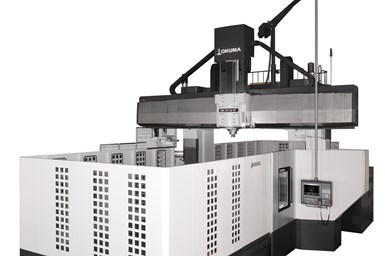

Okuma Launches New Double-Column Machining Center

Okuma’s MCR-BV is capable of five-axis contouring and five-sided heavy milling applications. The company says these heavy-duty applications are made possible through the machine’s powerful integral motor and spindle, as well as an expanded work envelope.

Share

Okuma America Corporation has debuted a new double-column machining center (DCMC). This new machine – the MCR-BV – is the seventh machine offered in the company’s double-column machine line-up.

Designed as a machine for five-face machining applications, the MCR-BV is also reportedly capable of five-axis contouring as well as five-sided heavy milling applications. Okuma says these heavy-duty applications are made possible through the machine’s powerful integral motor and spindle, an expanded work envelope and a rigid table that is 30% thicker than previous models. A range of attachment heads are compatible with the machine, enabling for a wide range of unique part shapes to be created, as well as many multitasking machining functions to be performed.

The MCR-BV features a table size of 2,000 mm × 4,000 mm (78.74" x 157.48") to 3,000 × 12,000 (118.11" × 472.44"), as well as a spindle speed of 6000 min⁻¹ (a 10,000 min⁻¹ option is also available). The spindles have a motor power of 43 kW (57 hp), and the MCR-BV’s rapid traverse is: X: 30 m/min (98.43 fpm), Y: 32 m/min (104.99 fpm), Z: 15 m/min (49.22 fpm). In addition, the machine has a magazine capacity of 50, 80, 100, 120 or 180 tools.

Additional machine features include a fast automatic tool changer (ATC) and a smaller, faster auto attachment changer (AAC), both of which are said to enable the MCR-BV to increase productivity while performing heavy cutting or high-accuracy finishing.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

SPC Innovations Milling Attachments Boost Productivity

PMTS 2025: SPC Innovations Inc. showcases multispindle attachments that can increase productivity, reduce secondary operations and enable for quick job changeovers.

-

Stability Maps for Milling

Selecting stable radial depths of cut for 2.5D milling.