Cell Automates Multiple Part Change-Overs

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs.

Share

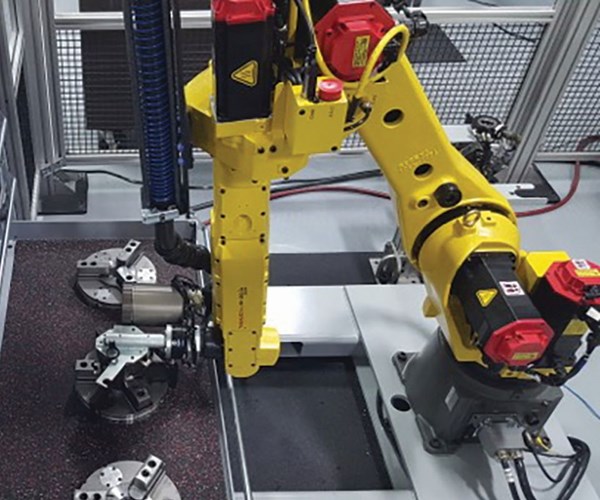

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs. This means switching among a number of significantly different parts, not just members of a part family. In the cell, a Multus multitasking, CNC turning center performs a number of operations on a series of parts requiring three different three-jaw chuck face plates. A FANUC M-20iA industrial robot loads part blanks, unloads the finished parts and exchanges the chuck face plates as required.

Read the full story in the IMTS Show Daily.

Related Content

-

Revolutionizing Production: How Smart Hydraulics Drive 24/7 Manufacturing Excellence

All World Machinery Supply helps a firearms manufacturer up its game and improve and increase output.

-

Addressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.