New Software From HCL CAMWorks Integrates PrimeTurning

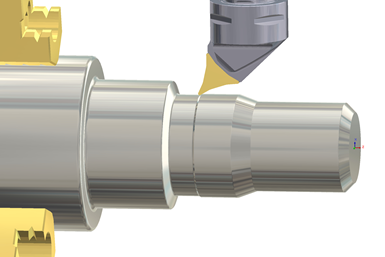

HCL CAMWorks 2021Plus supports Sandvik Coromant’s PrimeTurning, which achieves increased feeds and speeds, shorter cycle times and longer tool life.

Share

HCL Technologies (HCL) announces the release of HCL CAMWorks 2021Plus, which includes multiple technology databases and new tutorial task panes.

According to the company, HCL CAMWorks 2021Plus is one of the first integrated CAM systems to support Sandvik Coromant’s PrimeTurning, which uses CoroTurn Prime Type-A and Type-B tools in conjunction with unique toolpaths to achieve increased feeds and speeds, shorter cycle times and longer tool life.

PrimeTurning offers the flexibility for turning operations in all directions. The shape of the CoroTurn Prime tool inserts, combined with toolpaths that turn in the opposite direction of conventional turning processes, enable the user to achieve a much smaller entry angle and better chip control. This reportedly allows the machine to achieve a higher feed rate – typically two to three times faster than conventional feed rates – while still maintaining the same close tolerances and quality finishing. The direction of the toolpaths provides the ability to machine right up against a 90-degree shoulder on parts. PrimeTurning also spreads load and high heat over a longer distance, which is claimed to extend tool life up to 500% longer than conventional turning methods.

HCL CAMWorks 2021Plus also offers the ability to save and use multiple technology databases (TechDBs) to capture preferred machine settings, tools and operation details. In addition, the system includes a new tab in the SolidWorks task pane, which opens to Home, Learn and Alerts tabs. The Home tab provides CAMWorks users with access to information on promotional offers, customer stories, upcoming webinars and other announcements. The Learn tab gives easy access to CAMWorks tutorials, tips & tricks, and how-to videos. The Alerts tab supplies access to view and download software updates.

Related Content

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.

-

Blueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

-

AI Creates CAD Files From Scan Data

While 3D visual scanners are useful, converting a visual scan to a usable CAD file can be a time-consuming process. With generative AI, it may be much simpler and faster.