Siemens NX Update Adds Model Based Definition

Siemens’ NX Model Based Definition adds support for non-geometric data within CAD digital twins, adding to their accuracy and utility for the production process.

Share

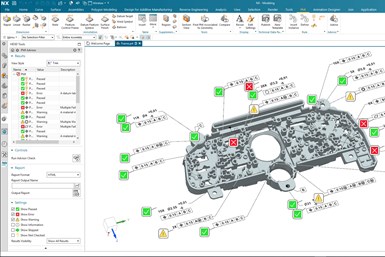

Siemens Digital Industries Software has updated its NX software with a rules and knowledge-based approach to Model Based Definition, which builds in best practices and leverages artificial intelligence to improve productivity. NX Model Based Definition provides data sets that define a variety of characteristics beyond size and shape to improve the comprehensiveness of digital twins. By including non-geometric data within the CAD model, engineers can now produce a complete digital definition of a product in an annotated and organized manner, creating alignment throughout the production process.

Siemens says the patented NX Model Based Definition technology, a first to the industry, solves many challenges companies face when digitalizing the design process and transitioning from 2D to 3D. In trying to replicate a drawing-based workflow in the context of 3D CAD design, many companies end up with a 3D drawing, which does not have the tools to capture the true business intelligence needed to take advantage of the digital twin and digital thread.

Designers and engineers can use NX Model Based Definition to automatically create and reuse data, adding more intelligence to the model, and subsequently leverage the data to inform other products and decisions – moving to a model-based enterprise. Avoiding the manual process of data validation and correction can help enterprises leverage their designs in a new and innovative way, enhancing productivity across the business.

Related Content

-

How Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

-

The Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.