Share

When it comes to additive manufacturing (AM), the U.S. Marine Corps confronts extreme versions of the opportunity and the dilemmas that many machine shops face.

The opportunity: AM—particularly in metal—offers a promising way to obtain short-run parts in a hurry. For a business, the benefit is merely filling the order rapidly. But for the Marines, the benefit might be winning the battle by replacing a broken component to restore a crippled piece of equipment to use.

But the dilemmas are these: Metal AM systems are generally costly, bulky relative to the size of parts they produce and difficult to use given the safety considerations necessary for handling powder metal. These factors are problematic for a machine shop, and prohibitive when it comes to the hope of letting the Marines use metal 3D printing in the field.

And for the Marines, one more concern is that metal 3D printing ought to operate in conjunction with CNC machining within a single setup, for the sake of truly obtaining the part as fast as possible. That is, the Marines’ interest is in “hybrid” AM combining additive and subtractive operations. For all these reasons, a small CNC milling machine with an add-on metal 3D-printing head comprises the heart of a system the 1st Marine Logistics Group (MLG) at Camp Pendleton, California, is evaluating for making repairs and replacements to hardware items in the field, far from traditional supply chains. The additive/subtractive machine tool, along with two polymer 3D printers, operates within a self-contained hybrid additive manufacturing facility the Marines refer to as the “ExMan” unit, which is short for Expeditionary Manufacturing. The ExMan represents potentially the most effective resource yet for enabling deployed personnel to be self-sufficient in providing for their own critical hardware needs. In addition, the 1st MLG’s experience with it offers a model for how an established manufacturer might proceed with additive, because the Marines are following a learning curve comparable to what a machine shop might expect.

One example of this relates to recognizing the use cases. Gunnery Sgt. Travis Arndt is part of the team developing and evaluating the capabilities of the ExMan. “Having hardware supplies at the point of need is always a problem,” he says. For instance, a broken steering-column pinion gear might render a Humvee inoperative, but obtaining this replacement part far forward in the field fast enough to matter might be close to impossible. To respond to problems like this, Marines have long done manufacturing in the field. Existing portable machine shops offer milling or turning capabilities. Yet a part like a pinion gear is too challenging for systems such as these, for multiple reasons. The part is too complex to make on a lathe or mill in an exigent setting, and carrying enough raw material to be prepared to make a part such as this would represent a problem in itself, since machining a shaft with gear teeth out of solid stock would mean cutting a lot of material away. Now, Gunnery Sgt. Arndt says, the challenge and the opportunity of metal AM lies in the mindset change necessary to reevaluate challenges such as this. Marines—just like shops adopting AM—need to rethink long-standing assumptions about what kinds of parts can now be fabricated quickly.

Another telling discovery the Marines have made relates to personnel. The additive capability advances best through the efforts and imagination of those most interested in exploring it, not necessarily through the application of any preexisting skill. Nine people from the 1st MLG so far have been trained on the ExMan system. Those with the requisite “innovative mindset,” in Gunnery Sgt. Arndt’s words, have tended to self-select, volunteering for this opportunity. The result has been a diverse mix of skill areas, with machinists, auto mechanics, electronics technicians, calibration technicians and welders now all using the system. All are capable of thriving and innovating with it, and, in fact, the diversity has proven valuable for finding applications in which additive can be effective. Is hybrid metal AM a part-making resource, a tool-making resource, a resource for repair? It depends on the need, and it depends on the perspective of the particular user thinking about this capability.

Deposition Without Special Protection

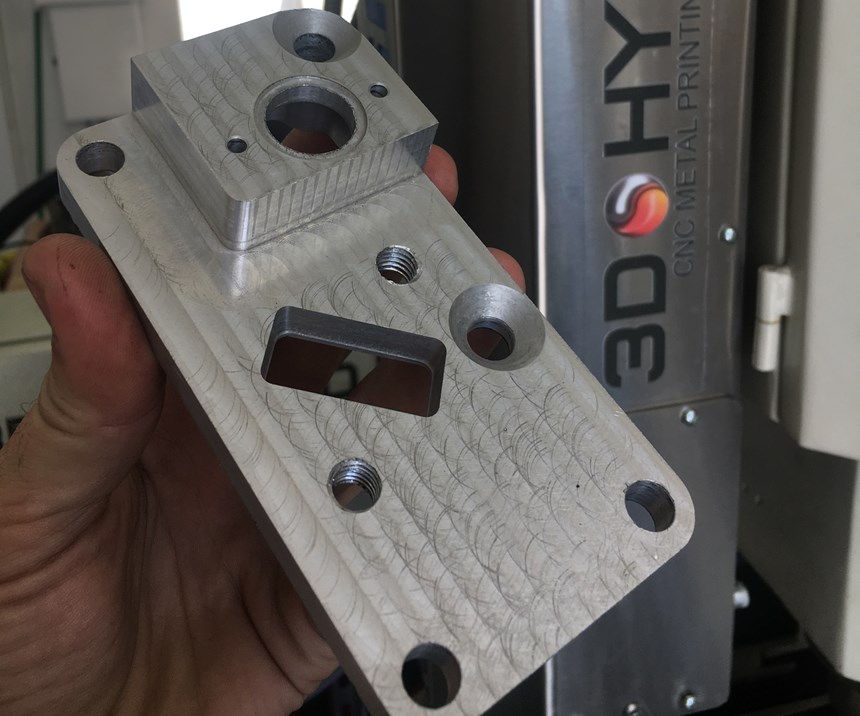

Gunnery Sgt. Arndt’s team began the search for metal 3D-printing capability in response to a Marine Corps initiative to bring additive manufacturing as far forward into battle as possible. The search was stymied at first, because powder-bed selective laser melting systems were seen to be unsuitable for deployment and use in the field, given their cost, size and safety requirements. The Marines instead found the answer they believed they were looking for when they met Karl Hranka, founder of California startup 3D Hybrid Solutions, which supplies add-on heads for metal 3D printing via various methods of metal deposition, including laser melting of powder spray, arc melting of wire feed, and high-velocity cold spray of metal powder. In the ExMan, the wire-fed metal 3D-printing head mounts parallel to the spindle on a milling machine from Tormach, producing a system that can build 3D features and then mill and drill them to precise tolerances within a single setup. The additive capability requires no special personal safety protection because the input material is solid wire instead of powder and because current is used to melt the material rather than a laser. The safety measures needed are eye protection plus fume extraction like that of gas metal arc welding. Mr. Hranka says, “It’s not a normal arc-welding process, which generally includes some level of porosity, but instead a lower-heat approach that enables effective deposition of metals at full density.”

This 3D printing by deposition, meaning placing metal along a precise tool path rather than using a powder bed, means a complete 3D part can be built up onto a flat surface. It also means a 3D feature can be built just as easily onto an existing part, with the existing part used as the starting work surface. In short, hybrid manufacturing is a resource for repairing or modifying existing components every bit as much as a resource for making components from scratch.

“The repair opportunity is huge,” Gunnery Sgt. Arndt says. For the Marines, it compels perhaps the most fundamental mindset change. “Our thinking now is, if something is broken, don’t throw it away,” he notes. “Instead, we think about how we might repair it.” Recent experiments have focused on field-repair of vehicle piston heads. Testing the resilience and capability of the additive system is part of the Marines’ experimentation, but an even bigger part is developing practice at spotting opportunities for hybrid AM to keep parts in use longer that might otherwise be discarded. In this way, the ExMan is already aiding and saving cost for the Marines at Camp Pendleton, even though it has yet to be deployed.

In fact, in at least one notable case, the ExMan provides a valuable alternative to existing supply. Gunnery Sgt. Arndt points to unmanned aerial vehicles—drones. These devices are still new, and prone to break frequently. As yet, there is no formal supply chain for needed parts, because there is no understanding yet of what replacement parts are key or how frequently they will be ordered. As a result, some needed parts have a lead time longer than one year. In response, the Marines have been keeping drones flying by making needed parts through 3D printing.

Meanwhile, Gunnery Sgt. Arndt has been exploring the problem of the pinion gear. Is it now possible to solve a problem such as this one in the field? That is, is it possible to return the Humvee with this problem back to use quickly? The component is too difficult to make through machining alone, but perhaps straightforward to make through hybrid AM. For example, what about 3D printing gear teeth onto a piece of metal tubing? The “innovative mindset” he refers to consists simply of this: Recognizing that many formerly prohibitive challenges are no longer prohibitive when additive is added to machining.

Related Content

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

Read MoreThe Benefits of In-House Toolmaking

The addition of two larger gantry routers has enabled a maker of rubber belting products to produce more tooling in-house, reducing lead times and costs for itself and its sister facilities.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreRead Next

OEM Tour Video: Lean Manufacturing for Measurement and Metrology

How can a facility that requires manual work for some long-standing parts be made more efficient? Join us as we look inside The L. S. Starrett Company’s headquarters in Athol, Massachusetts, and see how this long-established OEM is updating its processes.

Read More