Brass Machining Optimizations Save Job Shop Time and Money

With the help of TechSolve Inc., Nolte Precise Manufacturing Inc. optimized a brass part and saved $22,000 while opening up significant extra production time.

Share

Nolte Precise Manufacturing collaborated with TechSolve Inc. on process improvements for a brass fitting part, resulting in more than 200 hours of bonus production time per year. Information and photos for this story were provided by the Copper Development Association.

If he could, Doug Coster would make all his parts from brass because of the material’s exceptional machinability. Despite his confidence in the speed and ease in which brass can be cut, Coster was surprised by the significant cycle time reduction his shop, Nolte Precise Manufacturing Inc. in Cincinnati, Ohio, realized after collaborating with manufacturing technology firm TechSolve Inc. on a job involving a brass fitting. The resulting process not only yielded a yearly savings of $22,000 for Nolte, but also opened up about 220 additional hours of annual production capacity for one of its Swiss-style lathes.

Throughout its 100-year history, Nolte has distinguished itself as a contract manufacturer specializing in complex precision-machined parts. Its customers are mostly multi-regional original equipment manufacturers (OEMs), and the shop serves clients in the hydraulic, aerospace, defense and firearms industries, among others.

Nolte is a low- to medium-volume production shop, but Coster says he prefers to focus on hours of machining instead of job volumes. This is because the shop produces parts that can involve hour-long run times for a single workpiece — a 20-piece job can take up a lot of production time. Typical job lot sizes can involve 10 to 40,000 pieces per year, and while part quality is mandatory, on-time delivery and competitive prices are also very important.

Notle makes parts from brass, aluminum and carbon-steel bars as well as stainless steel. Many customers specify their desired materials for their parts, but the shop will make recommendations when applicable and suggest different materials based on cost-effectiveness or machinability.

Due to Nolte’s smaller operational capacity, Coster says the shop focuses on how many quality pieces it can reliably produce each day. With price always impacting the equation, Coster says the shop values flexibility and creativity in finding ways to decrease internal unit cost.

Brass Benefits and Challenges

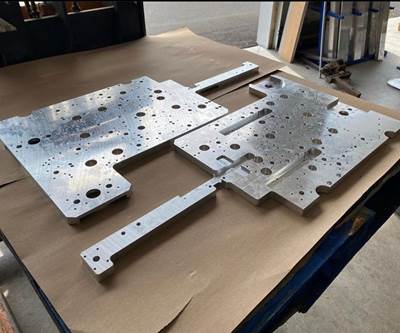

Nolte’s innovative outlook recently came into focus when the shop partnered with TechSolve Inc., a Cincinnati-based manufacturing technology specialist and business adviser, to optimize production of a brass fitting part Nolte has been producing since 2014. The part is for vacuum suction cups used to move glass components such as TV screens during assembly processes. While the customer specified the use of brass for its high machinability, part features like a milled hex, threads, a hole through its entire length and drilled cross holes make it a challenging application.

Nolte President Doug Coster says brass gave the shop’s operators the freedom to take more aggressive and innovative approaches to improve productivity without compromising on quality.

While Nolte could make the part from other materials, these materials could potentially introduce unwelcome machining challenges. For example, the shop would have to use lower speeds and feeds on steel alloys, which could result in higher machine and tool wear. Using aluminum would make machining fast, but built-up edges on tools, weaker material strength and stringy chips could create problems. Moreover, steel and aluminum alloys would have lower scrap value than brass. With brass established as the ideal material for the job, the challenge for Nolte was whether it could be even more productive with a part that was already running fast.

Systematic Optimization

For the collaboration, TechSolve and Nolte’s operators looked at the part objectively, taking a systematic approach to further optimize the process. The part run times are long, and Nolte machines them in unsupervised lights-out operations. The job volume is high enough that even improving the process by 1 second would result in significant cost savings.

To achieve these time savings, TechSolve advised Nolte to make numerous changes: optimize the part setup process, switch from single-point to form tooling and further improve a hex flat-milling operation. In addition, TechSolve recommended significantly higher speeds, feeds and depths of cut for some operations to fully exploit the high-speed machining potential of brass. With these process improvements, Nolte cut cycle time by 10 seconds (a 26% improvement), increasing throughput from 1,763 parts to 2,215 parts per 24 hours of production.

Coster admits he was initially skeptical that the optimization effort would have much of an effect on machine capacity, and that any attempt would be limited by the machine’s capabilities. He acknowledges the key role of TechSolve’s tooling suggestions in reducing cycle time, but says they would not have had the same results in another material. In the end, he says “brass gave our operators the freedom to take more aggressive and innovative approaches to improve productivity without compromising on quality. We wouldn’t feel comfortable trying these same things with other materials.”

He went on to say that any time the shop can open up additional machine time, as was the case with the brass fitting part, it helps improve profitability across the entire facility.

Related Content

Inside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreHow I Made It: Nushrat Ahmed: CNC Swiss Operator

By day, 21-year-old Nushrat Ahmed is a CNC Swiss operator making automotive parts. By night, she handcrafts crocheted items.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreRead Next

Machining a Complex Part in a One-Man Shop

Feature recognition and efficient workholding let this shop cost-effectively produce an intricate part that was bigger than the machine tool's travels.

Read MoreStudy Finds Brass Has Profit Potential for High-Speed Machine Shops

For machine shops with high-speed equipment already on the floor, brass represents an opportunity to capture new profits they might otherwise miss with other materials, according to the study.

Read MorePractical Approaches to Automation

Automation isn't just useful for large volumes of the same part. Today, it is increasingly being used in machine shops for high-mix, low-volume jobs.

Read More