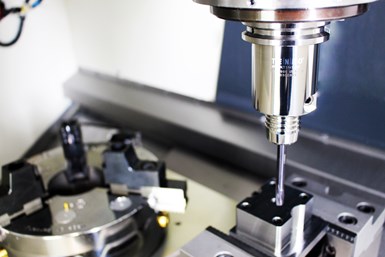

Schunk's Hydraulic Toolholder Features Imbalance Correction

Constructed of durable hardened tool steel, the Tendo Platinum V2 reportedly improves stability, stiffness and clamping force to support sustained accuracy throughout its life.

Share

Schunk has announced the launch of the Tendo Platinum V2 hydraulic toolholder. Schunk claims the new toolholder, which was designed and manufactured in the USA, brings manufacturers the most advanced direct clamping toolholder in the industry.

The Tendo Platinum V2 features an ergonomic, slim outer profile for easy actuation. According to Schunk, imbalance correction is carefully designed into the body profile. Constructed of durable hardened tool steel, the V2 reportedly improves stability, stiffness and clamping force to support sustained accuracy throughout its life.

The Tendo Original, with three rings, was developed in 1978 and was the first in the market to feature a run-out/repeat accuracy greater than or equal to 0.003, balance G2.5 25,000 rpm and no risk of damage when clamped without the tool. Schunk latest iteration of this technology is the Tendo Platinum V2.

Related Content

-

Rego-Fix’s Center for Machining Excellence Promotes Collaboration

The new space includes a showroom, office spaces and an auditorium that will enhance its work with its technical partners.

-

Platinum Toolholding System Enables Quick Changeovers

The U-Tec changing system enables a standard ER output live tool to accept various adapters for different applications, enabling quick changeover of tools on almost any lathe or mill using a single tool.

-

T.J. Davies Retention Knobs Maximize Cutting Tool Life

Custom-made retention knobs are sized to fit the machine tool and spindle or toolholder to extend the life of existing machine tool assets.