Finishing Fillets

Consider these finish-machining techniques that can enable you to maximize material removal rates prior to completing accurate, tight-radii fillets.

Share

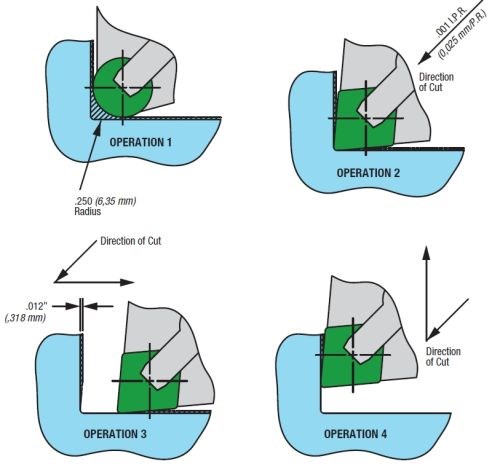

Here’s one method of finishing a fillet using an 80-degree insert.

Just because a pocket calls for a fillet with a tight radius doesn’t mean the entire thing should be rough-machined with a tool having that radius. As cutting tool manufacturer Greenleaf explains, radii like these typically are small. Therefore, a tool having such a radius is generally weak and must be indexed or changed numerous times if the plan is to use it to complete the entire operation. However, there are a number of effective methods available to finish fillet radii after performing roughing operations using a different, more appropriate tool. The company highlights four of them here.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Maximizing Milling Operations With the Right Cutter

Selecting milling cutters that are suited to the task at hand can reduce cycle times, improve part quality and save money. Here’s where three milling cutters excel.

-

Stability Maps for Milling

Selecting stable radial depths of cut for 2.5D milling.