Milling With Waterjet

Machine with abrasive waterjet and control the depth of cut. For the right parts, this fledgling process may offer a compelling alternative.

Share

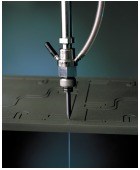

Abrasive waterjet cutting can be used for milling. The process that typically cuts edges, slots, and holes can also be used in controlled-depth applications where the jet doesn't pass all the way through the workpiece. In other words, it can mill surfaces. It can even be used to mill out pockets.

This may come as a surprise. It's less of a surprise to waterjet machine maker Flow International (Kent, Washington). For several years now, researchers at this company have been experimenting with abrasive waterjet as a milling tool. And though no waterjet milling machine has yet resulted from this research, the company says it does now have the process expertise to build one. For now, the company is talking to potential users and trying to gauge the market interest in this process.

Dr. Mohamed Hashish is the researcher who has led the development of waterjet milling at Flow. "At this point, any waterjet milling system would be a custom build," he says. But if the company finds high demand for this process in any particular metalworking segment, then a standard waterjet milling machine designed around the needs of that group will soon follow.

Such a machine would use the same nozzle, jet and garnet abrasive as a conventional abrasive waterjet machine. The difference would be in the way the machine moves. Milling with waterjet involves moving the workpiece past the nozzle so fast, the amount of material removed can be precisely controlled. This generally means mounting the workpiece on some spinning surface while the nozzle moves in a straight line. Then, completing the milling process is a piece of hard tooling—a mask. The mask lays over the workpiece like a stencil, allowing the waterjet to mill only certain regions. Where the mask has a hole in some given shape, the waterjet mills a pocket to that same shape in the workpiece beneath it. The depth is determined by the number of passes the workpiece makes under the jet. This depth can be held to an accuracy of ±0.002 inch.

What kinds of machined parts make the best candidates for this process? Dr. Hashish says the list includes parts whose material and/or geometry make traditional milling problematic.

For example, the workpiece may be made of some difficult-to-machine material like titanium, Inconel, or another aerospace metal.

Or, the difficulty may come from the geometry. The pocket may have thin walls that are difficult to mill without deflection, or acute internal corners that are just plain difficult to mill.

In any of these cases, the new alternative—milling with a jet of water carrying garnet abrasive—may well be a diamond in the rough.

Waterjet Basics

This non-traditional application of abrasive waterjet may interest some to whom waterjet machining is an unfamiliar process, so here is a brief primer:

Abrasive waterjet machining can be thought of as a water-driven grinding process. A narrow, high-pressure jet of water carries particles of garnet abrasive at speeds ranging from 1,000 to 2,400 feet per second. This garnet does the cutting. And there are few materials, metal or non-metal, that cannot be cut in this way. In metalworking, abrasive waterjet machining often finds work cutting hard steels, aerospace alloys, and other materials that are difficult to machine through a more conventional, mechanical cutting process. However, waterjet machining also offers other advantages. One is that it's a "cool" process. Because there is no heat-affected zone, waterjet is a candidate for applications where thermal-induced micro-fractures or distortions in the part are unacceptable.

This article uses "waterjet" and "abrasive waterjet" interchangeably, but it's worth noting that the terms are not necessarily synonymous in larger contexts. There is such a thing as pure waterjet cutting used outside the metalworking industry. But in the context of machining metals and other hard materials, "waterjet machining" can be assumed to mean abrasive waterjet machining, with the hard garnet particles added to the jet.

Historically, controlling a waterjet's depth of cut has been difficult. That's why waterjet machining is typically used in applications where depth of cut doesn't matter. These include applications where the jet passes all the way though the workpiece, like slotting, drilling, and machining cut-outs. Machining when the jet does not pass all the way through has traditionally been limited to "artistic" purposes, like etching and labeling.

Waterjet milling does add control over depth of cut. Thanks to this addition, waterjet cutting when the jet does not pass all the way through can be used not just for appearance effects, but also to produce features that are functional.

Rotary Motion

Flow experimented with several approaches to achieving this depth control. These included using a weaker jet, as well as dynamically affecting the jet through pulsing or changing its parameters on the fly. In general, these techniques proved impractical. Instead, the most effective approach was found to be the simplest one: moving the workpiece under the nozzle fast enough that the jet can only remove a small amount of material at a time. For example, moving a titanium workpiece at a speed of around 900 feet per minute results in a milling depth of cut of about 0.001 inch per pass.

Achieving this kind of speed inevitably involves some sort of rotary motion. There are two possible approaches. One is to place the workpiece—or several workpieces at once—on a large turntable. While the table spins, the nozzle moves along the radius like the needle of a record player. The other approach is to mount one or more workpieces on the surface of a spinning cylinder—either the outer or inner surface. The nozzle then moves parallel to the axis of rotation, similar to the way a lathe tool would move during an OD or ID cut, respectively.

Whichever approach is used, one distinct advantage of waterjet milling is that its efficiency is relatively unaffected by batch size. The process is well-suited to machining many parts at once. Whether one part or many parts are mounted on the spinning surface, the cycle time may well be the same. In addition, these parts do not even have to be identical. The geometry of the milled part comes not from any variations in the machine's toolpath, but from the geometry of the mask. Therefore—so long as all of the masks are ready—a batch of all-different parts could be milled in one cycle, just as easily as a batch of identical parts.

Process Advantages

The mask is made from a material that is more resistant to erosion from the abrasive waterjet than the workpiece itself. A steel mask can be used for aluminum or titanium workpieces. Other workpiece materials may call for a tungsten carbide mask.

The need to machine this mask before any waterjet pocketing can be performed has to be figured into any economic justification for this process. The mask does wear out. For instance, the steel mask cited in the application example (see Sidebar) is good for three parts. Therefore, one-third of the cost of producing this mask would be added to the direct cost of waterjet milling the part to determine the true unit cost.

Because it is solely the geometry of this mask that determines the geometry of the workpiece, complex geometry does not add to the difficulty or expense of the waterjet milling process. This gives the process an advantage over mechanical milling, where certain features add to the difficulty and cycle time. For example, acute internal corners may require time-consuming light cuts with small-diameter tools. And thin walls may require similar light cuts to machine them without deflection. But in waterjet milling, considerations like these disappear. As long as the features are in the mask, corners can be machined as easily as straight walls, and thin walls can be machined without any lateral deflection.

However, mechanical milling can achieve a much better surface finish. Says Dr. Hashish, "With waterjet milling, about the best finish we can achieve economically is 120 microinches."

He says waterjet milling also competes with chemical milling. Against this environmentally-unfriendly process, waterjet milling may one day offer a compelling alternative. In addition to the disposal considerations, the waterjet process also offers functional advantages, he says. Among these are that waterjet milling makes it easier to vary the milling depth for different regions of the workpiece. Another advantage is that waterjet is not sensitive to the workpiece material. Forgings, heat treats and composites all can be milled effectively using waterjet.

Still another advantage over chemical milling, he says, is that waterjet milling makes it possible to control surface finish. A 120-microinch finish may be the smoothest surface possible, but for jobs demanding a finish rougher than this, abrasive waterjet makes it easily possible to vary the surface finish accordingly.

Related Content

Orthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read MoreAutomation is for Everyone

Not just for large shops, automation can help even the smallest shops solve labor challenges and become more profitable and efficient.

Read MoreAddressing Manufacturing Challenges with Automation

GrayMatter Robotics’ Physical AI robotic cells for manufacturing offer immediate impact and results.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read More

.jpg;width=860)