Finding The Right Words And The Right Process

This greeting card giant leverages hand-engraving competencies, digital media and high speed machining to produce press-ready dies so its cards are ready for the consumer's viewing pleasure.

Share

Have you ever felt lost trying to choose a greeting card out of the vast selection lining the racks? Consider how many dies it must take to produce all of the different greeting card designs using cut shapes or raised features. Now consider that the raised rounded dies Hallmark uses for its greeting card designs are all machined by just three operators. How is this possible? The company accomplishes this with high speed machining. After transitioning from a nickel forming process to a digital means of manufacturing that relies on high speed machining, Hallmark’s process now yields press-ready dies that are not only more consistent but are also less expensive to produce.

Advancing The Aesthetic

Hallmark represents roughly 50 percent of the greeting card market in the United States. Worldwide, the company employs more than 18,000 people, about 4,500 of whom work at its Kansas City, Missouri headquarters where the die design and manufacturing occur. Since its inception in 1910 by founder Joyce C. Hall, the personal expression specialist has grown an expansive product line that includes various brands other than its flagship identity. Represented in a network of more than 43,000 retail outlets in the United States alone, Hallmark’s presence extends to Crayola and Silly Putty products.

The same uncompromising attention to detail that allows the company to flourish and produce a profusion of thought-provoking sentiments and beautiful designs has also led Hallmark to reevaluate its die-making processes. The rationale behind essentially abandoning the previous nickel forming method involved irregularities in surface finish and unpredictability in terms of overall thickness and run quality with the dies.

While the company decided that expensive bench work had to go, the distinctive look of hand-engraving had to stay. Hallmark would have to figure out how to successfully replicate the hand-engraved look and still produce dies that could be transported directly from the mill to the press. This undertaking called for a multifaceted approach, one that would leverage the skill set of its hand engravers and the practicality of digital tools. High speed machining of the brass engraving dies would prove to be a crucial factor in upgrading the technology while optimizing processes.

Doug Bowen, a senior engineer at Hallmark’s Advancing Technologies division, recognized early on that engineers supporting the digital tooling initiative would need to closely collaborate with other “Hallmarkers” and tooling business partners to bring their vision to fruition.

“Part of successful implementation is clearly articulating that a temporary disruptive impact to a production area may represent the best long-term solution,” Mr. Bowen explains. “Sometimes this phase can involve long, often passionate dialogue to determine the most appropriate course of action.”

Creative Capital

Embracing a promising technology is the first step. However, technology alone does not provide the means to capture a sentiment in a card. Hallmark derives strength from the talents of a creative staff of around 800 artists, designers, stylists, writers, editors and photographers. Together they generate more than 19,000 new and redesigned greeting cards and related products per year. The company offers more than 48,000 products in its model line at any given time. Of this figure, about 11,190 cards require embossing or lettering using a custom die, and thus require the combined expertise of the company’s hand engravers and digital artists.

The embossing process produces a raised design. Embossed foil is also referred to as “raised rounded” or “raised foil,” whereas “flat foil” denotes no relief or raise in the paper.

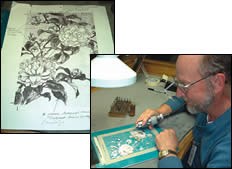

The notion that digital tools are still not as efficient in creating complex designs as a skilled artisan might seem unfathomable. However, anyone who has met one of Hallmark’s seasoned hand engravers would politely beg to differ. With an average of 25 to 30 years of experience, these dedicated “Hallmarkers” use tools that vaguely resemble dentist drills to painstakingly sculpt lavish designs in the magnesium plates. Through a proprietary data-capture process, these magnesium “blueprints” provide the basis for the digital design that will ultimately be used in the machining process.

“Certain repeated patterns or geometric shapes lend themselves to digital beautifully,” explains Phil Hammond, team leader of 3D reproduction at Hallmark. “By and large, Hallmark has been well-known for its organics, florals, landscapes—things of that nature.”

That said, Mr. Hammond conveys that the shift to digital is still a work in progress. Along with determining how to effectively model these intricacies within the realm of CAD/CAM software, the company is also learning how to machine them effectively.

After the design engraved in a magnesium die is scanned and imported into CAD/CAM software specifically for artistic forms—Delcam’s ArtCAM Pro 9—the file undergoes tweaking by an engraving artist. The program then creates the G code for the high speed machining centers.

All In The Details

Just as it draws on the talents of its creative, dynamic staff, Hallmark must also draw on the capabilities of high speed machining. Taking light, fast cuts enables the quick, consistent production of pristine, press-ready brass tools. But the process wasn’t always easy. The company first delved into high speed milling with what it describes as a “middle of the road” machining center. Even though the machine worked well for the dies, it wasn’t designed to endure the abuse that the company doled out. It could not withstand the frequent axis reversals within the mere 0.090-inch movement on the Z axis, which is all the dies require. The continual movement eventually wore out the Z axis components.

A search for an appropriate high speed solution that would meet the company’s requirements of performance, quality and serviceability ultimately resulted in the selection of a Vibra-Free from CompuMachine Inc. and an OmniRaptor from Datron Dynamics.

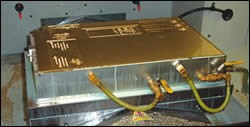

The high speed machining centers primarily mill raised round or “raised foil” designs, plus some emboss designs. The Vibra-Free works on 3D raised foil and flat foil designs, while the OmniRaptor is reserved for emboss work only.

Following the initial purchase in 2004, the company subsequently purchased three additional Vibra-Free machines within a span of 2 years. Now, all four Vibra-Free machines operate as close to 24/7 as possible. To preempt issues with the Z-axis servomotor, CompuMachine added a coolant mist to lubricate the Z axis.

According to CompuMachine, the Vibra-Free’s more than 2 GB of hard drive and its Ethernet link ensure that data starvation and exhaustive file compression routines are non-issues. The Fanuc 16i system includes High Precision Contour Control, as well as custom algorithms and surfacing techniques designed for thermal growth and maximizing tooling life. As the machining center’s name implies, the Vibra-Free offers the requisite rigidity to make smooth cuts at extremely high speeds.

“Rigidity is the foundation for achieving good surface finishes, and high speed is no exception,” comments Jesse Chen, product manager at CompuMachine.

The machine’s ribbed castings, precision ballscrews, precision way guides and wipers work in harmony to provide favorable surface finish and tolerance at high speeds, the manufacturer adds. The optional 55,000-rpm spindle supplied by Ibag is equipped with HSK tooling to provide further stability during the cutting process.

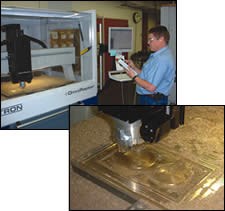

The other machine model used for dies, the gantry-style OmniRaptor has all the trappings of a machine built for high speed batch engraving of detailed workpieces, including a 60,000-rpm spindle. It also has a work area measuring 30 inches by 40 inches, ample enough to accommodate numerous dies to be machined at the same time.

Bob Murphy, sales manager at Datron Dynamics, recalls that Hallmark wanted to load about ten or 12 brass dies and then let the machine run unattended.

“They can basically generate one huge tool path and let the machine run and cut however many dies at once,” he explains. “The large bed minimizes operator intervention because it accommodates this full batch.”

This structural characteristic proves especially useful for Hallmark’s three-man machine shop because an operator can load a batch and then tend to other duties throughout the day. Also minimizing operator intervention is the engraving machine’s integrated probing apparatus.

According to Mr. Murphy, the Z-Correction probe reduces setup time, helps reduce operator errors and maps the surface of a part for precise depth engraving. The device compensates for uneven surfaces. Because it is mounted next to the spindle, the probe does not get in the way of the tooling. The pneumatically-retractable probe can be extended to measure either single points or custom matrices.

“Even if the plate was crooked, the probe would evaluate the surface and calibrate so that Hallmark could engrave over it,” Mr. Murphy says.

The engraving machine’s PC controller is useful for the company’s 3D artwork, as the file formats are typically rather large. The machines can be networked to foster easy data transfers. The Windows XP operating system affords the operator the flexibility to print files or even surf the Internet.

Rounding out the process are pre-balanced toolholders and collets as well as small cutting tools, which are mandatory for the fine detail work. Because the material is brass, high-end tooling generally is not needed. In fact, Hallmark has been able to standardize its tooling library, thereby minimizing the number of tools required for the sake of efficiency. Mr. Hammond adds that the shop can buy quality end mills in bulk to further maximize cost savings.

A Virtual Palette

Aside from the gains in machining efficiencies, the process is also significant for the consociation between the company’s hand engravers and digital artists. Following engraving in magnesium dies and scanning, these digital artists work with the designs in ArtCAM Pro 9. Senior artistic/digital engraver Rick Olsen is one of the digital artists that process the nearly 500 dies that brush through the computer-aided engraving department each month.

Working from the CAM software’s streamlined toolbox, he not only models a spectrum of designs using the features, but also generates tool paths efficiently by applying pre-defined milling strategies. The “Smart Engraving Wizard” has predetermined feed rates and depths of cut.

According to Mr. Olsen, the majority of dies will not be remachined. In fact, of the 6,000 dies machined on a yearly basis, very few of them will be duplicated. This means that generating correct tool paths in a timely fashion is essential, as there will not be a chance to use the program again. Equally as important is the capability to simulate cuts prior to making them.

“We are able to simulate every mill cutter path prior to machining with this package,” Mr. Olsen says. “We review everything but the G code, as we use a separate verification package for that.”

Crowning Achievement

As made evident by Hallmark’s notable savings in die machining in the first year alone, the company’s strategy has paid off. A healthy portion of the immense savings can be attributed to one final significant advantage of the new process—the precision fit between the die counter.

“There was a noticeable variance when producing dies with the old method,” Mr. Hammond says. “In the past, we might have wasted hours leveling dies to achieve uniformity. Now that we can supply manufacturing with tools that fit very precisely, we can increase press speeds and achieve better quality with less effort.”

In fact, by reducing the make-ready time, the company reports that it can also limit the extent to which it outsources the machining of its dies. Thus, the process not only makes both the machining and the press work more efficient, but it also gives the company better response time and greater internal control. Now that’s something to write home about.

Related Content

SolidCAM iMachining and Technology Wizard: Faster Machining and Longer Tool Life

Smarter toolpaths to tackle modern machining challenges.

Read MoreBlueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreCAM Copilots and the Next Digital Shift in American Machining

As AI reshapes programming and automation, Mastercam is betting on a future where human expertise and intelligent software evolve together on the shop floor. A conversation with Mastercam President Russ Bukowski.

Read More

.png;maxWidth=300;quality=90)