Determining Machining Effectiveness, Not Guessing It

KitchenAid uses Overall Equipment Effectiveness to determine in real numbers the impact individual machine tools have on parts production for its stand mixers. In doing so, it brings actual machining processes closer to ideal ones.

Share

With just a few mouse clicks at his computer, Brian Nakoneczny can get a true measure of how the three newest machining centers at Whirlpool’s KitchenAid Portables division are performing. He’s able to do that thanks to the company’s firm commitment to calculating, tracking and maximizing Overall Equipment Effectiveness (OEE). And it’s because of such concerted efforts (in addition to complete buy-in from upper management) that the manufacturer has been able to shrink the gap between ideal and actual machining execution.

Through OEE, the senior machining engineer can easily see how three prime equipment utilization metrics—availability, performance and quality—affect the production of key components for KitchenAid stand mixers. When combined, these separate elements generate a value that indicates how close a given machining process is to achieving its full potential. Specifically, OEE is the product of their percentages:

OEE = Availability * Performance * Quality

Processes that deliver an OEE of 85 percent or higher are considered to be world-class. So in this respect, OEE serves as a benchmarking measure against other manufacturers. But there is value in carefully examining the three contributors to OEE individually, too, in order to identify areas that need improvement.

KitchenAid is a good example of a manufacturer that succeeds by performing this latter exercise. It began collecting OEE data on some of its existing machines in 2007. Initial calculations showed that while quality (the ratio of good parts to total parts produced) really wasn’t suffering, performance (actual cycle time to produce a part) and availability (scheduled up-time less unplanned downtime) weighed down OEE. As a result, OEE percentages in the 60s and 70s were common.

Fast-forward to today. The new two-spindle machining centers the company recently installed in its Greenville, Ohio facility readily satisfy the quality and performance metrics needed to machine zinc mixer castings at a high OEE. So for KitchenAid (and presumably other manufacturers that have integrated advanced machining equipment), availability is the trickiest OEE factor to boost. Recognizing this, the company implemented an aggressive total productive maintenance (TPM) program to minimize downtime resulting from unplanned events. The TPM efforts consistently push machine availability to 90 percent or higher. In turn, that drives OEE for a machining process to the mid to high 80s and even low 90s in some instances. What’s equally impressive is the efforts to maximize machine availability for a new piece of equipment begin months before the machine even hits the floor.

RCM to TPM to OEE

KitchenAid is the iconic American brand that traces its roots to the first stand mixer introduced in 1919. Today, the latest versions of these 32-pound multitasking mixers are found in just about every well-equipped kitchen in the country.

The initial mixer component targeted for OEE process improvement was the zinc casting that forms the underside of the mixer’s signature tilting head (the part is called a gear case bottom cover). Each of these castings required six machines and an average of 7.5 operators across all shifts to complete the necessary operations. Because those machines had some miles on them, breakdowns happened frequently and disturbed production. Yearly maintenance cost on these machines approached $116,000.

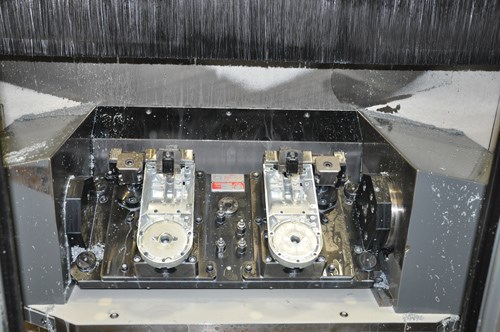

Mr. Nakoneczny and others believed a two-spindle machining center could complete all operations required to machine this particular casting. Besides drastically reducing setups, this alternate machine tool design offered the obvious advantage of machining two castings at once. After considering options from a handful of suppliers, KitchenAid purchased two DZ-15 two-spindle machines from Chiron to meet its growing production requirements. The machines feature two-sided, hydraulically actuated fixtures to allow both op10 and op20 work. A single operator would tend both machines.

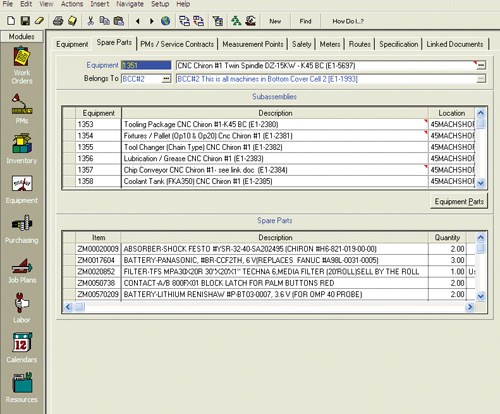

Approximately three months before the machines were to be delivered, the company laid the groundwork for its comprehensive TPM program by holding its first RCM event. RCM is an acronym for reliability-centered maintenance. An RCM team was formed that included Mr. Nakoneczny, a TPM leader, a machine operator, maintenance personnel and a representative from Chiron. The team met for a solid week to analyze every consumable component on the machine and list them in categories such as pneumatics, hydraulics, lubrication, fixturing, mechanical and electrical. The team then determined the expected life span for each component as well as its cost and availability from Chiron. Based on that information, the team decided whether to stock replacements for a given part in its consumables crib or to set up the part as a non-stock item it could quickly order from the machine tool OEM.

Preventive maintenance practices were also outlined during the RCM event to ensure every aspect of proper maintenance was in place before the machines were brought online. For example, the team determined a schedule to regularly test spindle motors and bearings. By taking decibel readings on spindles each month, it would be able to chart the readings and see if they were trending toward an upper limit. This would be an indication that a motor would likely soon fail. By taking this proactive approach, maintenance personnel could order a new motor rather than keep one in stock and schedule motor replacement for a weekend or a day when the machine was not scheduled to run production.

As the RCM event concluded, the company formed a TPM team for those machines that included the original RCM members and additional machine operators. Soon after the machines were installed, debugged and running production, OEE data collection and calculations began.

Determining OEE

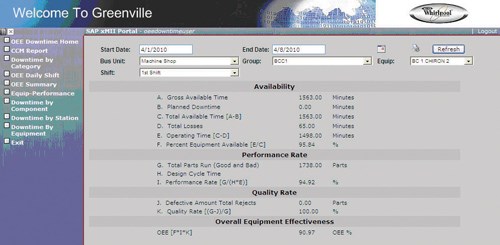

A screen screenshot to the right from KitchenAid’s OEE tracking software shows what’s involved in calculating the three OEE metrics. Quality is possibly the simplest OEE metric to determine. Its percentage is found by dividing the number of good parts by the total amount of parts produced. For each machine, operators perform spot checks of parts using hand gages and record this data on a job sheet that hangs from the machine. In addition, the quality department sends someone to the machines each day to collect sample parts for CMM measurement.

To determine availability, KitchenAid first establishes total available machine time. For this calculation, planned downtime (for scheduled maintenance, operator lunches and breaks, etc.) is subtracted from gross available machine time, which is based on the number of shifts the company runs at a given time. (It typically runs two shifts five days per week, but will run 24/7 at times.) Time for unplanned losses (for tool breakage, unpredicted maintenance and so on) is subtracted from the total available time to yield operating time. Dividing operating time by total available time yields OEE’s availability percentage.

Performance, which essentially tracks the speed of production, is based on the effectiveness of both the machine tool and its operator. This OEE metric is determined by dividing the total number of parts run (both good and bad) by the product of the cycle time and operating time. If machine cycle times are longer than expected, or if operators take more than the allotted time to load and unload parts, then the performance metric suffers.

In terms of the three individual OEE factors, KitchenAid strives to achieve 90 percent availability, 95 percent performance and 99 to 100 percent quality. These values will deliver a world-class OEE of 85 percent. In order to produce an OEE value that is truly reflective of an actual process, however, it’s vital that all personnel involved are adamant about dutifully collecting and recording accurate information. Otherwise, the calculated OEE offers no real value.

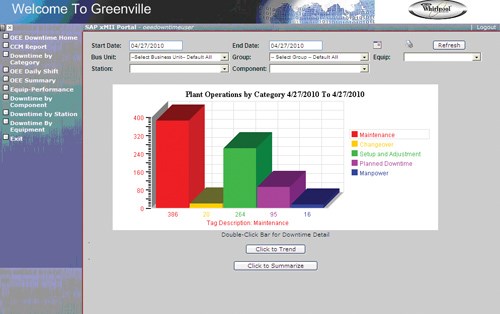

All OEE data is entered into tracking software that managers can easily review and analyze. They can look at OEE values by shift, machine and time period, for example. This makes it possible to identify the prominent individual issues that are adversely affecting OEE.

Another piece of software called Maximo (which interfaces with SAP) contains all the information gathered during RCM events, including machine documentation, drawings, replacement part details, training instructions and so on. The software also maintains an electronic inventory of consumables (as categorized during an RCM event) allowing managers to accurately determine maintenance costs (including both parts and labor) over a period of time. Barcode scanning helps streamline the data collection. To obtain a replacement part, an operator brings a barcoded tag assigned to a particular machine that is scanned in the crib. The software shows the part number and its location in the crib. The employee then scans the bar code where the part is stored as well as his or her ID card so the system can track who pulled the part.

Driving Other Changes

Since the initial OEE program with the two DZ-15 machines, KitchenAid has performed a second similar one for a larger Chiron two-spindle machine that produces a different mixer component (see the sidebar below). It has also held RCM events for a number of its existing machines—24 altogether—with the goal of minimizing unplanned downtime to maximize OEE.

This quest to limit machine downtime has led to other changes at KitchenAid. For example, it now uses preset tooling. Previous steps to replace a broken tool required an operator to obtain a tool from the crib, use a ruler to approximate the correct tool height, touch-off the tool in the machine and make the necessary offsets in the control. Now, tool stations near the machine are stocked with fresh, preset tools ready to load into a machine as needed. Each day, an employee checks tooling stations near each machine and replenishes the stations with preset tooling. The tools are assembled in the crib using a presetter from Regofix. Preset tooling offers another advantage in that it ensures accurate, repeatable tool heights. This is especially important for a two-spindle machine because a single Z-axis drive moves both spindles.

Finally, because the value of OEE depends so much on the information that’s collected on the shop floor, KitchenAid plans to streamline how data is entered. It will do this by installing touchscreen computer terminals at each machining station so operators can input information directly into the system. That way, another individual won’t have to input information that operators have jotted down on their job worksheets. This will speed and simplify data entry while minimizing the risk for errors that could adversely affect a machine’s true OEE.

Related Content

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Read MoreShoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read More

KitchenAid launched its second new-machine OEE project in the middle of 2009. It did this so it could more effectively produce the rounded, upper gear case housing that attaches to the bottom cover produced on the two-spindle DZ-15 machines. Complete machining of this part previously required five pieces of equipment. Maintenance was becoming an issue for the 12- to 14-year-old

KitchenAid launched its second new-machine OEE project in the middle of 2009. It did this so it could more effectively produce the rounded, upper gear case housing that attaches to the bottom cover produced on the two-spindle DZ-15 machines. Complete machining of this part previously required five pieces of equipment. Maintenance was becoming an issue for the 12- to 14-year-old  equipment, too. For this particular housing, KitchenAid purchased a larger two-spindle machining center from Chiron—a DZ-18 unit with a trunnion table that could fixture four workpieces at a time. OEE for this machine is often in the mid to high 80s, and maintenance costs are significantly less than the machines it replaced.

equipment, too. For this particular housing, KitchenAid purchased a larger two-spindle machining center from Chiron—a DZ-18 unit with a trunnion table that could fixture four workpieces at a time. OEE for this machine is often in the mid to high 80s, and maintenance costs are significantly less than the machines it replaced.