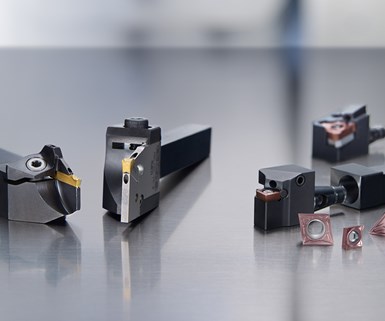

Seco's QC Toolholder Increases Swiss-Type Insert Indexing Efficiency

Seco’s modular QC (Quick-Change) toolholders for Swiss-type machining is designed to enable fast, easy and repeatable insert indexing and tool changes.

Share

Seco’s modular QC (Quick-Change) toolholders for Swiss-type machining are designed to enable fast, easy and repeatable insert indexing and tool changes outside of tight machine workspaces. For ease of use, the QC toolholder allows users to remove both cutting heads and inserts as a single assembly, then index and reinstall them. Manufacturers may also use this system to exchange cutting heads and inserts with a second set more efficiently. The cutting head also features double carbide pins for accurate, consistent and secure insert mounting and indexing.

The line includes cutting heads for general ISO turning, multi-directional turning (MDT), threading and parting off. Shanks are available in metric sizes of 10, 12 and 16 mm, and inch sizes of 0.375", 0.500" and 0.625".

The toolholders also feature Seco’s Jetstream Tooling and Jetstream Tooling Duo technology for chip control, surface finish quality and extended tool life. Jetstream Tooling directs high-pressure coolant through the QC Toolholder to the cutting zone. Jetstream Tooling Duo, available on a selection of cutting heads, adds a second coolant channel to the underside of the holder. The second coolant channel can be switched off if needed.

Related Content

-

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

-

Automation is for Everyone

Not just for large shops, automation can help even the smallest shops solve labor challenges and become more profitable and efficient.