Automotive Cylinder Coating for High-Production Applications

Daimler’s Nanoslide cylinder bore coating technology can now be incorporated into an automated process for high-volume production.

Share

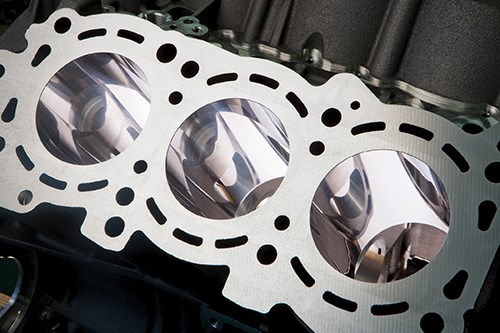

Some years ago, Daimler AG developed what it calls Nanoslide technology, a cylinder bore coating process for aluminum engine blocks that offers an alternative to cylinder sleeves/liners. The technology uses a twin-wire-arc spraying process to continuously melt iron/carbon wires and spray them onto the cylinders with the help of a nitrogen gas flow. Spray-particle velocity ranges from 60 to 80 meters per second and spray particle temperature reaches 2,000°C. Compared to other thermal coating processes, Nanoslide is said to be more cost-effective, reliable and repeatable while generating favorable frictional conditions between the bores and pistons/piston rings.

Daimler started development of the coating technology with small, series production of AMG engines, including the 6.3-liter V8. Since 2006, it has treated more than 80,000 engines. The company has recently partnered with Germany’s Gebr. Heller Maschinenfabrik GmbH, which has developed the Heller Cylinder Bore Coating (CBC) system for automated, Nanoslide cylinder bore coating, machining and inspection in high-production applications.

The CBC system uses a Heller MC20 machining center to perform fine boring, roughing, Nanoslide coating, rough honing, finish honing (to expose pores) and finish machining. Heller says the total cycle time for an eight-cylinder engine, including part load/unload, is 5 to 6 minutes. Engine blocks can be directly loaded into the machining center or mounted on a swiveling workpiece exchanger.

A key aspect of the Heller CBC system is the final fine-boring process of the coated cylinders. This is said to take half the time of traditional honing while delivering a more consistent cylinder finish and form because of the machining center’s axial spindle orientation to the bore. The company says tooling cost is also less compared to traditional honing.

Cylinder inspection is performed using a Jenoptik IPS 100 bore inspection sensor system which, in a single pass, uses CMOS imaging technology to provide a 360-degree panoramic view of a cylinder surface. This device automatically detects surface defects such as scratches, porosity and blow holes.

Related Content

-

The Benefits of In-House Toolmaking

The addition of two larger gantry routers has enabled a maker of rubber belting products to produce more tooling in-house, reducing lead times and costs for itself and its sister facilities.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

Inside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.