CAM Software Saves Time in Micro-Precision Turning

JTD SAS implemented Esprit CAM software from DP Technology in order to solve the inefficiency of manually programming their CNCs. This saved programming time and ensured optimized cutting paths.

Share

Manually programming multitasking machines isn’t an easy task. In fact, it’s one that strained the capabilities of JTD SAS’s programming department, which was using manual CNC programming techniques. After investing in Esprit CAM software from DP Technology of Camarillo, California, the company was able to save programming time and ensure optimized cutting paths. Making regular use of these optimized machining cycles helped JTD reduce programming time from 90 to 10 minutes for some parts.

JTD, a French company with 30 employees, uses CNC machines to produce high-quality, micro-precision turned parts ranging from 1 to 60 mm in diameter in materials including stainless steel, titanium, plastics, steel, copper and bronze. These parts are used in the medical, defense, aerospace, automotive and railway industries. JTD primarily uses four types of machine tools—multitasking turning centers, single-spindle CNC lathes, fixed-headstock CNC lathes and conventional lathes—mainly from Citizen, but also by Miyano, Biglia and Tornos.

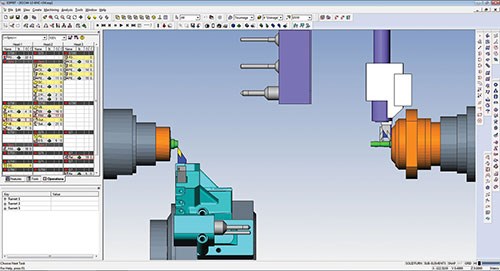

Recently, JTD increased its investment in multitasking equipment to completely machine a cylindrical part without removing it from the machine. In doing so, the company realized it also must invest in programming capabilities. This became evident as programmers used manual methods to separately program each spindle and turret, and then combine the programs using the machine’s control. The problem with this manual approach is that it was very difficult to move operations from one spindle or turret to another, and programmers couldn’t control when operations started on the different spindles. This resulted in unproductive time while one spindle or turret sat idle, waiting for the other to finish.

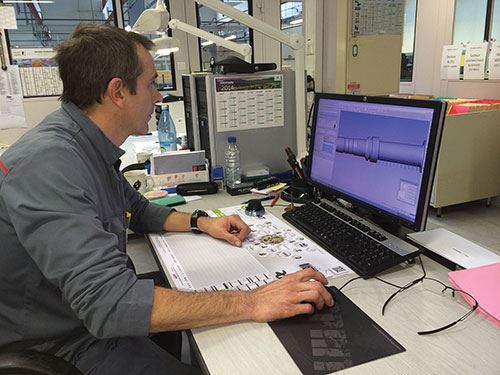

After evaluating several CNC programming systems, Managing Director Johann Thibaud says he selected Esprit based on its capabilities in programming multitasking machines, its strong technical support infrastructure and DP Technology’s record of continuously improving the software. He worked with CAM solutions integrator MHAC Technologies to install two seats of Esprit and train JTD’s programmers on turning, milling and EDM.

JTD also purchased another CAD software package to create solid models from the 2D drawings that its customers typically provide. The company upgrades these designs from 2D to 3D before producing the CAM program with Esprit.

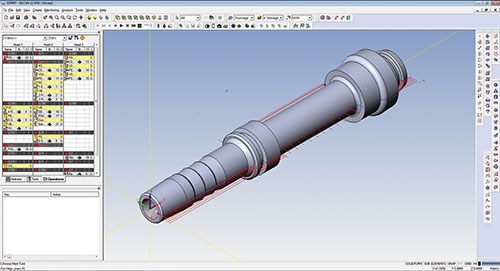

The advanced capabilities of Esprit have enabled the company to streamline the programming process. To begin, the part geometry is imported from a solid model produced by the design team. Esprit recognizes model features that normally correspond to machining operations, such as pockets, islands and grooves, and organizes them into a tree that includes the machining operations needed to produce them.

As the programmer reviews the machining tree, he or she can manually create, modify or re-order the features. The programmer can then apply machining specifications, which include a tool, cutting speed, feed rate and depth of cut, to each feature. In most cases, the machining operations have been defined and optimized in advance to maximize productivity. The programmer can also quickly create new operations from scratch when needed.

Machining operations are assigned to the spindles and turrets. Programmers can easily move operations back and forth between turrets and spindles, and set up sync points to control the timing of those operations. Programmers look for opportunities, such as when a spindle or turret sits idle, to make improvements and perform an additional operation. Finally, the programmer simulates the complete machining operation, including the machine, turrets and spindles, into a realistically rendered solid model. The simulation verifies the part geometry. Programmers also view the simulation to look for inefficiencies that can be remedied to reduce cycle time. After the programmer has validated the program on the computer, he or she uses the postprocessor to generate NC code specific to the machine tool.

JTD programmers also use the Esprit CAM solution to create machining cycles that manage differences and repeatability in families of parts. For instance, the company often receives orders for stainless steel aircraft parts with tight dimensional tolerances that are similar to parts it has produced in the past, says Technical Director Florent Lambert. To simplify part programming, the company creates a series of machining cycles that produce the complex features on these parts. Programmers can select machining cycles, input parameters to adjust dimensions and combine them to produce the new part.

This approach reduces the typical time required to program one of these parts from 90 minutes to only 10 minutes. Another advantage is that cycles that have already been proven out comprise the programs, making them more reliable and precise, Mr. Lambert says.

In the past, the size of the blanks or workpieces that serve as the starting point for machining were measured at a few points and then programmed manually. The tool path was not optimized, which caused the tools to wear out relatively quickly. With Esprit, JTD programmers can more accurately model the blank geometry and use efficient canned machining cycles for roughing operations, which results in substantially reduced tool wear.

“In one case, the life of a tool increased from 200 to 1,000 pieces,” Mr. Lambert says. “Overall, we have reduced our cutting tool expenses by 20 to 30 percent. In addition, we are able to hold

more accurate tolerances, and less time is lost in tool changes.”

Besides providing machining cycle advantages, Esprit helps JTD improve the accuracy of its sales quotes. JTD estimators use the 3D-design files to measure dimensions that are missing on the part prints and visualize geometric details that are not clear on the 2D drawings. Estimators can also quantify cycle time and parts produced per hour with Esprit.

Recently, JTD worked with a major German automobile manufacturer on a challenging project. JTD proposed combining several parts together into a single part with a complex geometry that required a combination of turning and milling operations to produce. The result was a substantial cost reduction due to the reduced part count. In the past, JTD would not have been able to produce this new part, because it could not have been programmed with manual methods. In the end, the company won a substantial new order due to its programming capabilities.

Related Content

Continuous Improvement and New Functionality Are the Name of the Game

Mastercam 2025 incorporates big advancements and small — all based on customer feedback and the company’s commitment to keeping its signature product best in class.

Read MoreCutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

Read MoreAerospace Shop Thrives with Five-Axis, AI and a New ERP

Within three years, MSP Manufacturing has grown from only having three-axis mills to being five-axis capable with cobots, AI-powered programming and an overhauled ERP. What kind of benefits do these capabilities bring? Find out in our coverage of MSP Manufacturing.

Read MoreShop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More