Share

A collaborative agreement being overseen by the U.S. Department of Energy involves a deceptively simple test that can determine, based on the material and the depth of cut, which machining speeds are going to be stable and which speeds are not. All photos courtesy of Oak Ridge National Laboratory.

In September of 2018, a 146-page report issued by the Department of Defense landed on President Trump’s desk, presumably with a thud.

The report was a result of Executive Order 13806, issued by the President during the summer of 2017 — a period that coincided with heightened tensions between the United States and North Korea. The report’s title was self-evident: “Assessing and Strengthening the Manufacturing and Defense Industrial Base and Supply Chain Resiliency of the United States.” But its findings were, in a word, bleak.

Recognizing a critical threat to economic and national security posed by manufacturing labor shortages, production outsourcing, disinvestment in research and new technologies, and a thinly stretched global supply chain, Executive Order 13806 set in motion a “whole-of-government effort” to assess risks and propose recommendations “in support of a healthy manufacturing and industrial base.”

General James Mattis and the Department of Defense responded by creating an interagency task force that, for the next year, compiled data and information from defense contractors, academics, engineers, industry experts and company executives. The narrative of the task force’s concluding document — a richly detailed assessment that makes several broad recommendations to the President — is driven by one overriding judgement: The U.S. manufacturing and defense industrial base is plagued by critical weaknesses.

Under a section titled, “Decline of U.S. Manufacturing Capabilities and Capacity,” the report notes that the United States “once led the world in the innovation and capacity of its high-end machine tools sector,” then slipped into steady decline around the year 2000.

The report goes on to note that by 2011, China’s machine tool consumption accounted for 40% of the world’s total. And by 2015, U.S. investment in the machine-tool manufacturing sector had dropped to $4.6 billion, a fraction not only of China’s spending, but also behind that of Japan, Germany, Italy and South Korea. This, the assessment warns, presents a major threat to U.S. defense supply chains and, recalling a widely used military phrase, our ability to be “ready for the fight tonight.”

The fight that arrived on American shores less than two years later is being waged in a manner well outside the boundaries of conventional warfare. The word “pandemic” is nowhere to be found within the report’s pages. Yet, in several, crucial ways, COVID-19 has proved the taskforce’s assessment to be true. America’s reliance on foreign manufacturing — in this case foreign-made specialized personal protective equipment, or PPE — had devastating consequences during the early months of the pandemic. While U.S. manufacturing companies swiftly adapted by opening new production lines or converting existing lines to the production of PPE and medical hardware, it was too little too late for many.

The DoD’s report concludes by urging the President to sign a new Executive Order, this one directing the DoD and other federal agencies to implement more than a dozen proposals, including a federal effort to “Diversify away from complete dependency on sources of supply in politically unstable countries who may cut off U.S. access.” While U.S. reshoring initiatives are well underway — and have gained momentum because of weaknesses exposed by the pandemic — they face fundamental free-market challenges. Even if a wave of patriotism inspires company leaders to relocate production lines back into the United States, the report acknowledges that we would lack the skilled workforce needed to operate them.

But there is at least one, promising response to the DoD’s assessment that is already underway. It is a collaborative agreement being overseen by the U.S. Department of Energy that involves a deceptively simple test — a test that could radically increase throughput of the United States’ existing base of CNC machine tools.

What’s the Frequency, Kenneth?

In December of 2019, the U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) entered a two-year cooperative research and development agreement, or CRADA, with MSC Industrial Supply Co., the massive North American service provider and distributor of metalworking products. The plan calls for Oak Ridge to train MSC employees on how to conduct what is alternately called a tap-test, impact test, or machining dynamics test.

Once trained, this nationwide team of MSC “metalworking specialists” can travel their territory to conduct these tests on CNC milling machines and machining centers in machine shops large and small. The intention is to begin testing on new machine tools in order to establish a clean baseline of data from new equipment, along with optimizing existing machines and processes. MSC is launching the tap test service to customers under the name “MSC MillMax” this month.

The technology that the DoE is betting on is a topic that this publication has covered for more than 20 years. An article written in 1999 by editorial director Peter Zelinski explains the core principle behind impact testing: harmonics.

“(T)hink of a car that rattles. Drive faster, and the rattle intensifies… Now drive that car faster still. The rattle disappears. The noise that was so annoying at 25 mph may vanish at 40 mph — and resonant frequencies explain why. At the faster speed, the engine has found some rpm at which the loose component is vibrating in tune with the system, instead of rattling at odds with it.”

These same frequency dynamics exist within CNC machining center operations. A machining center features a tool with a bundle of teeth that rotates at high speeds, each tool entering and then exiting a metal part. These repeating collisions cause the tool to deflect and rebound at a specific frequency. “Sweet spots” exist where the tooth-pass frequency is in tune with the harmonic characteristics of the machine tool itself. (Experienced machinists can often identify these sweet spots by ear.) Because greater depth of cut is possible when cutting is stable, more efficient machining results from finding that harmony.

But just like the car that stops rattling when driven at certain speeds, several sweet spots exist along the spectrum from the machine spindle’s lowest rpm to its highest. These sweet spots can be hard to detect, as they are typically wedged between frequency ranges that cause chatter and deflection. Tap-testing not only locates these sweet spots, it also demonstrates that safe spindle speeds reside at rpm values significantly higher than most operators would dare to use. The risk and potential cost of damaging the tool, the machine, or scrapping the part is simply too high for most job shops.

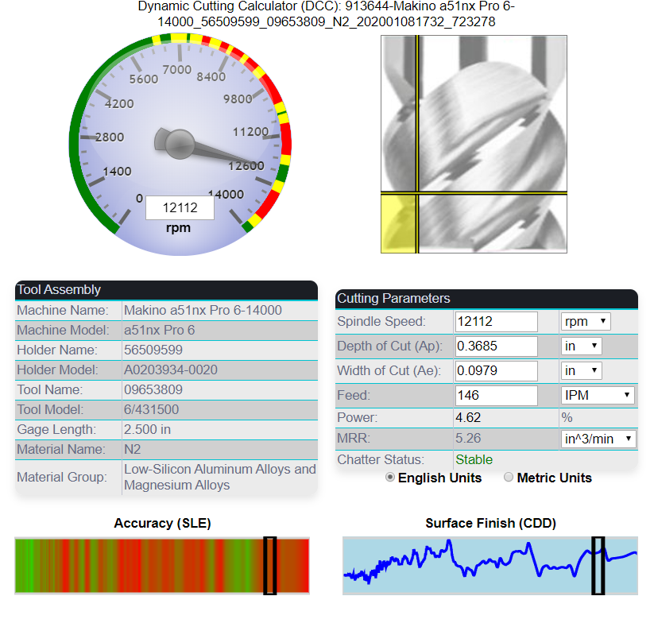

The software dashboard created by Manufacturing Laboratories Inc. includes a “speedometer” that makes the process of finding optimal feed and speed rates intuitive to a user rather than requiring expert analysis.

The test to identify sweet spots for a machine tool system is quick and relatively simple. A small sensor called an accelerometer is placed on the end of a cutting tool using a wax adhesive. When the tool is tapped with a hammer, the sensor measures the force from the hammer and the tool's reaction to that force. These measurements are fed into software algorithms that determine, based on the material and the depth of cut, which speeds are going to be stable and which speeds are not.

Manufacturing Laboratories Inc. (MLI) provides software for this analysis. The company has created a dashboard that includes an interactive speedometer, along with a picture of the tool and corresponding sliders that allow the user to experiment with the axial and radial depth of cut in search of the best possible material removal rate at a given speed.

Similar to a car’s tachometer that shows safe operating levels of the engine at various rpm, the tap-test software speedometer displays red, yellow and green zones along the lowest to highest spindle speeds. Green indicates a stable cut, yellow indicates potential chatter, and red indicates a no-go zone where the chances of chatter, stalling the spindle, breaking the tool or worse are high.

Just before the pandemic began sweeping across the country back in February, Shawn Shepard, a machinist with 35 years of experience who now works for Precision Shapes, Inc. in Titusville, Florida, was one of the first to host a visit by MSC specialists to conduct a tap-test. Precision Shapes specializes in complex aerospace part machining for both the DoD and the commercial aviation industry, and much of the company’s machining time is devoted to cutting Ti6 titanium — a process that burns through thousands of dollars’ worth of tooling per month.

When the MSC specialist conducted a tap test on the machine tool cutting these parts, the data revealed that Shepard had ample room to increase the spindle speed. Shepard says that adjusting the spindle speed to the higher rpm identified on the software dashboard gained the company 20 additional inches per minute on feed rates and eliminated two hours of cycle time for every 16 parts.

“Sometimes when we program parts offline, we tend to be babies,” Shepard says. “We try to baby our tools. We don't want the programmer or the engineer to break it, so sometimes we stick with a speed that works because we don't know any better. But for some of our longer running jobs, 20 minutes for a single part number can mean thousands of hours saved by the end of the month.”

Shepard was so excited by the results that he wanted the MSC specialist to “camp out” at Precision Shapes to test several other jobs. After all, the results from one test aren’t transferable to another job if that job’s setup utilizes a different machine, cutting tool, fixture, or part material. Each of these components carries a unique resonant frequency that has to be measured in the context of the entire system.

This was not the only issue to complicate matters — not for Shepard, Oak Ridge, MSC and everyone else involved in the CRADA. Just as the DoE initiative was getting started, and just after tap-testing proved a major success at Precision Shapes, COVID-19 shut it all down.

What Machine Shops Have in Common

Dr. Scott Smith and Dr. Tom Delio are principals of MLI, the previously mentioned company that actually began patenting technology related to impact testing of machine tools in the late 1990s. In 2002, Smith, Delio and Dave Barton co-founded a company called BlueSwarf to commercialize their discoveries to industry.

Barton left BlueSwarf in 2017, around the same time Smith was asked to consider stepping away from his mechanical engineering teaching position at the University of North Carolina, Charlotte, to create a machine laboratory at Oak Ridge — the lab that now serves as headquarters for the tap-testing collaboration project with MSC. Smith recruited a team of the top researchers in the field to come with him to Oak Ridge, including University of Tennessee professor Dr. Tony Schmitz, Dr. Nick Horvath from UNC Charlotte, Dr. Andrew Honeycutt from Makino, and Dr. Jaydeep Karandikar from GE. David Barton also works as a consultant for the project.

This group has spent their careers working with and creating technologies designed to optimize machine tools, and are strident believers that tap-testing has the potential to increase the productivity and economic stability of machine shops around the country. Indeed, this publication has written somewhat breathlessly about the potential of these technologies for many years.

Finally, in early 2020, the final puzzle piece seemed to fall in place: a way to share this technology on a national scale. The final puzzle piece? MSC.

Anyone who reads Modern Machine Shop is likely familiar with MSC Industrial Supply Co. and its “Big Book” catalog and website which, the company says, features the largest metalworking product portfolio in the industry. MSC’s vast reach extends to nearly every machine shop in the U.S., from multinational behemoths to garage shops with just one employee.

The seed of the partnership with MSC was planted when Jamie Goettler, MSC’s director of metalworking innovation, met with Dave Barton at IMTS in 2018. There, Barton showed Goettler a beta version of new software developed by Barton and Delio. The updated software included an AI-powered dashboard tool that featured a new “speedometer” designed to make the process of finding optimal feed and speed rates intuitive to a user rather than requiring expert analysis.

That meeting in September 2018, which inspired Goettler to share the news with other MSC executives in hopes of working out a partnership with MLI, took place the same month that the DoD released its 146-page assessment in response to the President’s Executive Order. Suddenly, Smith was directing the operation from Oak Ridge with Barton as a consultant, and the private partnership that had been steamrolling ahead was retooled into a public-private partnership. Not only that, it was a partnership now overseen by the Department of Energy as a means of strengthening U.S. national security and fortifying the DoD supply chain. While this fact does not alter the fundamental roles that each party plays, it certainly lends gravity to the operation. It also draws attention to the monumental scope of the task ahead, COVID-19 notwithstanding.

That’s the Program!

According to AMT — The Association For Manufacturing Technology — there are somewhere on the order of 30,000 machine shops across the United States. Generally speaking, most are small. And, generally speaking, most are underutilizing their equipment.

Dr. Scott Smith, with the breezy, well-spoken manner of the seasoned professor he is, recently explained to me the fundamental problem that Oak Ridge and MSC are trying to solve: Most shops do not understand the potential of their own equipment. Part of his riff on the subject is worth reading in full:

“The reality is that most shops are under-using their equipment because they don't know what their equipment can do. And the reason that they don't know what their equipment can do is that the performance depends on the whole system that gets put together. It's the machine tool, and then the tool holder and then the tool. It's the fixturing. And it's not until you assemble them all together that you get the system whose performance you're interested in, right? So, the spindle maker makes the spindle, the machine tool maker makes the machine, and the tool maker makes the tool. And they all sell it to you separately with no idea how you're going to put it all together. They can't tell you how to use it. But then when something goes wrong, there's a big tangled mess. You call the tool maker and they say, ‘Oh no, everybody loves our tools! They worked fine in other places so there must be something wrong with your older machine.’ And you call the holder maker and you call the machine maker and they all say, ‘Everybody loves our stuff!’ And you're still stuck.”

What machine shops are lacking, Smith says, is information. The tap-testing technology is designed to take measurements of a combined system and enable those measurements to direct what the user can and cannot do. Historically and currently, Smith says, the infrastructure for CNC machine tools is focused on geometry. “In milling operations, software writers imagine the tool as a cylinder and the workpiece as a prism. As long as the cylinder moves past the prism in all the right places, then you made your part,” Smith says.

Approaching machining as a geometry problem is a machine-agnostic process, which would be OK if all machine tools were alike and required only the correct geometries to machine a part. But it's not geometry only. Torque, power, stiffness, surface location, surface finish and fundamental physics get in the way.

Oak Ridge and MSC want to provide shops with measurements — information — that show what their assembled systems can do. This would not only increase throughput, Smith says, but also allow shops to write part programs that would work every time, because the shop knows in advance what the machine can and cannot do.

“It's not a hard measurement,” Smith says of tap-testing. “Anybody can learn to do it. But the mom and pop shops, the small shops, they may not have a dedicated IT person that they can put on this job. So, what do they do now?”

What they do now is they guess, Smith says.

Smith is not talking about blind guesses, of course. Experience matters. And the makers of tools and tool holders and spindles and fixtures already provide recommended ranges of operation. Unfortunately, Jamie Goettler says, the typical method of determining speeds and feeds is to go straight to the midpoint of those ranges. “They start there, they listen to the sound, they check the load on the load meter or the horsepower drain on the machine, they look at the part, they smell what’s around them, they might put their hand on a machine to feel the vibration,” he says “And if something doesn’t feel right, human nature is to turn it down.”

When something goes wrong during a machining operation, it is typical for the operator to send the part back to the programmer. The programmer makes adjustments, sends the part back to the machine, and two sides perform this dance for three or four cycles. “We break some tools; we scrap some workpieces,” Smith says. “Finally, we get one that works, and we say ‘OK, everybody stop! That's the program!’ And we go with that.”

The problem with this scenario is that while you will eventually find a trial-by-error program that works, the randomness of your process makes it non-repeatable.

If Oak Ridge and MSC think they have a solution to this problem, the question — and the challenge — becomes how to conduct tap-tests at 30,000 machine shops.

The answer, of course, is that they cannot, at least not within the two-year duration of the CRADA. Thankfully, if all goes according to plan, they won’t need to.

Physics is a Defense Strategy

Among the advantages of having MSC as a partner is not only the scale of testing that suddenly becomes possible due to the company’s size, but also the fact that MSC sells a broad selection of cutting tool brands. Goettler says that because of this, MSC is in a unique position to recommend certain combinations of tools that would be best suited for any given milling operation.

Dr. Andrew Honeycutt, formerly of Makino and now with ORNL, leads the tap-test training for the MSC specialists.

While calculating the number of possible combinations of machine tool, spindle, holder, fixture and setup variables would be next to impossible, if Oak Ridge and MSC keep track of every test they conduct, eventually there will be sufficient data that, via artificial intelligence and machine learning tools, interpreting different combinations of those variables becomes possible. In other words, if MSC did not measure the exact combination of tools at your machine shop, but they measured something very similar at another, the tap-test software can still estimate how your system will perform.

Over time, MSC and Oak Ridge say they can build up enough data to cover almost every conceivable combination of hardware and materials. It is another aspect of the work that Barton compares to modern online retail stores.

“Some online retailers know a lot about you, but they don't know everything about you,” Barton says. “So they look for someone who is like you, your doppelganger, and they look at what that person did that you didn't do. Then they send you a suggestion that maybe you'd like to try this other thing, right? It's a little spooky, how well it works. Our system is kind of like that. If you if you have a tool-spindle-holder combination that we haven't measured, eventually we'll be able to look back in the data and find something that's close to it and then make a solid recommendation without even making the measurement.”

That data-collection effort was just getting started when COVID-19 hit the United States. By the time the pandemic shut down most of the country this past spring, about a dozen MSC field representatives had received tap-test training at Oak Ridge National Laboratory. The plan had been to have as many as 100 MSC specialists trained and out in the field making these measurements by the end of the year. Some of that work is resuming as COVID-related restrictions have eased, and the database of testing information is growing as more MSC employees receive training and are deployed to conduct tests.

The first graduating class of MSC specialists trained by Oak Ridge National Laboratory to conduct tap-tests. Seen here are Dr. Scott Smith, seen holding the diploma, Jamie Goettler to Smith’s left, followed by Dave Barton. Incidentally, the group is standing in front of a 3D-printed Shelby Cobra replica.

But even at this early stage, the results of completed tests have been eye-opening.

“On average, we’re making improvements in machine utilization of more than a factor of two,” Goettler says, “which is amazing but consistent with what we've seen in the past.” If the collaborative agreement stays in place (it is currently in Phase 2) and the partnership proves successful, the implications for machine shops and the Department of Defense could be enormous.

“The basic idea is that we're not trying to get extremely precise predictions,” Smith says. “We're trying to get very robust answers. I want to provide the users and the mom and pop shops with testing dashboards that will work. So when they write their NC programs, they consult the dashboard, and the programs work right the first time because we're basing them not just on geometry but also on the physics.”

From a national defense perspective, the DoD relies on shops around the country that make small volume, high variability parts — the kind of production where there is little opportunity to dial in your processes. While a company like General Motors might be able to experiment with machine tool parameters and potentially scrap several parts along the way, most shops do not have this luxury.

“I think with the events early in the pandemic, the fragility of the supply chain became even more evident,” Smith says. “If you don't have machine tools to make tooling such as molds, and the molds to make masks, then you have to rely on someone else to send you masks — if they feel like it. That certainly is worrisome, and it's been worrisome to the DoD for some time.”

“We need we need to move quickly to address these issues,” Goettler says. “We're able to improve shops’ current tooling and processes so significantly that we think we can close that gap when it comes to domesticating the supply chain. In many cases this technology alone can bridge that cost gap.”

“That is why we're doing this,” Barton says. “Scott, Tom and I have been working together for a quarter century. This is the culmination of a career’s worth of work. Finding a partner like MSC that has the scale and the reach and the technical knowledge to do that was very significant. It was not done lightly. This technology will allow us to make a large impact very quickly, and it’s important to us to see this through to make sure it has the impact we know it can.”

Related Content

Ceratizit Product Update Enhances Cutting Tool Solutions

The company has updated its MaxiMill 273-08 face mill, WPC – Change Drill, as well as the HyPower Rough and HyPower Access 4.5-degree hydraulic chucks.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreNidec Universal Head Enables Versatile Machining

The compact universal head enables better accessibility between the tool and the workpiece, as well as improved surface-finish quality, greater motion range and high-efficiency machining under ideal machining conditions.

Read MoreSandvik Coromant Milling Tool Boosts Productivity in Steel Machining

CoroMill MR80 is designed for challenging roughing operations in a wide range of face and profile milling applications in steel and stainless steel.

Read MoreRead Next

Optimized Machining out of the Box

Four tooling-related companies partner to supply dynamically stable milling for improved productivity on existing machine tools. Users do not have to measure the dynamics of their machines. Instead, tooling tailored to the machine arrives as a complete assembly, along with software for quickly determining the parameters that tooling can be used to achieve.

Read MoreOEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More