Workholding

Workholding refers to any device that is used to a secure a workpiece against the forces of machining. The most basic workholding device is a simple clamp, but workholding can also involve complex fixtures that are custom-built for particular parts. Other common workholding devices include vises and chucks, as well as indexers or rotary tables that are able to change the part’s position while it is held, so the machine can reach various features. In most machining applications, workholding also locates the part. On a machining center, for example, a vise or fixture may also provide the precise position and orientation where the machining program expects to find the workpiece.

ESSENTIAL READING

VIEW ALLCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

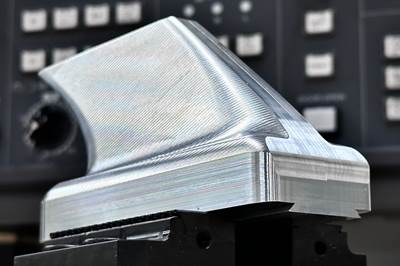

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreWhen To Use A Collet Chuck

Don't assume the standard chuck is the right workholding for every lathe application.

Read MoreWorkholding 101

No universal workholding solution exists, so machine shop employees should have a basic understanding of multiple ways they can secure workpieces.

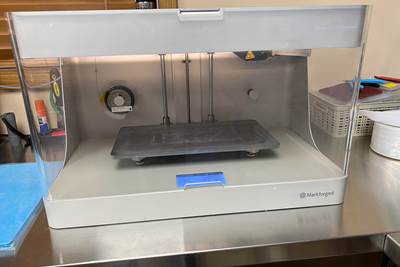

Read More3 Uses for a Composite Polymer 3D Printer in a CNC Machine Shop

When RPG purchased its metal 3D printer, a polymer printer was part of the deal. Three uses this job shop has found for this fused filament fabrication system.

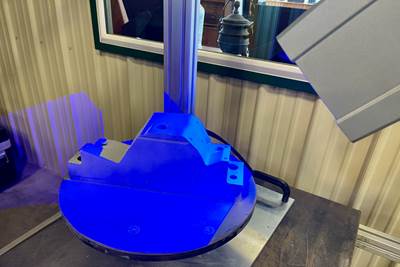

Read MoreVacuum Workholding for Thin Parts: First Episode of The One-Person Shop

A new video series looks at technology and practices for thriving as a very small machining business. In this episode, how workholding using air pressure permits rapid setup of parts too delicate to be held in a vise.

WatchLatest Workholding News And Updates

Ceratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

Read MoreFairlane Workholding Components Enable Modular Positioning

Fairlane Products Inc.’s Swivots workholding components swivel, pivot and tilt to compensate for angles and irregularities of the workpiece.

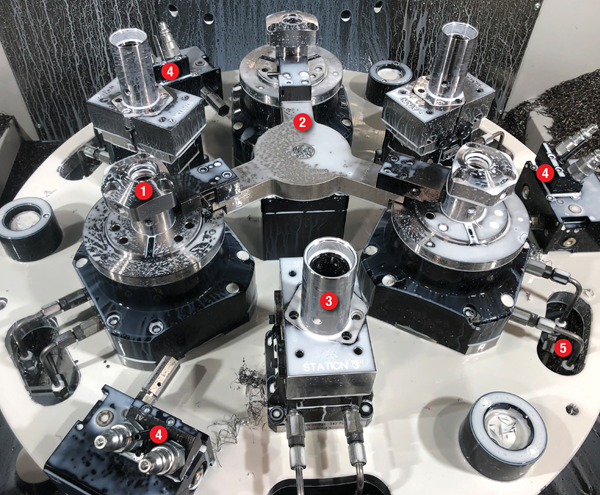

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreDillon Soft Top Jaws Improve Concentricity, Chuck Balance

The soft jaws are designed to provide better concentric performance chuck balance, as well as enable a longer jaw life because of the increased jaw accuracy.

Read MoreJergens Workholding System Clamps Challenging Workpieces

The Adaptix vise jaw system is designed to accommodate part configurations, adapting to asymmetrical and other features quickly.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreFeatured Posts

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

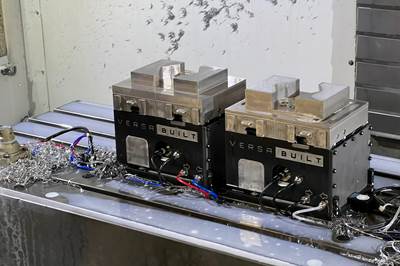

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreFixturing Castings Made Simple Through Adhesive Workholding

When a casting proved too malleable for traditional gripping, Thomas/Euclid Industries adopted — and succeeded with — Blue Photon adhesive workholding.

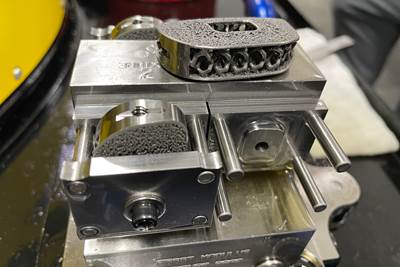

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

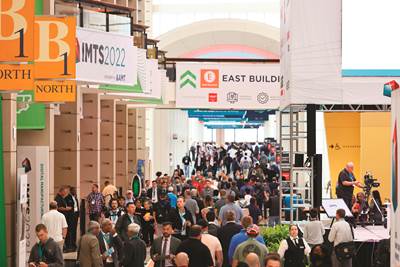

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

WatchFAQ: Workholding

What is workholding?

Workholding refers to any device that is used to a secure a workpiece against the forces of machining. The most basic workholding device is a simple clamp, but workholding can also involve complex fixtures that are custom-built for particular parts. Other common workholding devices include vises and chucks, as well as indexers or rotary tables that are able to change the part’s position while it is held, so the machine can reach various features.

When should you use flexible workholding?

For shops that handle short-run and one-off jobs, flexible workholding is key to producing work cost-effectively. This might involve quick-change workholding that speeds setups, or solutions that leave the sides of parts free for machining, requiring fewer setups.

When should you use automation-ready workholding?

As more shops add automation, they will need workholding systems that are compatible with the systems they’ve implemented, whether they’re robots, pallet systems or something else.

When should you use ID Workholding?

ID workholding, such as expanding mandrels, has a number of benefits and is suited to a range of applications. These fixtures can provide full access to a part’s OD, providing a rigid, even hold that increases accuracy.

What are some tips to consider when using five-axis workholding?

1. Size the Five-Axis Machine Correctly

2. Consider Augmenting Dovetails

3. Get Out of Your Comfort Zone

What is a collet chuck?

The collet chuck is an alternate workholding device that, like the jaw chuck, also uses mechanical force to hold the part being turned. While a collet chuck lacks the capacity for the same wide range of workpiece sizes that a jaw chuck can accommodate, it offers advantages related to speed, accuracy and productivity that may be crucial for certain jobs.

Source: When To Use A Collet Chuck

Workholding Supplier Categories

- Chucks, Self-Contained

- Dividing & Indexing Heads

- Actuators, Hydraulic & Pneumatic

- Chucks, Gear

- Vises & Vise Jaws

- Mandrels

- Guide Bushings (for Swiss Lathes)

- Angle & Sub Plates

- Chucks, Special

- Chucks, Collet Type (for Workholding)

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Indexers & Rotary Tables

- Collets for Workholding

- Clamps & Fixturing Devices

- Chucks, Precision

- Steady Rests

- Centers, Live & Other

- Pedestal Type Fixtures & Tombstone Blocks

- Chucks, Magnetic

- Fixturing Systems

- Workholding, Custom

- Chuck Jaws & Collets

- Chucks, Index

- Chucks, Power

- Chucks, Diaphragm

- Arbors, Expandable Workholding

- Chucks, Vacuum

- Chucks, Jaw Type

.png;maxWidth=300;quality=90)