February 2016 Product Spotlight Slideshow: Grinding

This month’s Modern Equipment Review Spotlight focuses on grinding machines of various capacities.

The slideshow below, based on our February issue’s Modern Equipment Review Spotlight, includes grinding equipment for a variety of applications.

Click through for details and see the links below for more information on each of these machines.

-

Kellenberger’s Varia universal cylindrical grinding machine

-

Erwin Junker’s Jucrank cylindrical/non-cylindrical grinding platform

-

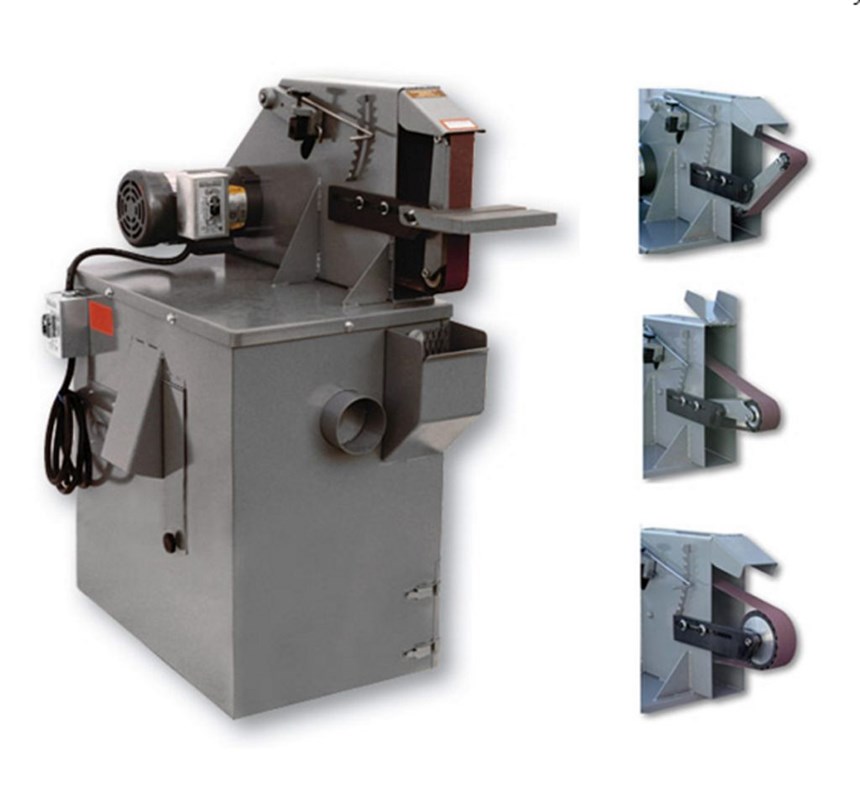

Kalamazoo Industries’ S272V belt grinder

-

Samputensili’s SG 160 Sky Grind dry grinding machine

-

Suhner’s BEX 15 WW-ER 25 spindle for robot arms

-

Vomat’s FA filtration systems for grinding oil

-

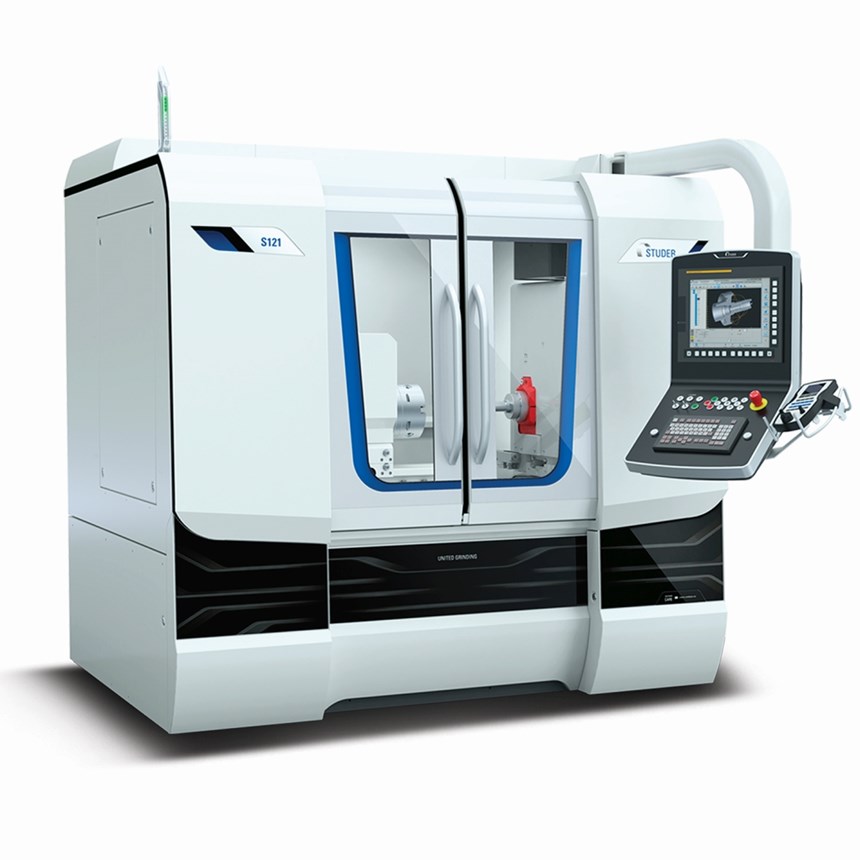

Studer’s S121 universal cylindrical grinding machine

-

Agathon’s Leo Peri insert grinding machine

Related Content

-

Grinding Wheel Safety: Respect The Maximum Speed

One potential source of serious injury in grinding comes from an oversight that is easy to make: operating the wheel in an over-speed condition.

-

Buying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

-

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.