A Machine Designed With Contract Shops In Mind

This five-axis, moving-column machine features a table configuration allows C-axis rotation of small- to medium-sized parts as well as fixturing of very long workpieces.

Share

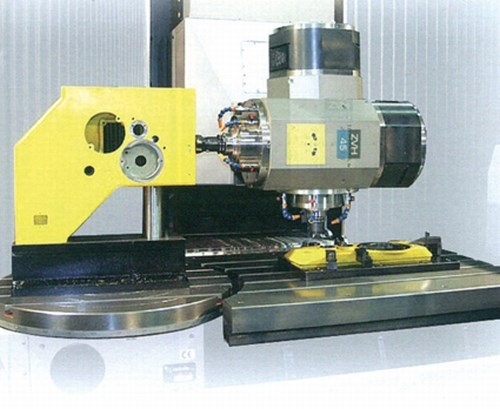

A contract shop must be versatile to adapt to the different materials, part geometries and lot sizes thrown its way. However, a shop can only be as flexible as the equipment it uses. The ZVH five-axis, moving-column machine from Ibarmia is an alternate platform designed for changing and challenging production needs. Its atypical table configuration allows C-axis rotation of small- to medium-sized parts as well as fixturing of very long workpieces. (Ibarmia equipment is manufactured in Spain and available in the United States through United Precision Services in Cincinnati, Ohio.)

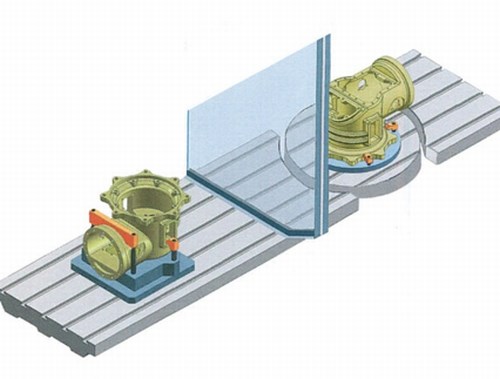

The ZVH machines feature a stationary main table that has an integral C-axis rotary table (see images to the right). Because the top of the rotary table is flush with the main table, there is no loss of machining envelope as would be the case when installing an auxiliary indexer on a machine. Combined with the machine’s B-axis tilting head, the rotary table permits full five-axis machining or positioning to access five sides of moderately sized parts in one setup. The rotary table lends itself to turning operations, and the company says it may soon offer this capability on the ZVH platform.

By positioning the rotary table so that its T-slots are in line with those in the main table, long parts or multiple small parts can be fixtured. In addition, the machines are available with a central, retractable partition to separate the rotary table from the rest of the main table. This allows operators to safely set up parts on one half of the table while parts are machined on the other side of the guarding. The ZVH machines are available in four sizes. The largest offers an XYZ machining envelope of 6,000 by 1,000 by 860 mm.

The machines have heads that offer B-axis rotation of -105 to +105 degrees from vertical. The heads are offered in contouring and positioning versions. The contouring head allows true four- and five-axis machining (when combined with C-axis rotary table motion). The positioning head uses Hirth gears to mechanically lock the head in 1-degree increments. Two spindle versions are available—a 19-kW, 15,000-rpm model for smaller machines and 25-kW, 9,000-rpm model for larger machines. The ZVH machines come standard with a 30-tool-capacity ATC, but 40- and 60-tool versions are available.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

-

Results-Driven Innovation on Display at Mazak's DISCOVER 25

DISCOVER 25 attendees will enjoy keynotes and panel presentations, and have a chance to tour the Mazak iSMART Factory where the company “uses Mazaks to make Mazaks.”