PC-DMIS 2020 R1 Eases Use of Portable Measuring Arms

PC-DMIS 2020 R1 offers features, capabilities and an enhanced user experience to portable measuring arm operators and those who scan and create point cloud data.

Share

PC-DMIS 2020 R1, available from Hexagon’s Manufacturing Intelligence division, offers features, capabilities and an enhanced user experience to portable measuring arm operators and those who scan and create point cloud data.

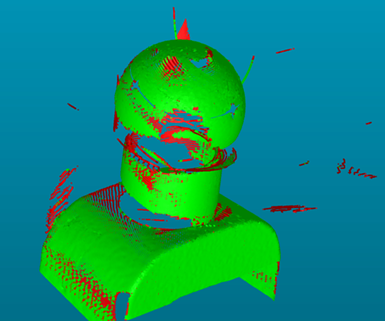

Guided Portable Execution streamlines the creation and execution of contact Auto Features. This is said to take the guesswork out of manual measurement paths by guiding the user through the measurements, showing where measurement points need to be taken in red and points already captured in green, while automatically scaling and rotating to the active Auto Feature. Users of scanning devices can now show the point cloud data as a mesh display, selecting a predefined profile from the portable scanning widget toolbar. The point cloud noise reduction filter automatically removes any points too far away from the global cloud. Filter sensitivity is adjustable.

The Protect feature, introduced in PC-DMIS 2019 R1 to help users version control their measurement routines and add levels of traceability to their processes, has been enhanced with the addition of a Supervisor role. Ideal for companies that follow a multi-level approval process, this feature enables restrictions on who has the authority to certify or reject measurement routine changes submitted by the programmer, the company says. Home Page was introduced in PC-DMIS 2019 R2, offering a more intuitive way for the user to manage and access their routines with links to resources, information and forums on the PC-DMIS home screen. In 2020 R1, this has been improved with the addition of example measurement routines and preloaded best practice templates, as well as the capability for users to create and share their own templates.

Related Content

-

Marathon Precision’s Engineering Playground: One Shop’s Secret to Sustaining High Tech, Low-Volume and High Morale

Half an airplane on the wall, a ten-foot metal dragon, and a full-blown recording studio might not scream “manufacturing efficiency,” yet Marathon Precision proves otherwise. Here’s how forging, complex CNC operations and staff-driven creative projects combine to fuel the shop’s productivity and profitability.

-

Understanding Structured Light Scanning Measurements

Structured light scanning is used to create a digital twin of a manufactured part, but we must understand the measurement reproducibility to best use the data.

-

A Balancing Act for Differential Gaging

Differential gaging measures using two devices, which has advantages over standard, comparative measurements using a single sensing head. These include the ability to measure size without regard to position.

(1).png;maxWidth=300;quality=90)