Share

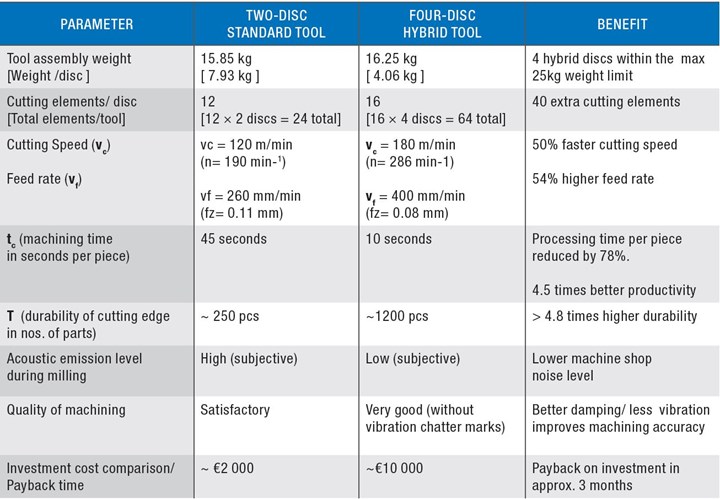

Quality cutting tools can be costly, but tool cost becomes less relevant when machining time per part drops by 78 percent.

This is the figure cited this past January by a European chain manufacturer that swapped a standard disc milling tool for a hybrid steel-composite model to speed the machining of forged steel chain links. The incorporation of lightweight carbon fiber reinforced plastic (CFRP) essentially enables bringing more tool to the cut without requiring a larger machine.

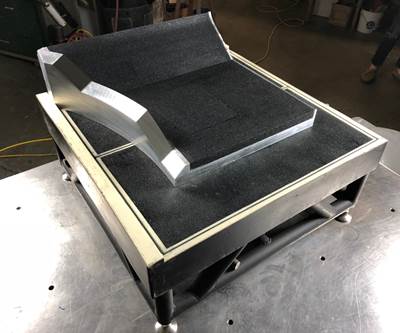

Replacing sections of steel with light but inherently stiff material enabled swapping a two-disc milling cutter for a four-disc model to reduce milling times by nearly 80 percent. All images courtesy of CompoTech and/or Hofmeister.

Underlying this triumph in milling is nearly a decade of intensive research and development into hybrid metal-composite constructions. Conducted by CompoTech, a composites engineering company, this research involves not just cutting tools, but also other links in the machining process chain: toolholders, spindles, and structural components of the machine tool itself. Humphrey Carter is business development manager at CompoTech, which conducted this research and developed the disc mill along with a cutting tool manufacturing partner. Based on a recent video call with Carter, as well as various research reports from CompoTech, one of the best ways to unlock the full potential of hybrid designs is also one of the most challenging aspects of expanding implementation: adopting a systems-wide approach to engineering new tools, machines and processes.

More Cutter, Less Machine

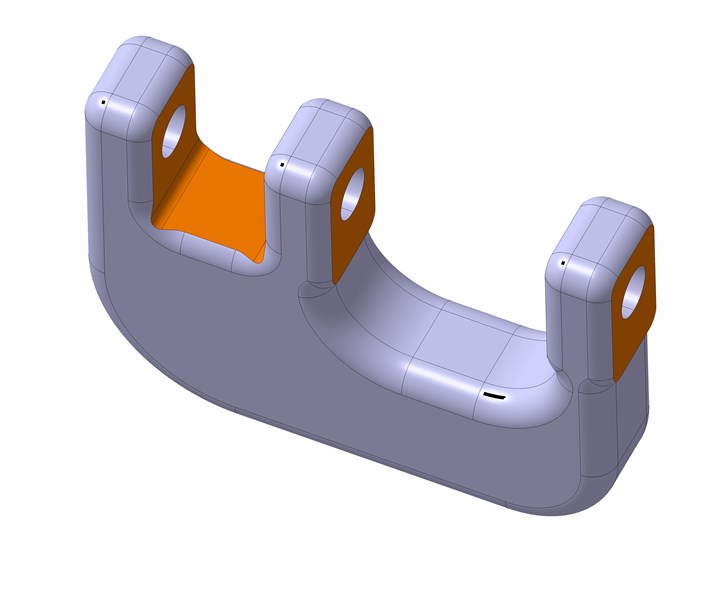

As depicted below, the chain link required milling the sides and bottoms of the forged, high-strength steel workpiece. Although the manufacturer was satisfied with the essentials of the milling process, a two-disc cutter proved insufficient to meet desired output levels. Adding two more discs would do the job, but each additional disc would add 7.3 kg of additional weight. Together, the four discs would be too heavy for the 25-kg weight limit of the BT50 L 150-mm master mandrel on the machine tool (a Doosan Mecatec HM63H twin-pallet HMC).

Milling the side and bottom faces of the forged chain connector link took 10 seconds using the new four-disc hybrid milling cutter, compared to 45 seconds for the two-disc metal tool.

Enter Hofmeister, a machining process engineering company and cutting tool specialist. Located near CompoTech in the southwestern Czech Republic, Hofmeister has been a long-term collaborator on experimental tool constructions that merge steel with lightweight, vibration-damping CFRP. The new milling discs consist of an inner steel ring for the mandrel, an outer steel ring lined with solid carbide inserts, and a central hub of hardened epoxy resin impregnated with ultra-high-modulus carbon fibers (“modulus of elasticity” is a measure of stiffness).

In addition to two additional discs, the hybrid tool offers more cutting inserts on each disc (16 each, versus only 4 on the previous, twin-disc tool). Weighing in at 16.25 kg (well within the weight limit), the tool enabled boosting speeds and feeds by 50 percent and 54 percent, respectively, without worry of compromising machine or part. Milling time dropped from 45 to 10 seconds per part (adding up to the nearly 80-percent overall reduction). Tool life improved, too. The hybrid composite cutter lasted through more than 1,200 parts before a tool change, compared to 250 parts for the previous, twin-disc model.

The chain link application demonstrates the potential to earn a return on investment for hybrid-composite disc milling within three months.

Broader Potential

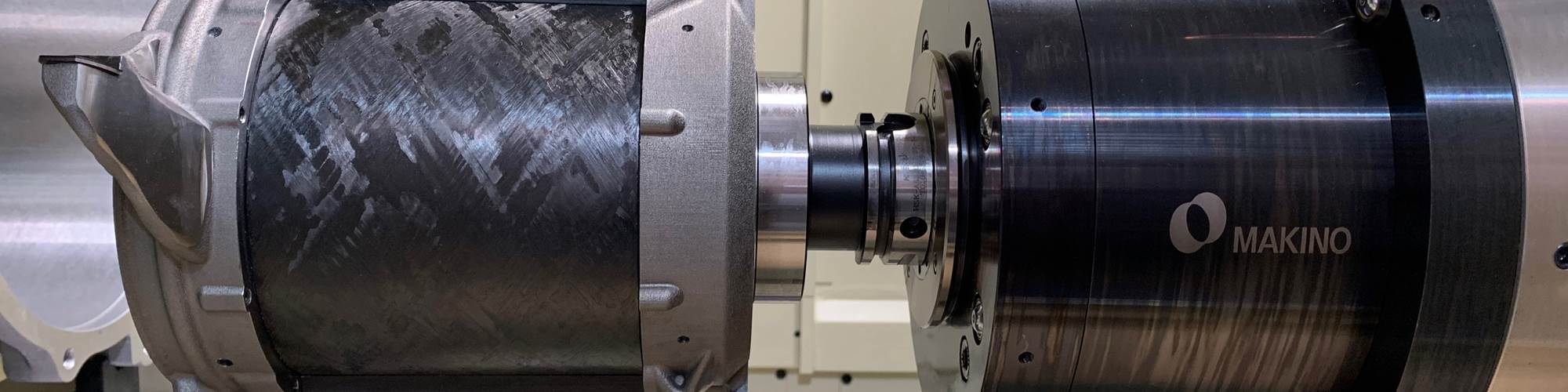

The disc mill stands out for its commercial success, but it is not the only recent example of the hybrid cutting tools’ potential. The picture below is from Makino’s booth at EMO 2019, where the machine tool builder demonstrated how its a51nx HMC could accommodate a much larger tool than otherwise would be possible in an electric vehicle machining application.

As demonstrated by Makino at EMO 2019, a chief advantage of hybrid metal-composite tools is the capability to employ larger cutting tools than a machine could otherwise accommodate.

This tool, as well as others that CompoTech and Hofmeister have developed, exhibits the same general advantages as the disc mill. Light weight translates to low inertia, which enables easier, more aggressive manipulation of the cutting tool. Along with its low mass, the material’s stiffness increases the material’s natural vibration frequency, thus improving damping. Finally, the material’s coefficient of thermal expansion (CTE) of CFRP is close to zero, which makes the tools better heat-resistors that can run without coolant. According to CompoTech, these properties add up to smoother, faster and more accurate machining — perhaps to the extent of eliminating separate finishing — as well as less wear on the cutting tool and the machine.

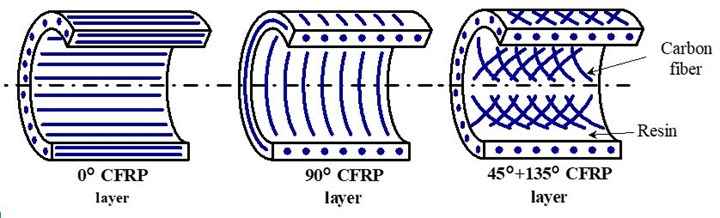

The process that makes these tool and spindle designs possible is CompoTech’s core competency: a composite-filament laying method that employs a six-axis robot to strategically and surgically fit sections of inherently stiff, lightweight and vibration-damping material onto an otherwise steel construction. This enables adjusting properties according to the application. Examples include strengthening a corner geometry, changing vibration frequency or controlling the direction of thermal expansion. Boring tools benefit particularly from the stiffness because they are long and narrow, and thus, particularly susceptible to bending forces.

This illustration from Kyoto University shows how three different layers and orientations of reinforcing composite material (carbon fiber reinforced plastic) can influence the performance of a CNC machine tool spindle. For example, the zero-degree layer influences axial thermal expansion, while the 90-degree influences radial thermal expansion. The cross-pattern layer in the third example provides torsion stiffness.

Particular advantages for longer, symmetrically rotational structures make toolholders and spindles natural targets for research as well. Some experimental spindle constructions employ composites for all material except bearing surfaces, threads and other critical contact points. As for the advantages of these constructions, Carter points to a recent study by Professor Atsushi Matsubara of the Department of Micro Engineering at Kyoto University. In testing, a hybrid spindle shaft that weighed 70 percent less than a comparable steel spindle exhibited 75 percent less displacement when heated to 70˚C. Lower inertia enabled accelerating to maximum speed (18,000 rpm) 17 percent faster than the steel version, and the spindle damped vibration 16 times better. Cutting depth increased from 5.5 to 10 mm as well.

Machine to Tool

CompoTech’s standard products, round and square composite beams, are already incorporated into industrial machinery. For example, gantry-style laser cutters incorporating composite beams with internal reinforcement reportedly move faster and more dynamically without reducing cutting tolerance. As for cutting tools, toolholders and spindles, “We came at this from a structures point of view — reduce weight, have higher natural frequencies, and reduce the energy of the moving parts,” Carter explains. “But what if the part you’re moving around is heavy? You’re paying for this expensive composite structure to move this heavy thing around. You have to think more globally.”

The Eagle Inspire laser cutting machine incorporates internally reinforced composite beams.

In fact, without a systems-wide approach, the advantages of a hybrid-composite construction can be entirely lost. For example, one CompoTech experiment targeted the spindle ram of a large CNC machining center. Testing demonstrated that reinforcing ductile cast iron with composite material significantly increased the ram’s damping compared to standard construction. The gain was achieved without significantly altering the design of the ram (such as its outer dimensions and connection interfaces with the machine). However, once the ram was actually integrated into the VMC, the benefits disappeared, essentially canceled out by other aspects of the machine’s design.

Much of the engineering for the disc mill reportedly involved ensuring that the interlocking geometry and steel bolts that sandwich the composite disc between the steel rings would provide sufficient rigidity and transfer of milling forces.

Experiments with toolholder assemblies reveal a similar dynamic at work on the end of the spindle. Vibration tests (tapping the suspended assembly with a hammer and measuring the response with an accelerometer) were performed on four different combinations of standard and hybrid-composite structures: a hybrid tool with a hybrid toolholder; a standard tool with a hybrid toolholder; a hybrid tool with a standard toolholder; and, for comparison’s sake, a standard tool with a standard toolholder. Although the hybrid holder-standard tool performed best, this might not be the case in a real-world application. As explained by a report on the test, “The question remains how the increased damping of the tool or tool holder effects the dynamic behavior of the whole machine, as the damping of the machine happens mostly in its connection interfaces.”

For now, “The technology is most efficient when designed to tackle one specific problem, rather than attempt to improve across a broad spectrum of the improvements that can be achieved with composites,” Carter says. The disc milling application is an ideal example. It demonstrates that when the application is right, commercial success for hybrid designs is by no means out of reach, and in fact is likely to become more attainable. In fact, results indicate a return on investment for high-volume disc milling application of only three months. Meanwhile, CompoTech continues to seek other applications where the payback justifies the costs, even as research and development continue to expand what is possible.

Related Content

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read More5 Tool Setting Techniques

Each tool setting technique has merit, and it depends on where you are as a shop and the type of work you do, as cost and efficiency all come into play.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreEight Articles to Understand Live Tooling

A roundup of the most read articles about live tooling on Modern Machine Shop.

Read MoreRead Next

Workholding Material Conforms to 3D Surfaces

A porous, easily sculpted material provides even vacuum gripping force throughout the entire contact area with the workpiece.

Read MoreComposites Specialist Makes CNC Chops Count

Machining capability drives evolution from race car builder to aerospace and defense contractor.

Read More