Waterjet Machine Creates High-Precision, Complex 3D Parts

IMTS22: Hypertherm’s OptiMax waterjet cutting machine provides faster and more accurate print-to-part cutting.

Share

Hypertherm, a U.S. based manufacturer of industrial cutting systems and software is showcasing its OMax waterjet products. Products on display will include the OptiMax, a new generation of waterjet that is said to provide faster and more accurate print-to-part cutting, while reducing downtime. OMax waterjet systems enable users to create high-precision, complex 3D parts.

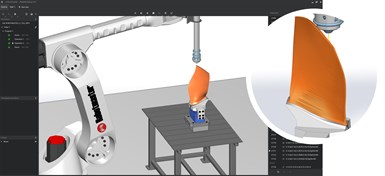

Hypertherm’s Robotmaster team is also demonstrating the latest version of its offline programming software for robots. Robotmaster software reportedly takes robot programming time down from hours to minutes with an intuitive programming workflow and powerfully integrated CAD/CAM functionality.

Hypertherm’s plasma and OMax waterjet cutting products are engineered and manufactured for use by companies around the world to build ships, airplanes and railcars, as well as construct steel buildings, fabricate heavy equipment and more. Its products include industrial cutting systems, CNCs, and software trusted for performance and reliability that result in increased productivity and profitability.

Related Content

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

-

Addressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

(1).png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)