Share

Tungsten inert gas (TIG) welding has been the traditional method for building-up worn or damaged mold and die surfaces prior to subsequent hand finishing or CNC machining to complete a repair. However, pulsed laser welding technology, which has been popular in Germany for decades, is gaining acceptance here in the United States as an option for mold repair (as well as other welding applications).

These welders fire a laser beam in 5- to 10-millisecond pulses that melts the base workpiece metal and filler wire that is deposited and then re-solidifies the weld pool before the next pulse. It offers high peak power, but low heat input into the base metal compared to continuous TIG and other welding operations. In fact, most workpieces are said to be cool to the touch immediately after welding.

Blair Learn is president of Alpha Laser-US, the North American distributor for Germany-based Alpha Laser, which manufactures Nd:YAG and fiber laser-welding, cladding and hardening equipment. Mr. Learn says that while the pulsed laser-welding operation itself currently is not as fast as TIG welding, pulsed laser welding offers three advantages:

1. Pulsed laser welding shortens overall repair time.

Prior to TIG welding a large mold component, it must be heated slowly. After welding, cooling must be gradual, too. This is necessary to prevent the base metal from cracking. However, heating and cooling can take hours, delaying the manual bending or CNC machining work needed to complete the repair. This controlled workpiece heating and cooling is not necessary with pulsed laser-welding equipment due to the low heat input. In addition, it is not necessary to cut the electrical power to a press when a mold remains installed during welding (as is common for very large molds). That is because pulsed laser welders do not require a ground wire to be attached to the mold as is required with TIG welding. The laser welding process also provides the accuracy to weld small details and areas without accidentally hitting adjacent features or surfaces. Laser welding can be done with welding wire as thin as 0.003 inch in diameter, which decreases machining time afterwards.

2. Pulsed laser welding minimizes workpiece hardness reduction.

Compared to pulsed laser welding, TIG welding creates a deeper heat-affected zone (HAZ). The HAZ is the portion between the melted metal and unaffected base metal under it that undergoes adverse metallurgical changes, growing the grain structure and softening the metal. For TIG welding, the HAZ can be as deep as 0.15 inch, while the typical range for pulsed laser welding is 0.008 to 0.012 inch. The larger HAZ for TIG welding means a greater reduction in hardness of the metal in that zone. For TIG welding, the material in the HAZ is softened by 15 to 22 HRc points, compared to 2 to 4 points using pulsed laser welding. This damage, when done to a molding component, can decrease wear life. As a result, a subsequent heat-treating operation might be required for a mold block that is repaired via TIG welding.

3. Pulsed laser welding provides more repeatable results.

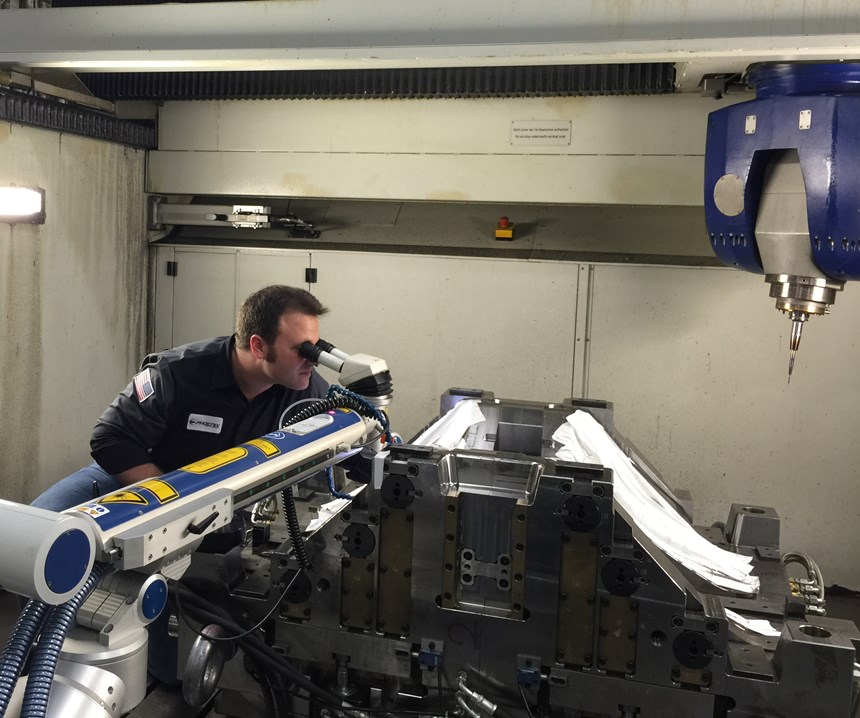

There is more art to manual TIG welding than pulsed laser welding. Depending on a TIG welder’s skill level, the bead path can include peaks and valleys. Conversely, pulsed laser welding enables users to start and stop the operation at precise positions while depositing a more consistent bead height. Pulsed laser welders such as Alpha Laser’s mobile Alflak and ALM units, which are commonly used for mold repair, feature microscopes with crosshairs to enable operators to precisely position the laser beam. In addition, only four parameters must be adjusted for each job—voltage, frequency, pulse time and spot size (laser beam diameter).

These units can be operated manually, in semi-automatic mode or in full CNC mode, although full CNC mode typically is used for production work, not mold repair. In semi-automatic mode, operators can lock any or all axes during laser operation to rotate at a set speed, weld in a straight line, or follow a complex angle with ease. Pulsed laser welders can also weld a spot as small as 0.004 inch, compared to 0.04 inch for a micro TIG unit.

Mr. Learn says new advances are making pulsed laser welders more capable. One is higher power. In 2010, the highest power available for an Nd: YAG pulsed laser welder was 200 watts (YAG lasers are more commonly used for mold repair than fiber lasers.) Since then, Alpha Laser and other manufacturers have developed 300-watt models.The company also offers 500-watt models. He says these have twice the welding speed of 300-watt models and can use larger-diameter filler wire to further increase metal deposition rates. The maximum wire diameter for a 300-watt model typically is 0.025 inch, while a 500-watt can use as wire as large as 0.0625 inch.

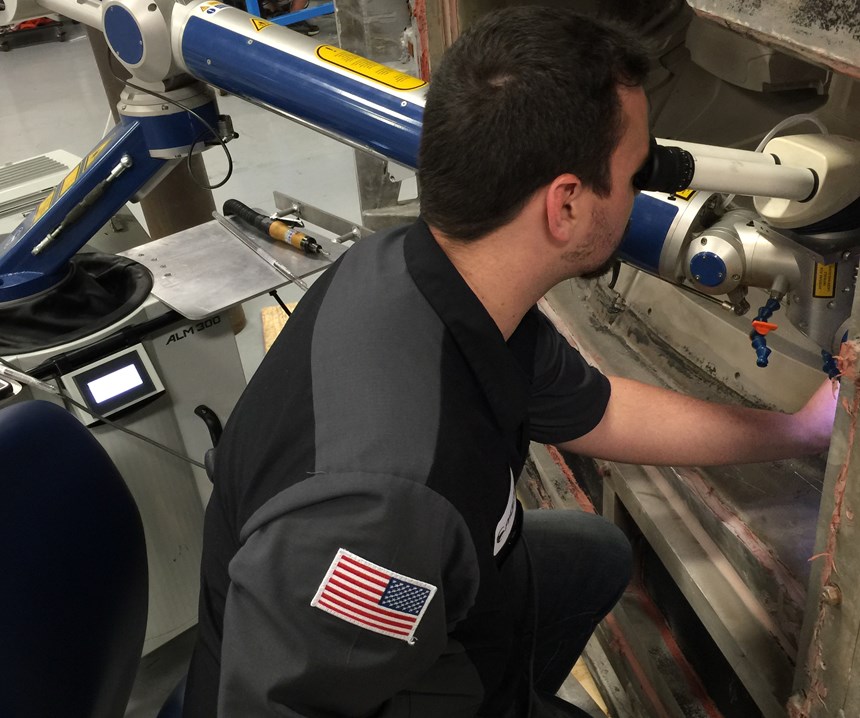

Another advance is improved mobility. Self-propelled Alflak models are available with continuous, tank-like caterpillar tracks. Mr. Learn says this enables the welding unit to easily drive from location to location, even in big plants where large molds, tooling or parts move on rails. These are the company’s largest laser models, offering arm extension of almost 5 feet. The laser head can rotate to face straight up or down to access a variety of workpiece features, too.

Mr. Learn started Alpha Laser-US two years ago, but has been owner of Phoenix Laser Solutions since 2008. This welding service company has four U.S. locations with a total of 20 pulsed laser welders. In fact, its Meadville, Pennsylvania, location has a metallurgical lab that performs weld testing and studies the effect of the HAZ in metals and the different use applications. He says this experience is helpful for providing training and assistance with customers’ specific welding applications.

Related Content

Punch Custom Tooling Supports Range of Manufacturing Processes

Punch Industry designs custom tooling for injection molding, stamping and equipment manufacturing processes.

Read MoreHow to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MorePunch Industry USA Pins, Punches Yield Precision Surface Finishes

PMTS 2025: Punch Industry USA exhibits its “polish-less” custom round and specialized shaped punches, button dies and mold pins.

Read MoreYCM Alliance Five-Axis VMC Enhances Machining Performance

YCM’s RX65+ VMC is engineered for speed, rigidity and accuracy in demanding applications.

Read More

.png;maxWidth=300;quality=90)