A Streamlined Alternative for Automated Tool Manufacturing

This automated, single-machine system enables tool manufacturers to completely grind mixed batches of varying tool types and sizes unattended.

Share

Many cutting tool manufacturers face the same fundamental challenges as job shops. They are pushed to produce a wide range of tool versions in small batches and in short order. Installing a dedicated, tool-grinding production line with a number of single-process machines is oftentimes impractical because of the time wasted retooling for new jobs as well as the large amount of handling and WIP associated with transporting workpieces from machine to machine.

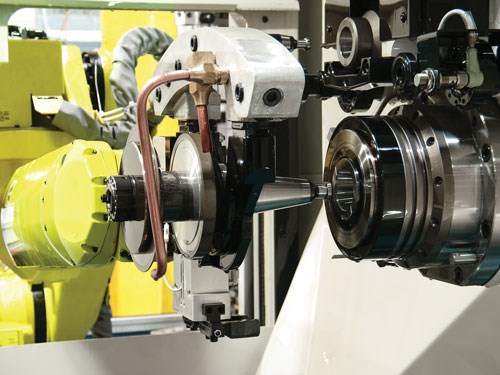

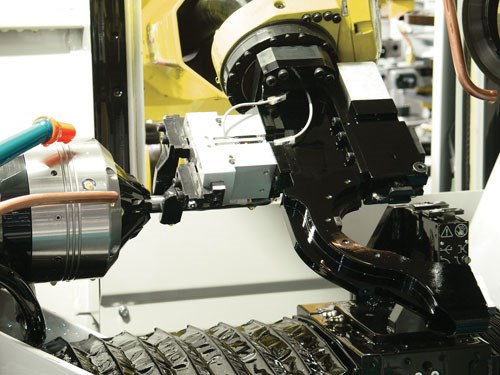

The TXcell from Australian-based Anca (its U.S. headquarters is located in Wixom, Michigan) is an automated, single-machine system that enables tool manufacturers to completely grind mixed batches of varying tool types and sizes unattended. An integral robot loads both tool blanks and grinding wheelpacks. The company calls this approach “blanket” grinding because the system enables manufacturing finished tools from blank stock within a single, compact platform.

The heart of the system is an Anca TX7+ CNC grinding machine with a 49-hp, direct-drive induction motor offering maximum spindle speed of 10,000 rpm (an optional 15,000-rpm spindle is available). An enclosure on the side of this machine houses the robot, wheelpack storage stations and tool pallets. The system accommodates as many as 21 wheelpacks for wheel diameters as large as 300 mm, while its four tool pallets (three for blanks and one for completed tools) can hold as many as 220 tools apiece. The pallets accept tools as long as 325 mm with diameters ranging from 3 to 32 mm. The robot, a Fanuc M-21iA with six degrees of freedom and ±0.10 mm repeatability, changes both wheelpacks and tools in 15 seconds.

The company says a stepped drill offers a good example of the TXcell’s advantages. This type of drill would traditionally require five separate steps and five different machines to cut stock to length, grind the shank chamfer, grind the cone point, grind the OD step sections and finally grind the tool’s OD, flutes and point. The TXcell is able to complete all of these operations in one setup as well as post-process operations such as polishing, brush honing, tool measurement and packing while the machine is grinding another blank.

In addition to offering a smaller capital investment and operating costs than multiple-machine tool production processes, the small-footprint TXcell can reduce inventory levels and stock holding costs for cutting tool manufacturers. The system also consumes less power, occupies less floor space and has just one coolant system. Plus, single chucking for all grinding operations is said to ensure maximum accuracy and minimal tool runout.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Automation is for Everyone

Not just for large shops, automation can help even the smallest shops solve labor challenges and become more profitable and efficient.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

.png;maxWidth=300;quality=90)