Bow Machining I

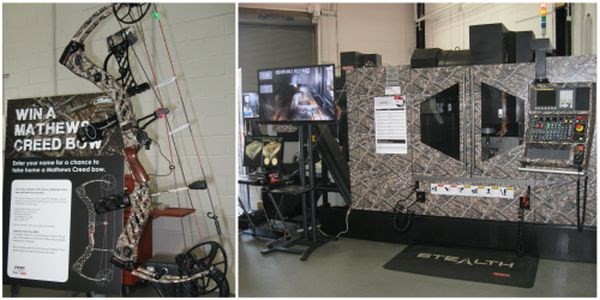

Toyoda's Stealth vertical machining center is part of a manufacturing process that bow maker Mathews Inc. uses to produce 300,000 bows per year.

Share

Toyoda's Stealth vertical machining center is part of a manufacturing process that bow maker Mathews Inc. uses to produce 300,000 bows per year. The machine is used to rapidly mill out the many pockets in the honeycomb-like form giving the bow its light weight. At its “Toyotech” event last week—an open house with both machining demos and technology seminars—Toyoda had the machine painted in hunting camouflage to draw attention to Mathews’ success with this VMC.

Coincidentally, this was one of two bows featured at simultaneous events by Chicago-area machine tool companies. Read about the other.

Over a dozen machine tools were on display and/or running demos at the event,

include various large machines and systems. This flexible manufacturing system

was an example.

Related Content

-

How I Made It: Walter Minehart

The 24-year-old mechanical engineer and machinist just founded his own one-man shop, Minehart Machine, in San Luis Obispo, California.

-

Results-Driven Innovation on Display at Mazak's DISCOVER 25

DISCOVER 25 attendees will enjoy keynotes and panel presentations, and have a chance to tour the Mazak iSMART Factory where the company “uses Mazaks to make Mazaks.”

-

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.