Hoffman Group Expands Parabolic Performance Cutting Tools

Hoffmann Group USA has expanded its Parabolic Performance Cutting (PPC) series with a set of indexable inserts and Garant PPC solid carbide barrel milling cutters for high-alloy and hardened steels.

Share

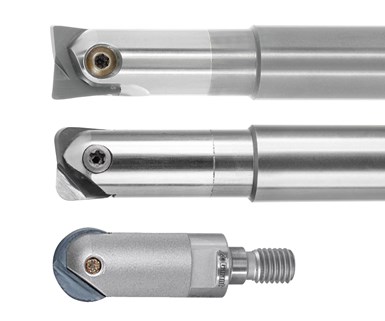

Hoffmann Group USA has expanded its Parabolic Performance Cutting (PPC) series with a set of indexable inserts and Garant PPC solid carbide barrel milling cutters for high-alloy and hardened steels. The PPC process, also known as barrel milling, is a type of ball-nosed slot drill cutting operation primarily used for finishing free-form surfaces.

Compatible with Garant copy milling cutters and tool bodies, the straight or stub point conical inserts are an alternative to PPC solid carbide cutters. According to the company, the PPC cutoff inserts effectively machine flat faces and freely accessible surfaces without interference contours in steel, high-alloy and hardened steels, stainless steel, and aluminum.

In addition to the new PPC indexable insert, the Hoffmann Group has optimized three versions of its PPC solid carbide barrel milling cutter for hard machining. The new tools have a tangential, conical or stub-point conical form and are also suitable for finishing flat faces and large surfaces with interference contours, as well as deep and hard-to-access cavities.

Related Content

-

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Custom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.