4 CNC Data Transfer Methods You Should Know

Modern CNCs enable transfer and backup of more than just machining programs.

Share

While CNC users emphasize CNC program transfers, there are other kinds of data that can be transferred using the same mechanisms.

Every CNC operator recognizes the need to get CNC programs into and out of a controller. For a job’s setup to be completed, its program must be in the CNC and ready to run. Once the job is completed, it is equally important to save it to an external device before deleting it, especially if the job will be run again and changes have been made during the program’s verification.

There are several program transfer mechanisms available, including local devices like USB flash drives and remote devices that use serial communications, Ethernet or wireless systems. Your company surely incorporates one or more of these methods to transfer CNC programs, and it’s likely that you use them regularly.

While most shops using CNCs place the highest emphasis on CNC program transfers, there are other kinds of data that can be easily transferred using the same mechanisms. While CNC program transfer has been available for many years, other data types are relative newcomers, so you may not know about them.

What CNC data transfer methods should you know about?

Here are four you should know about.

1. CNC System Data

Every CNC must be tailored to the machine tool to which it is attached. Even identical machines will require differences in system data to deal with issues related to spindle and axis drive systems (backlash and pitch error compensation, etc.). Machines made by different machine builders will have more substantial system data differences.

Data in this category includes parameters and programmable logic controller (PLC) data. It is imperative that you maintain the current version of this data in case of catastrophic failure within the CNC. Without a backup, a service technician may require days to get your machine up and running again.

Most current CNCs use the same transfer mechanism used for CNC programs to transfer system data. While you will not need to transfer system data nearly as often as CNC programs, get in the habit of backing up regularly.

2. Fixture (Work) Offsets

Companies that make qualified setups on their machining centers use the same fixture offset values each time a job is run. You may be including a series of data setting G10 commands at the beginning of your programs to ensure that fixture offset register values are properly set for the job.

The G10 technique works well if you have a limited number of fixture offsets to deal with. Remember, you must have one G10 command per fixture offset, and you must maintain them manually. If you make a change to a fixture offset value, you must also change the CNC program. Consider a cell that contains 30 pallets, each having four or more fixture offsets. That’s a lot of fixture offset values to maintain.

Current FANUC CNCs let you transfer all fixture offset settings by pressing a couple of buttons. The output fixture offset data file will be like any CNC program file. It will contain a series of G10 commands, one for each fixture offset, regardless of how many fixture offsets you are using. When it comes time to reload the fixture offsets, simply load the fixture offset file and execute it once.

3. Tool Offsets

Similar to fixture offsets, you can quickly output the current register settings for all tool offsets, including geometry and wear, for tool length and cutter radius compensation. Like the fixture offset data file, the file created will contain a series of G10 commands.

Loading tool offsets back into the CNC is just as easy, but tool offsets tend to be more dynamic than fixture offsets, meaning they often change when new cutting tools are assembled. But this could be a helpful feature if your company presets cutting tools using a tool length setting gage.

Outputting tool offsets after completing a setup could also be helpful for confirming that all tool length compensation values are within an acceptable range. External software, like Microsoft Excel, could be used to confirm that all cutting tool offsets are set and do not stray too far from a predetermined value.

4. Custom Macro Variables

Some CNC accessories use permanent common variables. Spindle probes, for instance, use them as calibration values. You may be using them for special applications of your own design, like timers, system constants and part family variables.

Like fixture and tool offsets, you can easily output the custom macro permanent common variable registers with current FANUC CNCs. And again, the data file will be comprised of a series of G10 commands to set each one.

Since it is quite easy to overwrite a permanent common variable intended for another purpose, and since you may be unsure of whether any of your machine accessories is using permanent common variables (and if so, which ones), it is a good idea to create a backup file for custom macro variables before developing any custom macro application that uses permanent common variables.

Though techniques vary among CNCs, FANUC allows you to transfer fixture and tool offsets as well as custom macro variables using the F_INPUT and F_OUTPUT soft keys (file input and file output, respectively) from the related display screen pages. Like CNC programs, outputted data will be transferred to the currently selected output device.

Related Content

4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read More6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreUnderstanding Process Damping in Milling Operations

Despite the advances in modeling machining operations over the past decades, process damping remains a topic of interest, including new tool designs that increase the effect.

Read MoreRead Next

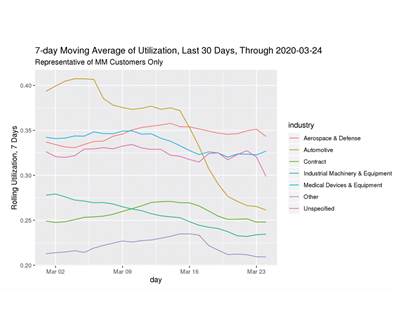

Can Sharing CNC Data Lift the Machining Industry?

Masses of anonymous metrics arrive ahead of even the leading economic indicators and help machine shops benchmark performance.

Read MoreOEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More

.jpg;width=70;height=70;mode=crop)